High-precision bio-compound 3D printing device and printing method

A 3D printing, high-precision technology, applied in the field of biological 3D printing, can solve the problems of poor mechanical strength, unfavorable organ development and functional expression, large differences between microscopic scale and cells, etc., to improve mechanical strength, suitable for adhesion growth, guaranteeing Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

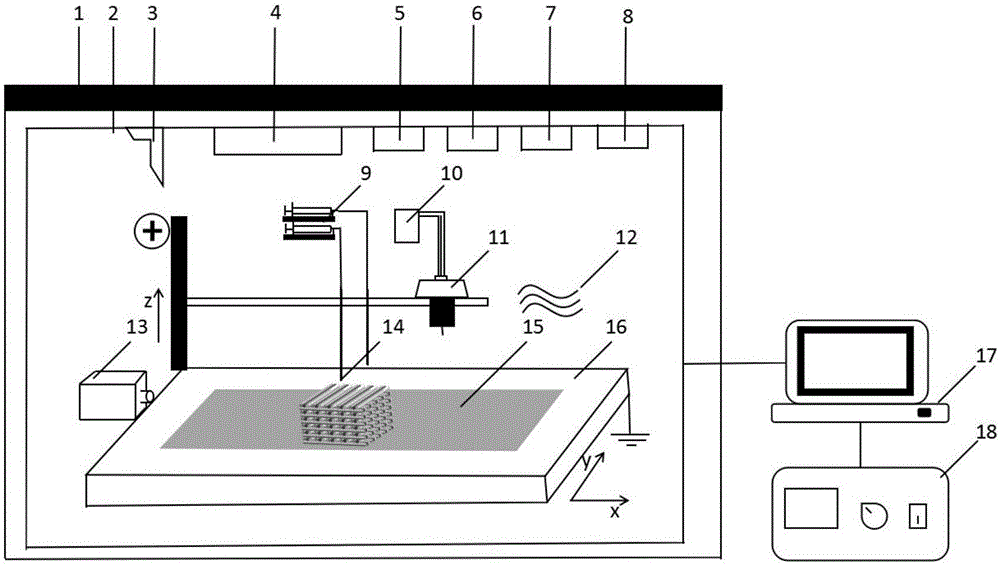

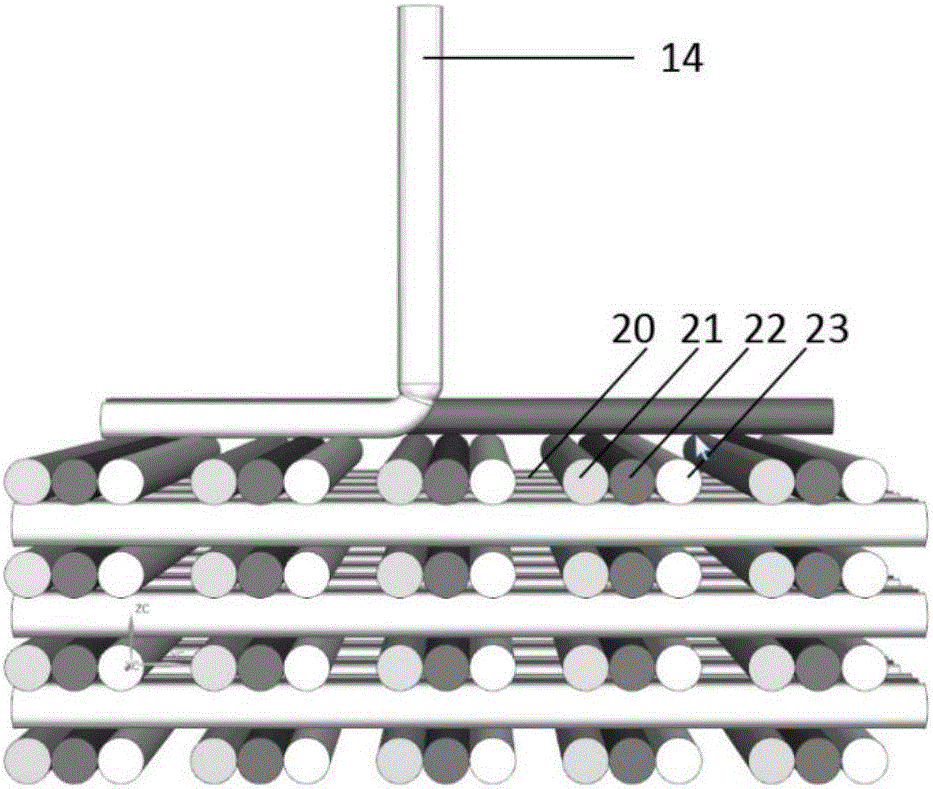

[0034] refer to figure 1 , a high-precision bio-composite 3D printing device, including an ultra-clean test bench 1, a device housing 2 placed inside the ultra-clean test bench 1, a printing platform 16 is provided inside the housing 2, the printing platform 16 is grounded, and the printing platform 16 is connected to the motion control The modules are connected, and the printing platform 16 can move in both directions of XY. The device 11 is connected to the motion control module and can move in the vertical direction of the Z axis. The cell printing nozzle 14 is connected to the ultra-precision syringe pump 9 for storing the cell solution. The molecular polymer reflow heating device 10 is connected, and the shell 2 is equipped with an atomizer 3 compatible with printing, a controllable lighting system 4, a humidity regulator 5, a temperature control system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com