A ring -shaped iron boron surface pre -processing equipment

A surface pretreatment, neodymium-iron-boron technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of wasting cleaning agents, incomplete pretreatment, etc., and achieve good cleaning and saving The effect of detergent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

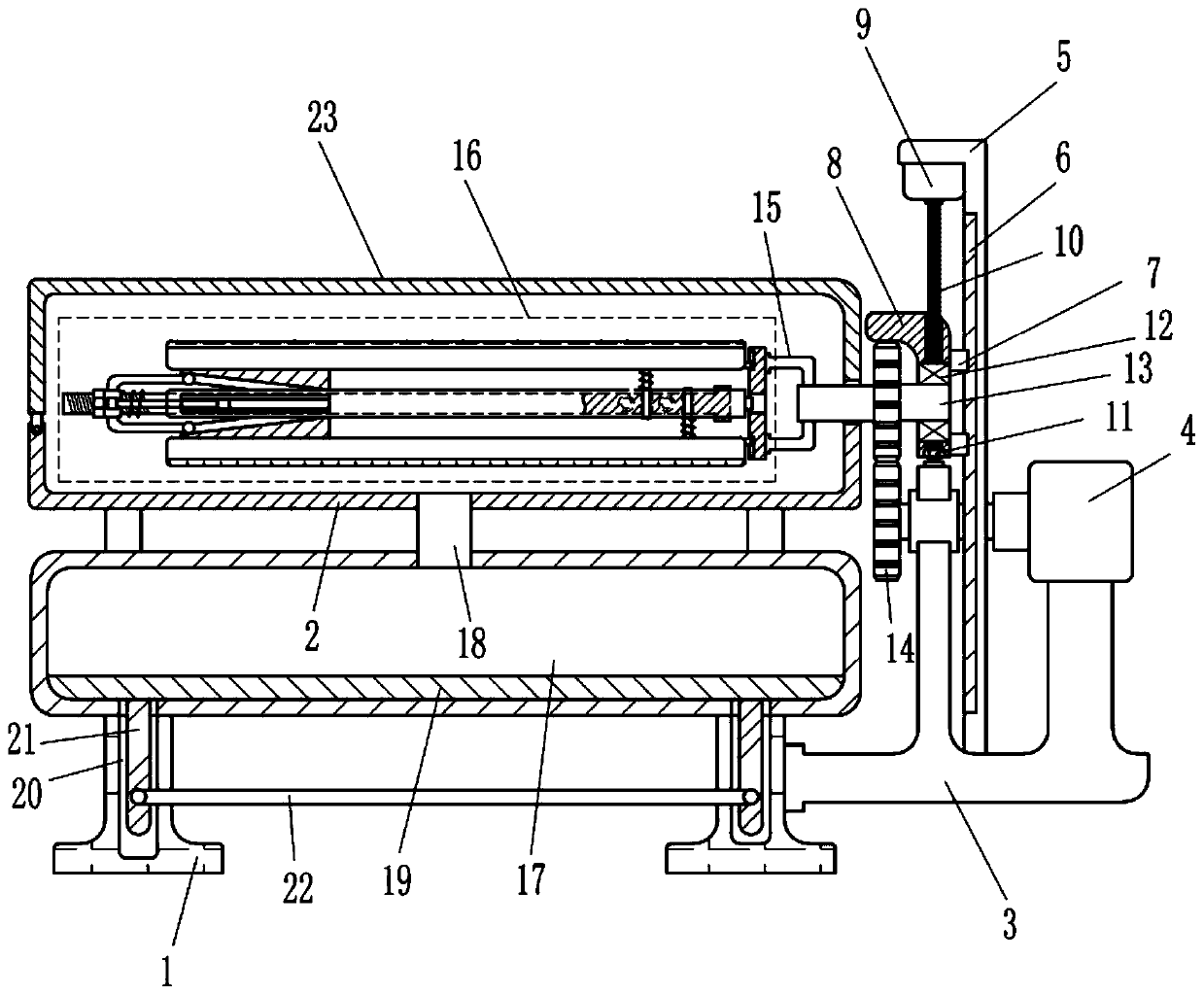

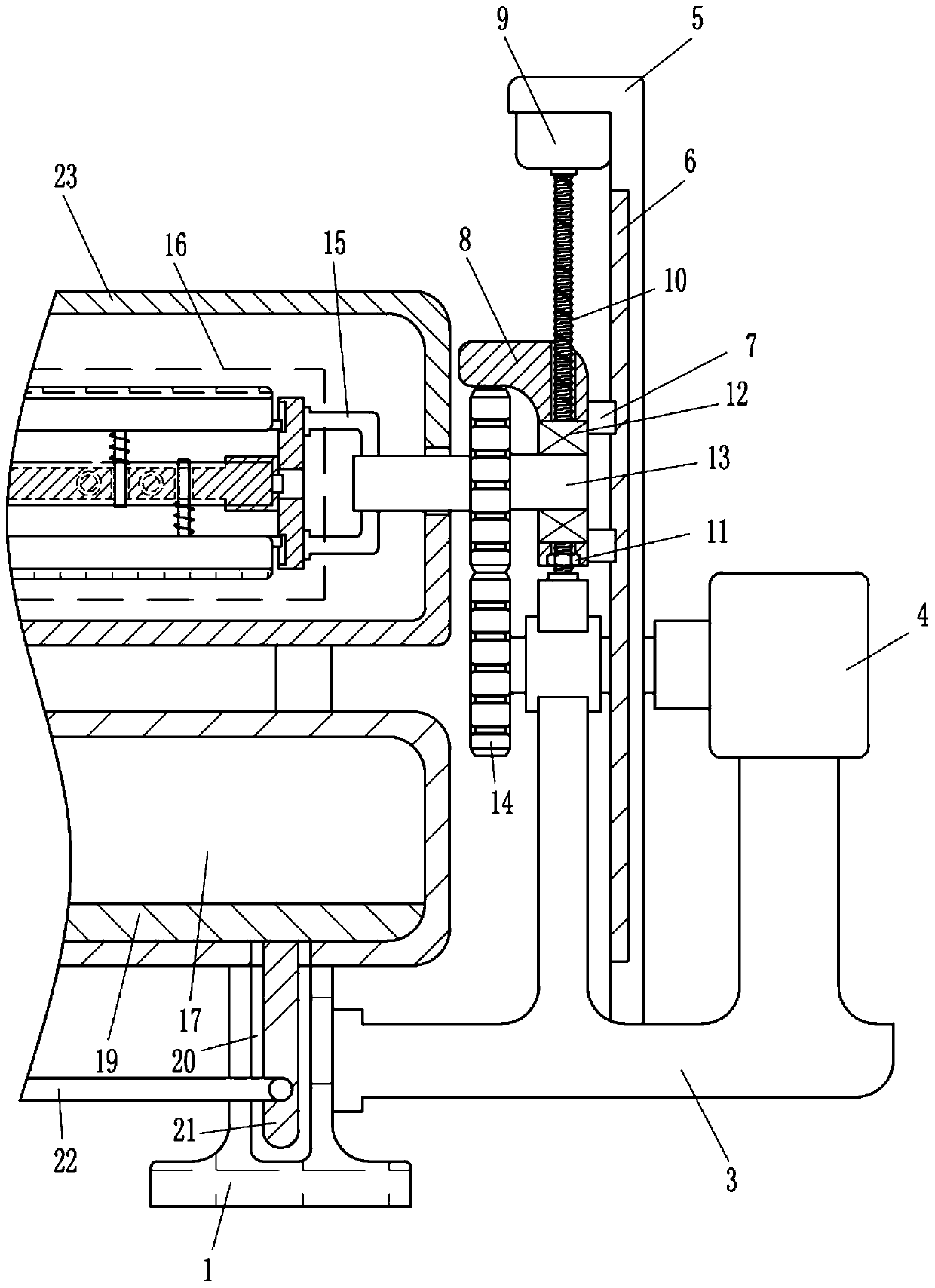

[0024] A ring-shaped NdFeB surface pretreatment equipment, such as Figure 1-6 As shown, it includes a support 1, a frame body 2, a bracket 3, a geared motor 4, a lifting device, a rotating device and a fixing device 16. The top of the support 1 is provided with a frame body 2, and the right side of the support 1 is installed There is a bracket 3, on which a deceleration motor 4 is installed, and a lifting device that drives the ring-shaped NdFeB to lift vertically is installed on the said bracket 3, and a lifting device that drives the ring-shaped NdFeB by rotating A rotating device for pretreatment of iron and boron. A fixing device 16 for fixing NdFeB is installed on the rotating device. The fixing device 16 and the frame body 2 partially overlap in the vertical direction.

[0025] When using this equipment for pretreatment of ring-shaped NdFeB, the lifting device first drives the rotating device and the fixing device 16 to move upwards, and then fixes the ring-shaped NdFeB...

Embodiment 2

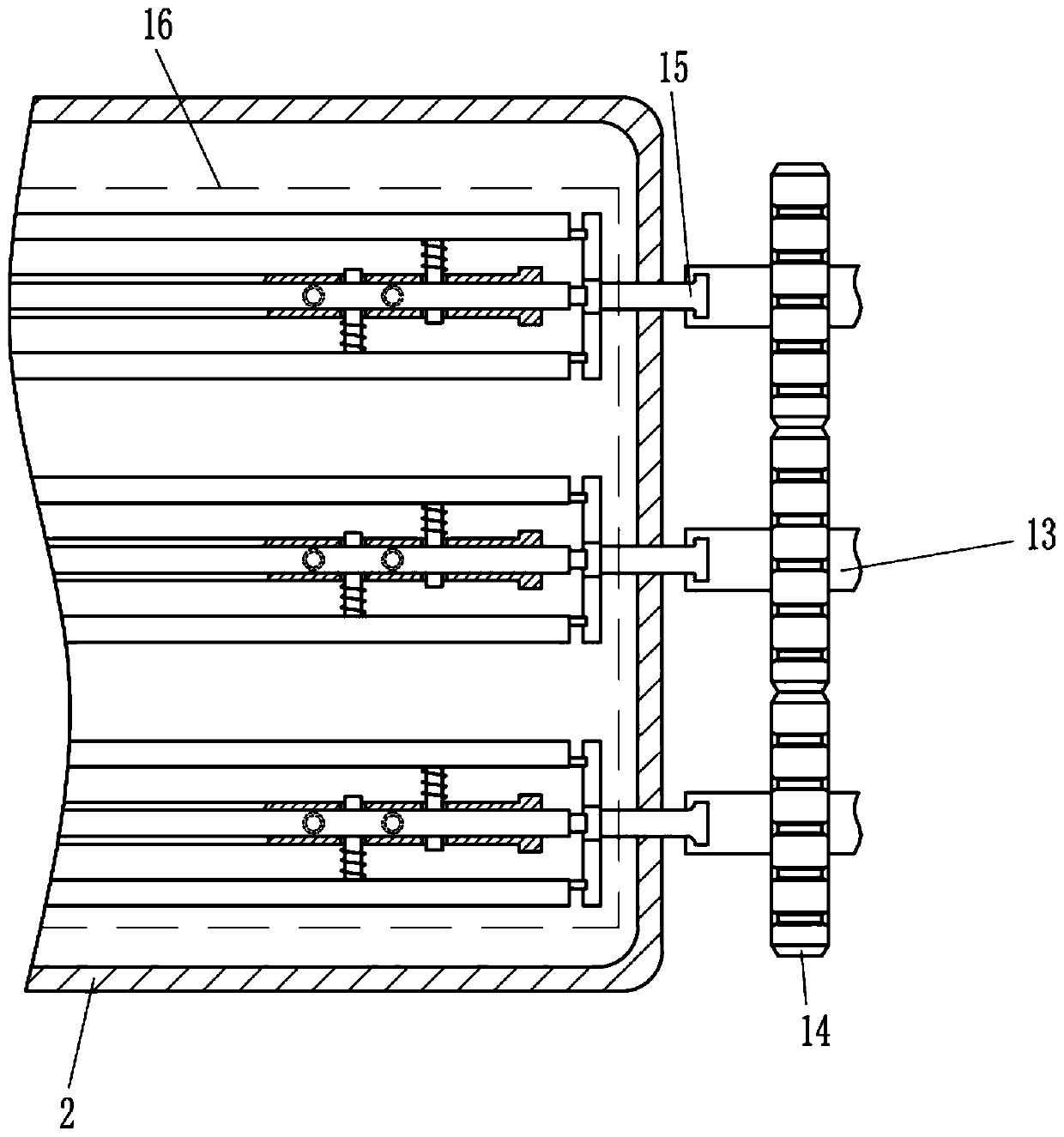

[0029] Such as Figure 1-2 As shown, the rotating device includes a bearing seat 12, a rotating shaft 13, a gear 14 and an L-shaped connecting rod 15. Three bearing seats 12 are installed on the lifting plate 8, and a rotating shaft is connected to the bearing seat 12 through a bearing. 13. Both the rotating shaft 13 and the output end of the reduction motor 4 are interference-connected with a gear 14, and the gears 14 mesh with each other. Two L-shaped connecting rods 15 are arranged on the outer side of the rotating shaft 13, and one of the L-shaped connecting rods 15 A fixing device 16 is connected between them.

[0030]When it is necessary to drive the fixing device 16 to rotate to pretreat the annular NdFeB, the control needs to move the lifting plate 8 and its upper device downward until the gear 14 on the rotating shaft 13 and the gear 14 on the reduction motor 4 mesh, and then The user controls the rotation of the reduction motor 4, which drives the gear 14 to rotate,...

Embodiment 3

[0034] Such as figure 1 As shown, it also includes a water inlet pipe 18, a piston 19, a connecting rod 21 and a concave connecting rod 22, a cavity 17 is opened in the support 1, and a water inlet pipe 18 is connected to the top of the support 1. The water pipe 18 connects the frame body 2 with the cavity 17. The cavity 17 is provided with a piston 19 that slides up and down. The left and right sides of the lower part of the support 1 are provided with guide grooves 20. The left and right sides of the bottom of the piston 19 Both are provided with connecting rods 21 , the connecting rods 21 pass through the guide grooves 20 , and concave connecting rods 22 are welded between the connecting rods 21 .

[0035] When injecting the cleaning agent into the frame body 2, the cleaning agent in the frame body 2 enters the cavity 17 through the water inlet pipe 18, and when it is necessary to adjust the liquid level of the cleaning agent in the frame body 2, the concave cavity can be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com