High strength fiber permeable concrete

A technology of permeable concrete and high-strength fiber, which is applied in the field of concrete to achieve good compressive strength and water permeability coefficient, maintain ecological balance, and achieve sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

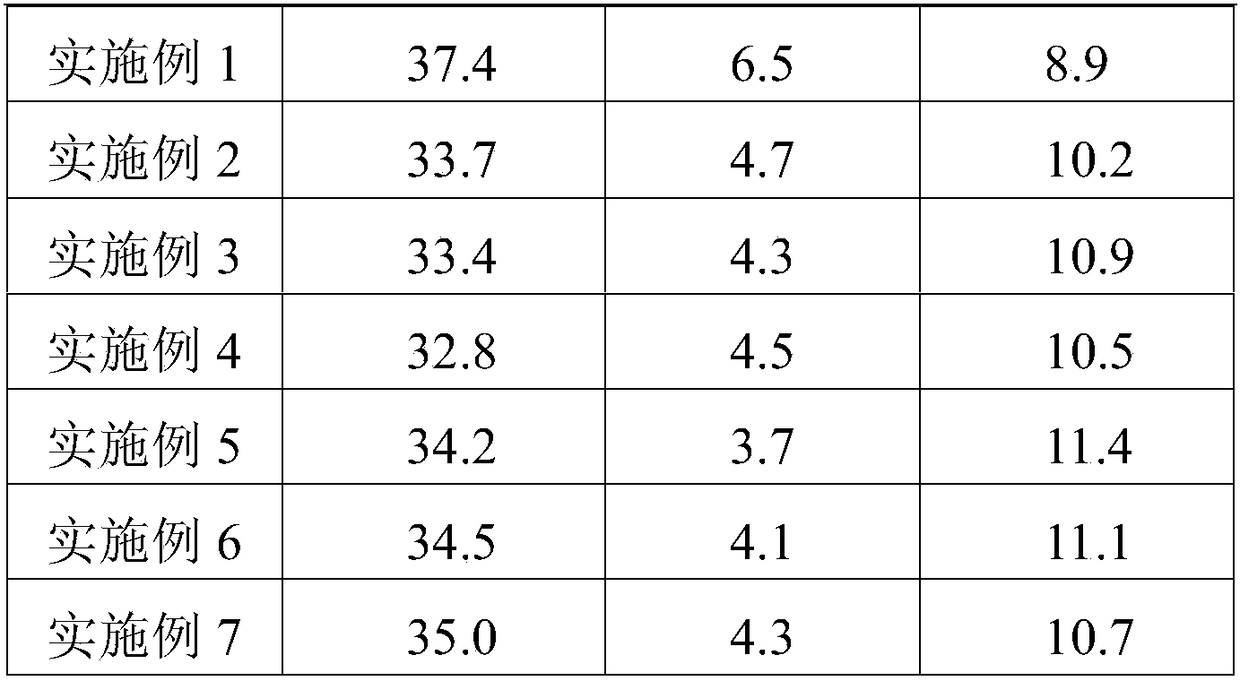

Examples

Embodiment 1

[0033] High-strength fiber permeable concrete raw materials (parts by weight): 100 parts of PO 42.5R cement, 500 parts of granite crushed stone, 8 parts of fly ash, 3 parts of polypropylene fiber, 5.4 parts of water reducing agent, 18 parts of nano composite filler, 33 parts of water .

[0034] The water reducing agent consists of sodium tris(1-methylethyl)naphthalene sulfonate, sodium 6-hydroxy-2-naphthalene sulfonate, and sodium 2,6-di-tert-butyl naphthalene sulfonate in a mass ratio of 1: 1:1 stir and mix evenly to obtain.

[0035] The nano composite filler is obtained by mixing and uniformly mixing titanium phosphate, copper tungstate and copper oxalate in a mass ratio of 1:1:1.

[0036] Preparation of high-strength fiber permeable concrete: add water reducing agent into water and mix evenly to obtain a mixed liquid; add PO 42.5R cement, granite crushed stone, polypropylene fiber, fly ash, and nano composite filler into a concrete mixer and mix evenly. Then add the mixed soluti...

Embodiment 2

[0038] It is basically the same as Example 1, except that the water reducing agent is mixed with sodium 6-hydroxy-2-naphthalene sulfonate and sodium 2,6-di-tert-butyl naphthalene sulfonate at a mass ratio of 1:1. Get it evenly. The high-strength fiber permeable concrete of Example 2 was obtained.

Embodiment 3

[0040] It is basically the same as Example 1, except that the water reducing agent is composed of sodium tris(1-methylethyl)naphthalene sulfonate and sodium 2,6-di-tert-butyl naphthalene sulfonate in a mass ratio of 1: 1 Stir and mix evenly to obtain. The high-strength fiber permeable concrete of Example 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com