Anthracene oil hydrogenation method

An anthracene oil, hydrorefining technology, applied in the direction of hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of increasing the complexity of the hydrogenation system, increasing the cost, etc., to achieve long-term safe production, improve hydrogen The effect of partial pressure, harshness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

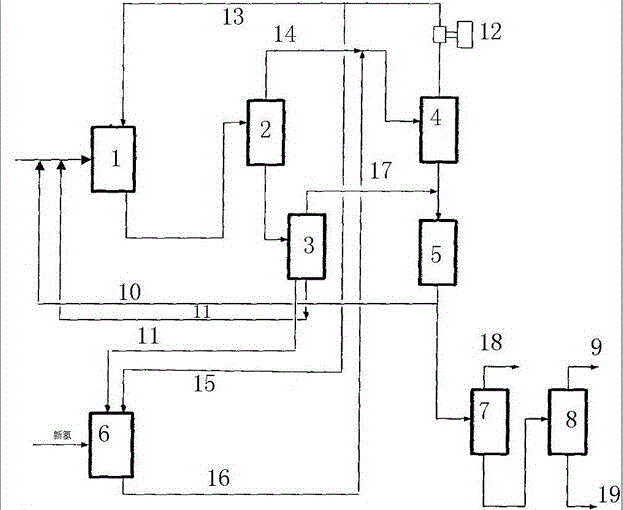

Method used

Image

Examples

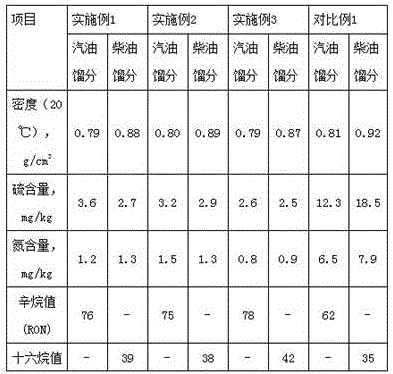

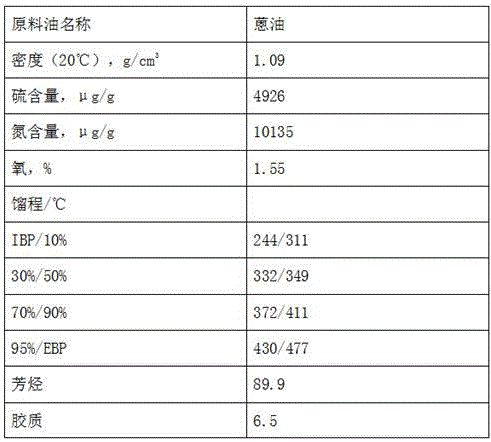

Embodiment 1

[0030] The weight ratio of the total weight of the hot low fraction oil and the cold low fraction oil recycled to the hydrotreating reactor in this embodiment and the raw material anthracene oil is 2:1; wherein the mass ratio of the hot low fraction oil and the cold low fraction oil is 1:1.5.

[0031] The conditions of hydrofining reaction are: reaction temperature is 405°C, pressure is 18MPa, volume ratio of hydrogen to oil is 1200:1 and space velocity is 0.3h -1 , the composition and properties of the hydrorefining catalyst are: molybdenum oxide 18wt%, nickel oxide 9wt%, and the carrier is alumina; wherein the catalyst pore volume is 0.40ml / g, and the specific surface area is 130m 2 / g, the catalyst dosage is 85 μg / g (the metal content in the catalyst required for every gram of hydrogenation raw material).

[0032] The total pressure of the hydrocracking reaction system is 14MPa, the reaction temperature is 280°C, and the reaction space velocity is 1.0h -1 , The standard v...

Embodiment 2

[0034] The weight ratio of the total weight of the heat low fraction oil and the cold low fraction oil recycled back to the hydrotreating reactor in this embodiment and the raw material anthracene oil is 3:1; wherein the mass ratio of the heat low fraction oil and the cold low fraction oil is 1:1.5.

[0035] The conditions of hydrofining reaction are: reaction temperature 410°C, pressure 19MPa, hydrogen-oil volume ratio 1600:1 and space velocity 0.6h -1 , the composition and properties of the hydrorefining catalyst are: molybdenum oxide 20wt%, nickel oxide 7wt%, and the carrier is alumina; wherein the catalyst has a pore volume of 0.60ml / g and a specific surface area of 145m 2 / g, the catalyst dosage is 95 μg / g (the metal content in the catalyst required for every gram of hydrogenation raw material).

[0036] Hydrocracking operating conditions, the total pressure of the hydrocracking reaction system is 13MPa, the reaction temperature is 275°C, and the reaction space velocit...

Embodiment 3

[0038] The weight ratio of the total weight of the heat low fraction oil and the cold low fraction oil recycled back to the hydrotreating reactor in this embodiment and the raw material anthracene oil is 3:1; wherein the mass ratio of the heat low fraction oil and the cold low fraction oil is 1:2.

[0039] The conditions of hydrofining reaction are: reaction temperature 405°C, pressure 19MPa, hydrogen-oil volume ratio 1500:1 and space velocity 0.5h -1 , the composition and properties of the hydrorefining catalyst are: molybdenum oxide 19wt%, nickel oxide 8wt%, and the carrier is alumina; wherein the catalyst has a pore volume of 0.50ml / g and a specific surface area of 138m 2 / g, the catalyst dosage is 90 μg / g (the metal content in the catalyst required per gram of hydrogenation raw material).

[0040] Hydrocracking operating conditions, the total pressure of the hydrocracking reaction system is 13MPa, the reaction temperature is 280°C, and the reaction space velocity is 0.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com