Oiling device for polylactic acid fiber spinning

A polylactic acid fiber and spinning technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve problems such as not having

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

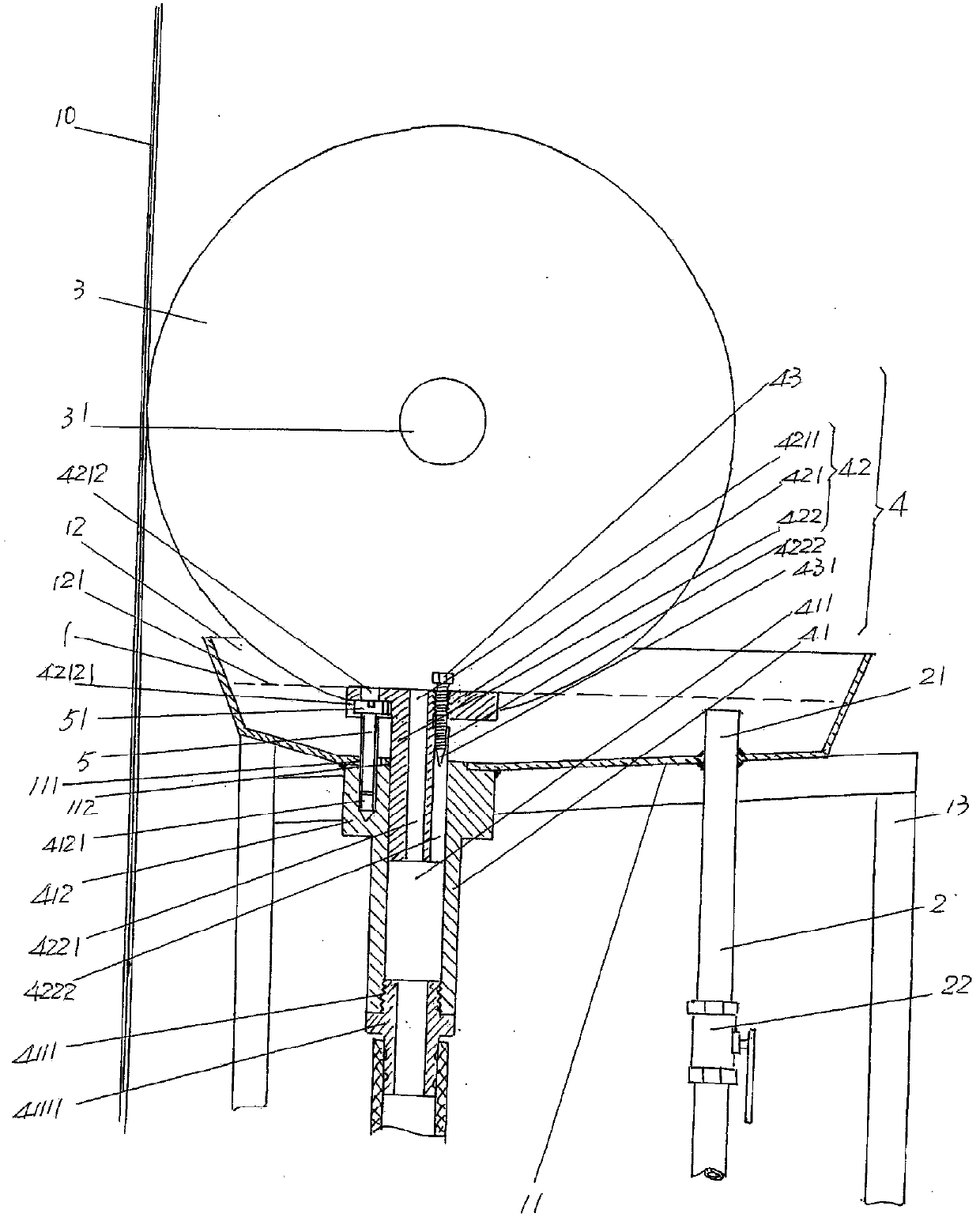

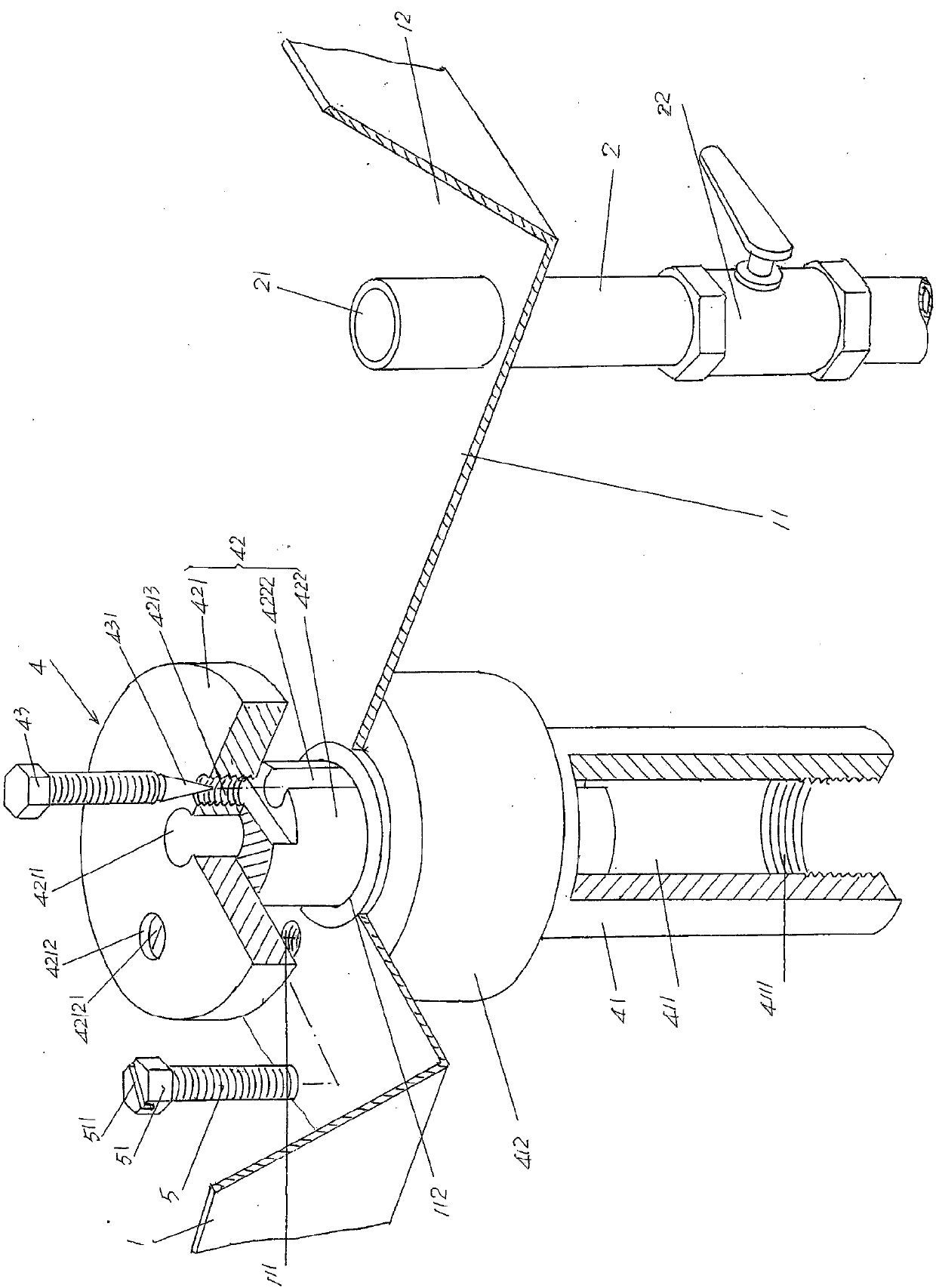

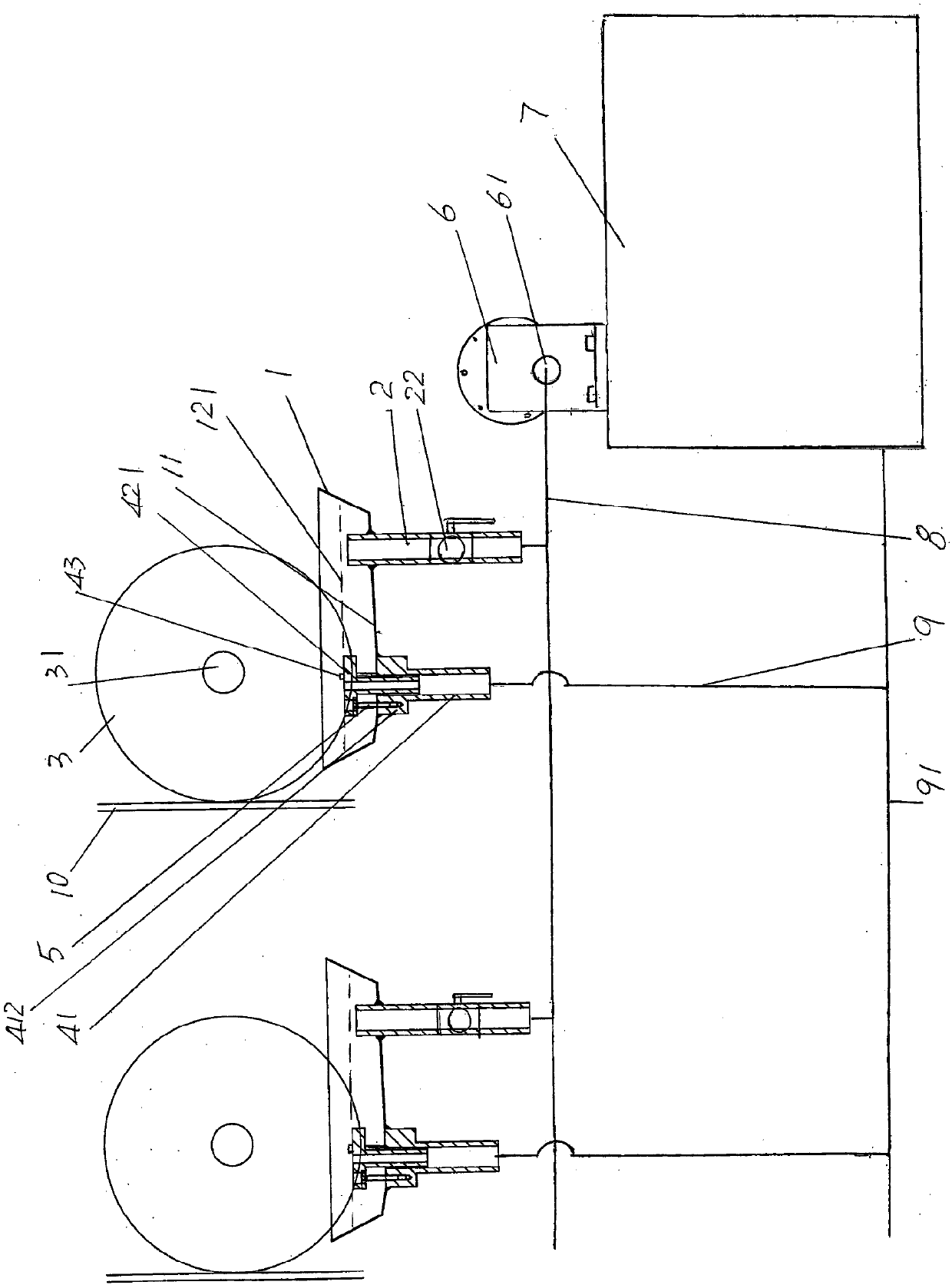

[0033] See figure 1 , shows an oil pan 1, and this oil pan 1 is supported on the oil pan support 13; shows an oil pan 1 for providing oil and in use with the oil pump 6 ( image 3 The oil supply pipe 2 connected to the oil pan is welded to the bottom plate 11 of the oil pan 1, and the oil outlet 21 of the oil supply pipe 2 is inserted into the oil pan In the oil pan cavity 12 of 1; Show an upper oil wheel 3, this upper oil wheel 3 is supported on the frame of the polylactic acid spinning machine by its upper oil wheel shaft 31 rotationally at the position corresponding to the above oil pan 1 , the upper oiler shaft 31 is in transmission connection with the upper oiler driving device (not shown in the figure) and the lower part of the upper oiler 3 penetrates into the aforementioned oil pan cavity 12 .

[0034] As the technical gist of the technical solution provided by the present invention: the structural system of the aforementioned oiling device also includes an oil pan o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com