Multi-angle corner of heat-insulating window

A multi-angle, corner technology, applied in the direction of windows/doors, corner joints/side joints, building components, etc., can solve the problems of processing and management and installation trouble, to simplify the production and processing process, reduce the variety and complexity, expand the The effect of using the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

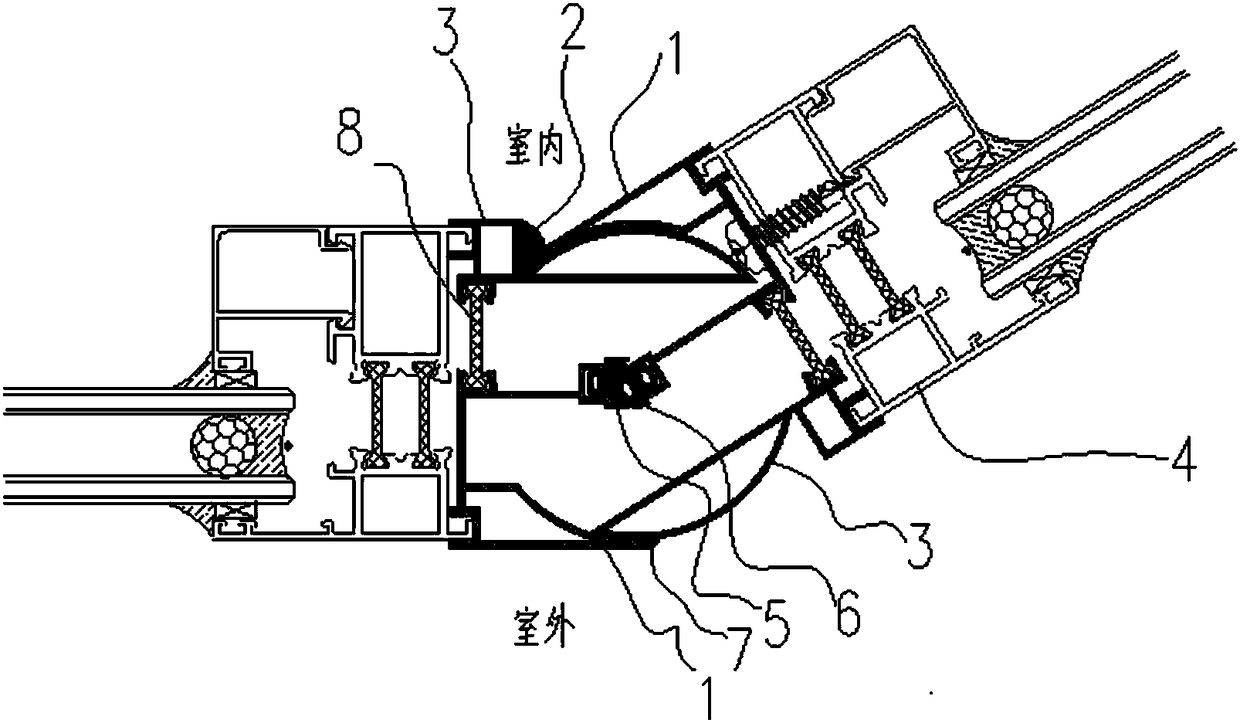

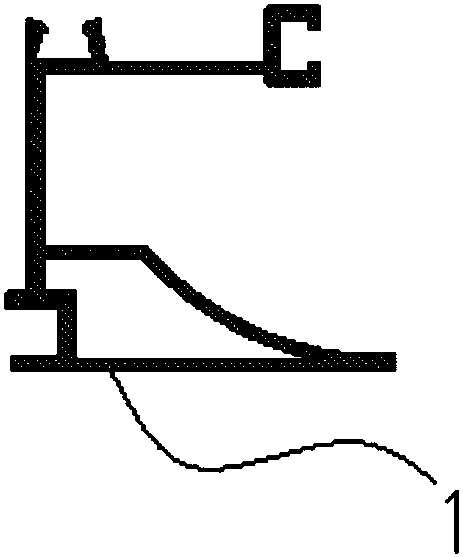

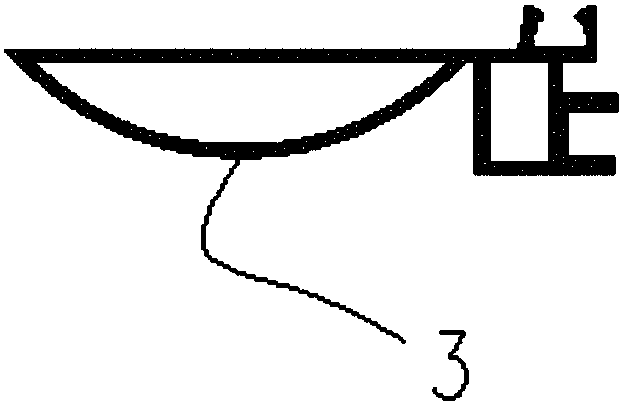

[0024] Such as figure 1 As shown, a multi-angle corner of a thermal insulation window includes two sets of concentrically rotating rotating parts and a heat insulating strip 8 arranged between the two groups of concentrically rotating rotating parts for forming a heat-insulating air space layer. The rotating parts include Rotation piece I3 and rotation piece II1, one end of the rotation piece I3 is provided with an outer cylindrical surface matching with the rotation piece II1, the other end is provided with a card slot I connected with the heat insulation window, and one end of the rotation piece II1 is provided with a The inner cylindrical surface matched with Ⅰ3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com