Ultra-high performance concrete column permanent formwork and preparation method thereof

An ultra-high-performance, permanent formwork technology, applied in columns, piers, pillars, etc., can solve problems such as low cracking load, decreased durability, and reduced mechanical properties, and achieve increased structural bearing capacity, excellent durability, and economic benefits. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The outer dimension of the permanent formwork for the ultra-high performance concrete column described in this embodiment is a cylinder with a diameter of 600 mm and a height of 1500 mm. The concrete of the ultra-high performance concrete cylindrical permanent formwork adopts RPC active powder concrete with a thickness of 50mm.

[0043] The shape of the dent is strip. The width of the indentation is greater than the maximum particle size of the ultra-high performance concrete layer, so as to ensure that the groove can be filled with post-cast concrete.

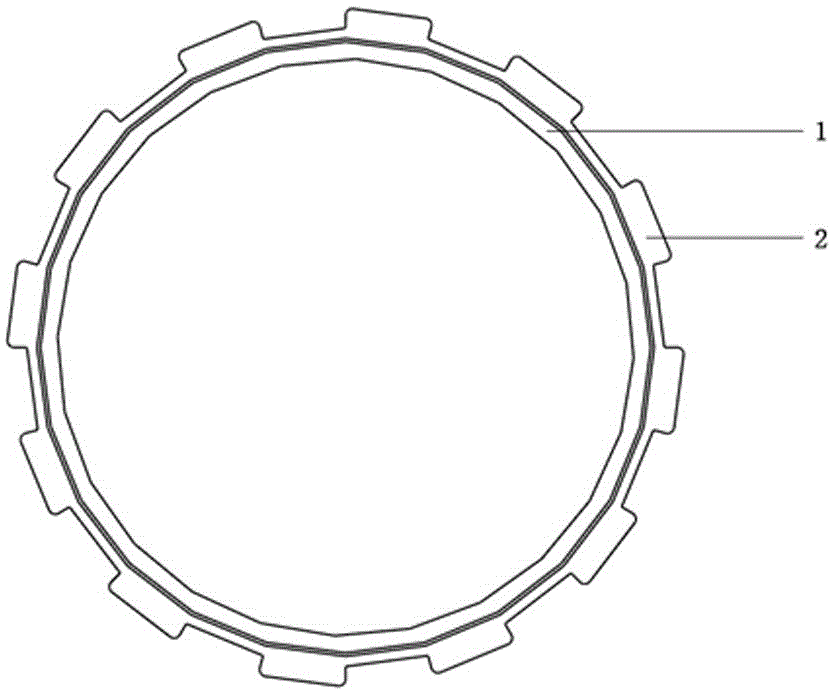

[0044] like figure 1 and figure 2 Shown, the implementation steps of its preparation method are as follows:

[0045] 1) According to the column size, reinforcement ratio and protective layer requirements, design and manufacture permanent formwork reinforcement cage;

[0046] 2) placing the reinforcement cage in the outer mold;

[0047] 3) Place the cylindrical iron inner mold 1 inside the annular rubber airbag 2, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com