Insulated sliding window

A sliding window and thermal insulation strip technology, applied in the sliding window field, can solve the problems of water seepage, waste of main and auxiliary materials, air leakage, etc., and achieve good thermal insulation performance, ensure wind pressure resistance, and ensure the effect of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

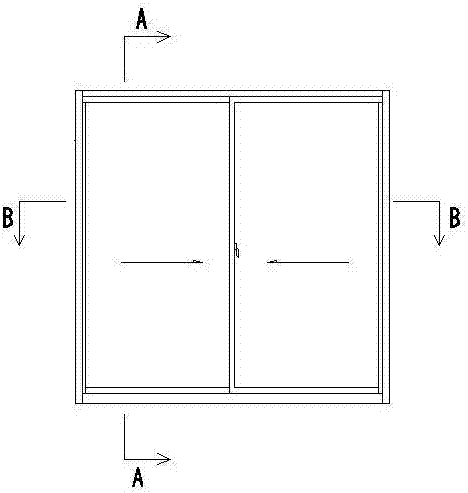

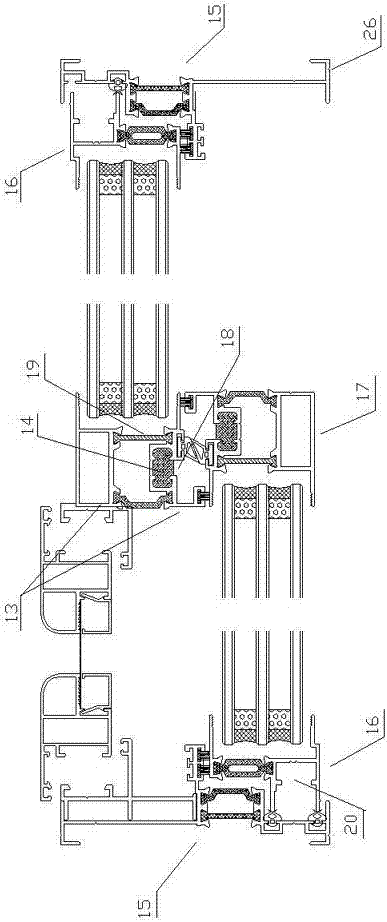

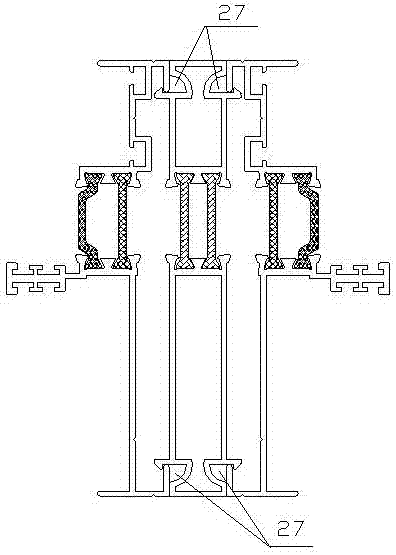

[0023] refer to Figure 1-5 , a heat-insulating sliding window, comprising a window frame and an inner and outer sash, the window frame is provided with an upper slide 3, a lower slide 12 and a left and right border 15, and the inner and outer sash is provided with an upper 1, an outer lower 6, an inner lower 2, a light 16 and Hook 17; the upper slide 3, the lower 12, the frame 15 and the top 1, the outer bottom 6, the inner bottom 2, the light 16, and the hook 17 of the inner and outer sash are all spliced by two inner and outer profiles 13 through the heat insulation strip 19 Each profile is provided with a threading slot for clamping the ends of the 19 heat-insulating strips, and there are two heat-insulating strips 19 bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com