Polyurethane elastomer antifreezing faucet and preparation method thereof

A polyurethane elastomer and faucet technology, applied in the field of polyurethane products, can solve problems such as waste of water resources, waste of faucets, cracking of faucets, etc., and achieve the effects of good water resistance, good expansion coefficient, and safe raw material components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

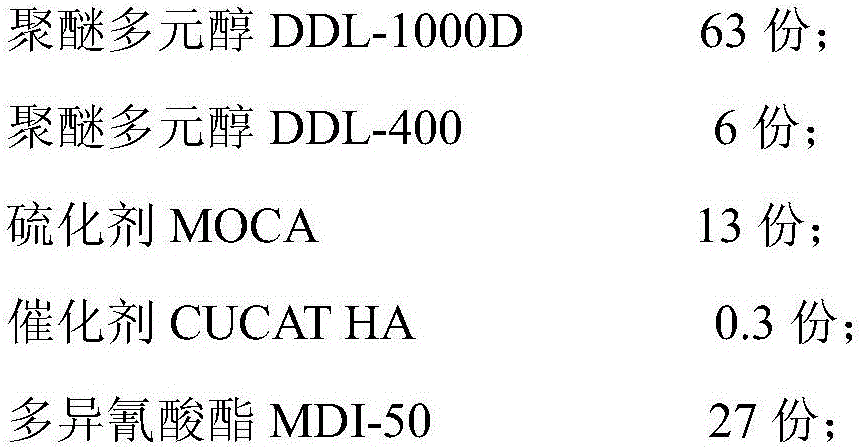

[0027] The polyurethane elastomer antifreeze faucet is composed of a copper valve core, an iron handle, a faucet housing and a fixing nut. The faucet housing and the fixing nut are made of the following raw materials in parts by weight:

[0028]

[0029] Its preparation method is as follows:

[0030] (1) Heat polyether polyol DDL-1000D at 110°C for 2 hours in vacuum dehydration, cool down to 25°C, add polyisocyanate MDI-50, heat up to 82°C and react for 2.5 hours, cool down to 45°C, add catalyst CUCAT HA and mix Evenly, to obtain a prepolymer, sealed for later use;

[0031] (2) Heat vulcanizing agent MOCA to 120°C and dissolve it in polyether polyol DDL-400, and mix evenly to obtain a mixture;

[0032] (3) Heating the prepolymer and the mixture to 80°C, mixing them evenly, pouring them into a mold, pressing the mold at 120°C for 0.25 hours, vulcanizing after demoulding, and obtaining the faucet shell and fixing nut;

Embodiment 2

[0042] The polyurethane elastomer antifreeze faucet is composed of a copper valve core, an iron handle, a faucet housing and a fixing nut. The faucet housing and the fixing nut are made of the following raw materials in parts by weight:

[0043]

[0044] Its preparation method is as follows:

[0045] (1) Heat polyether polyol DDL-1000D at 105°C for 1.5 hours in vacuum dehydration, cool down to 20°C, add polyisocyanate MDI-50, heat up to 80°C and react for 2 hours, cool down to 40°C, add catalyst CUCAT HA and mix Evenly, to obtain a prepolymer, sealed for later use;

[0046] (2) Heat vulcanizing agent MOCA to 110°C and dissolve it in polyether polyol DDL-400, and mix evenly to obtain a mixture;

[0047] (3) Heating the prepolymer and the mixture to 70°C, mixing them evenly and pouring them into a mold, pressing the mold at 110°C for 0.2 hours, vulcanizing after demoulding, to obtain the faucet shell and the fixing nut;

[0048] (4) Assemble the copper spool, iron handle, f...

Embodiment 3

[0057] The polyurethane elastomer antifreeze faucet is composed of a copper valve core, an iron handle, a faucet housing and a fixing nut. The faucet housing and the fixing nut are made of the following raw materials in parts by weight:

[0058]

[0059] Its preparation method is as follows:

[0060] (1) Heat polyether polyol DDL-1000D at 115°C for 2.5 hours in vacuum dehydration, cool down to 30°C, add polyisocyanate MDI-50, heat up to 85°C and react for 3 hours, cool down to 50°C, add catalyst CUCAT HA and mix Evenly, to obtain a prepolymer, sealed for later use;

[0061] (2) Heat vulcanizing agent MOCA to 130°C and dissolve it in polyether polyol DDL-400, and mix evenly to obtain a mixture;

[0062] (3) Heating the prepolymer and the mixture to 90°C, mixing them evenly, pouring them into a mold, pressing the mold at 130°C for 0.3 hours, vulcanizing after demoulding, and obtaining the faucet shell and fixing nut;

[0063] (4) Assemble the copper spool, iron handle, fauc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com