Preparation method of electronegative chitin nanofiber hydrogel and aerogel

A nanofiber and chitin technology is applied in the field of preparation of negatively charged chitin nanofiber hydrogels and aerogels, and achieves the effects of widening uses, simple and efficient operation, and simple and efficient gel preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 Preparation of chitin slurry

[0031] Take the crab shell raw material, wash and cut into pieces, the chopped raw material is alternately treated with 1 M sodium hydroxide and 1 M hydrochloric acid for 12 hours, and the protein and calcium in the crab shell are removed by three cycles of treatment, and then 0.5% NaClO 2 Solution bleaching removes pigment in crab shells. After bleaching, wash the bleached crab shells with distilled water until neutral, and store them in a refrigerator at 4°C. The bleached crab shell fragments are pulverized into a slurry by a pulverizer to obtain a purified chitin slurry.

Embodiment 2

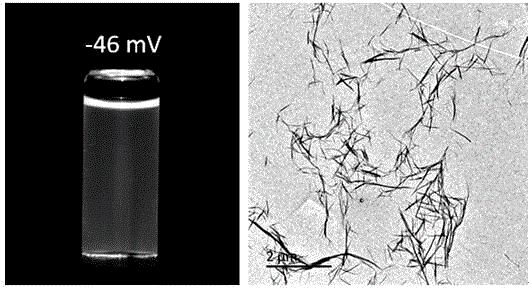

[0032] Example 2 Preparation of TEMPO oxidized chitin and negatively charged chitin nanofiber dispersion

[0033] Weigh 0.016g TEMPO, 0.1g NaBr, and 1g dry weight of purified chitin into a 200mL beaker and stir to dissolve. After the dispersion is uniform, add 5mL of chitin-containing 5% available chlorine NaClO solution to the system to start oxidation. Use a pH titration system to add 0.5M NaOH dropwise to the system at room temperature to maintain the pH at 10. When the system no longer consumes NaOH, add Stop the reaction with a few drops of ethanol, adjust the pH of the solution to 7 with 0.5M HCl, repeat centrifugal washing at 12,000 rpm for 5 min until neutral, remove the supernatant by pouring, and obtain the water-insoluble part, which is TEMPO oxidized chitin quality. The above-prepared TEMPO oxidized chitin was uniformly dispersed with distilled water at a solid-to-liquid ratio of 1:100, further homogenized and ultrasonically treated, and finally the supernatant wa...

Embodiment 3

[0034] Example 3 Preparation of Negatively Charged Chitin Nanofiber Dispersion Liquid Using Sodium Hydroxide as Weak Alkaline Medium

[0035] Weigh 0.016g TEMPO, 0.1g NaBr, and 1g dry weight of purified chitin into a 200mL beaker and stir to dissolve. After the dispersion is uniform, add 5 mL of chitin and 5% available chlorine NaClO solution to the system to start oxidation. Use a pH titration system to add 0.5M NaOH dropwise to the system at room temperature to maintain the pH at 10. When the system no longer consumes NaOH, add a few Drop ethanol to terminate the reaction, adjust the pH of the solution to 7 with 0.5M HCl, repeat centrifugal washing at 1200 for 5 minutes until neutral, and remove the supernatant by pouring to obtain the water-insoluble part. The obtained water-insoluble part is TEMPO oxidized chitin. Use distilled water to uniformly disperse the TEMPO oxidized chitin prepared above at a solid-to-liquid ratio of 1:100, adjust the pH of the solution to about 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com