Balance type rear wheel drive forklift automatically adjusting center of gravity

An automatic adjustment, rear wheel drive technology, applied in the direction of the lifting device, etc., can solve the problems of ineffective guarantee of safety, easy back flip, easy front flip and rollover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

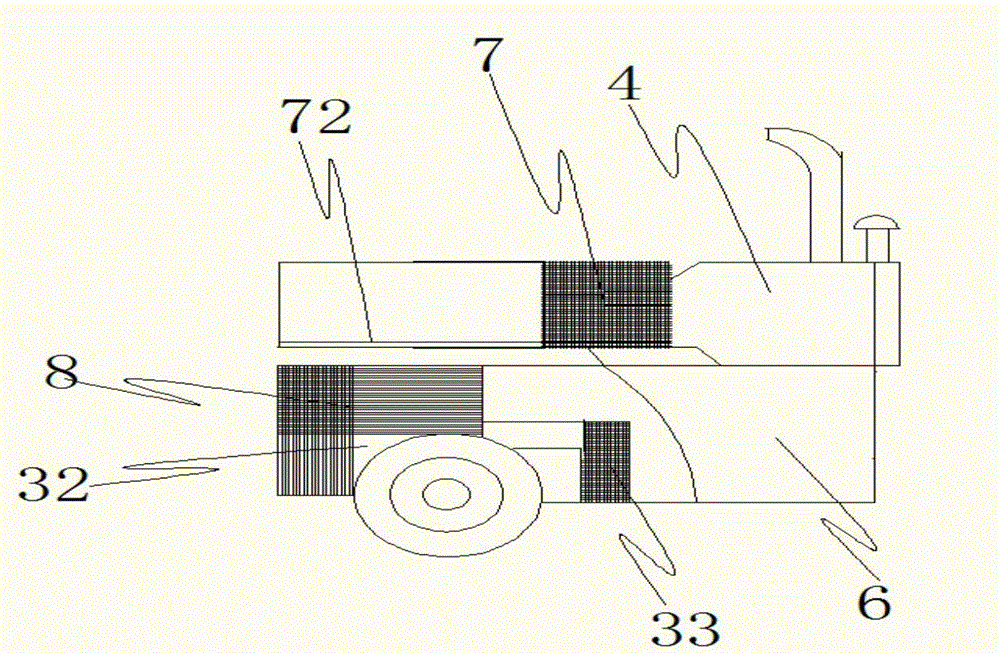

[0026] like figure 1 As shown, a balanced rear wheel drive forklift truck with automatic center of gravity adjustment of the present invention includes a cab 1, a fork frame 2 with a fork attachment 22, a front frame 31, a rear frame 32, an engine 4, Torque converter 5, fuel tank 6, movable upper balance weight 7, lower balance weight 8, center of gravity adjustment control center 9.

[0027] Wherein, the front vehicle frame 31 and the rear vehicle frame 32 are hinged by the upper and lower hinge pins 33, and the hinge point is arranged between the front and rear wheels and is close to the rear wheels; The torque converter 5, the fuel tank 6, the movable upper balance weight 7 and the front wheels are arranged on the front frame 31, and the lower balance weight 8 and the rear wheels are arranged on the rear frame 32;

[0028] A gravity sensor 21 is installed on the joint between the fork attachment 22 and the fork frame 2, the gravity sensor 21 sends a signal to the center of...

no. 2 example

[0038] The present invention is a balanced rear-wheel drive forklift truck with automatic center of gravity adjustment. The fork frame 2 on which the fork attachment 22 is installed is a bucket assembly attachment.

[0039] The parts not described in this embodiment are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com