Multifunctional adhesive tape automatic pasting and cutting machine

An automatic pasting and cutting machine technology, applied in the direction of external support, transportation packaging, packaging, etc., can solve the problems of low degree of automation, slow response speed, single function, etc., and achieve paste quality assurance, continuous tape pasting, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

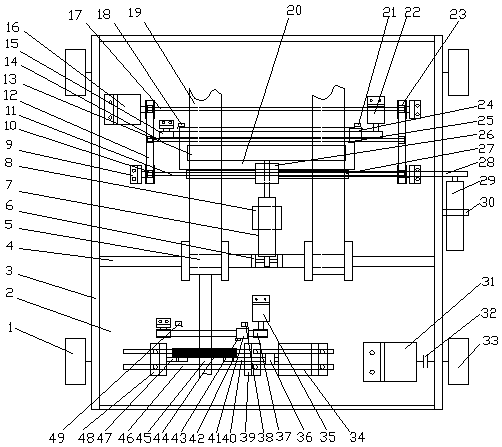

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Such as Figure 1-3 As shown, three auxiliary wheels 1, a base plate 2, four side plates 3 and a driving wheel 33 are connected to form a vehicle frame, and the driving wheel 33 is connected to a mobile motor 31 located on the base plate 2 through a coupling 32 to form a mobile vehicle frame. A tape flat paste cutter and a tape roll paste cutter are installed on the mobile frame to form a multifunctional tape automatic pasting and cutting machine.

[0016] Wherein, the adhesive tape flat sticking cutter is composed of two parts, a flat sticking mechanism and a flat sticking and cutting mechanism; the flat sticking mechanism includes a telescopic support rod 4, an adhesive tape reel 5, a tailstock support 6, a cylinder cylinder 7, a base support 8. Toothed belt wheel bracket 9, cross brace fixing part 10, No. 1 cross brace 11, No. 1 too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com