AC (alternating current) contactor automatic labeler

An AC contactor, automatic technology, used in labeling, labeling machines, labels, etc., can solve the problems of low work efficiency and high labor intensity, and achieve the effect of high work efficiency, labor saving, and firm labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

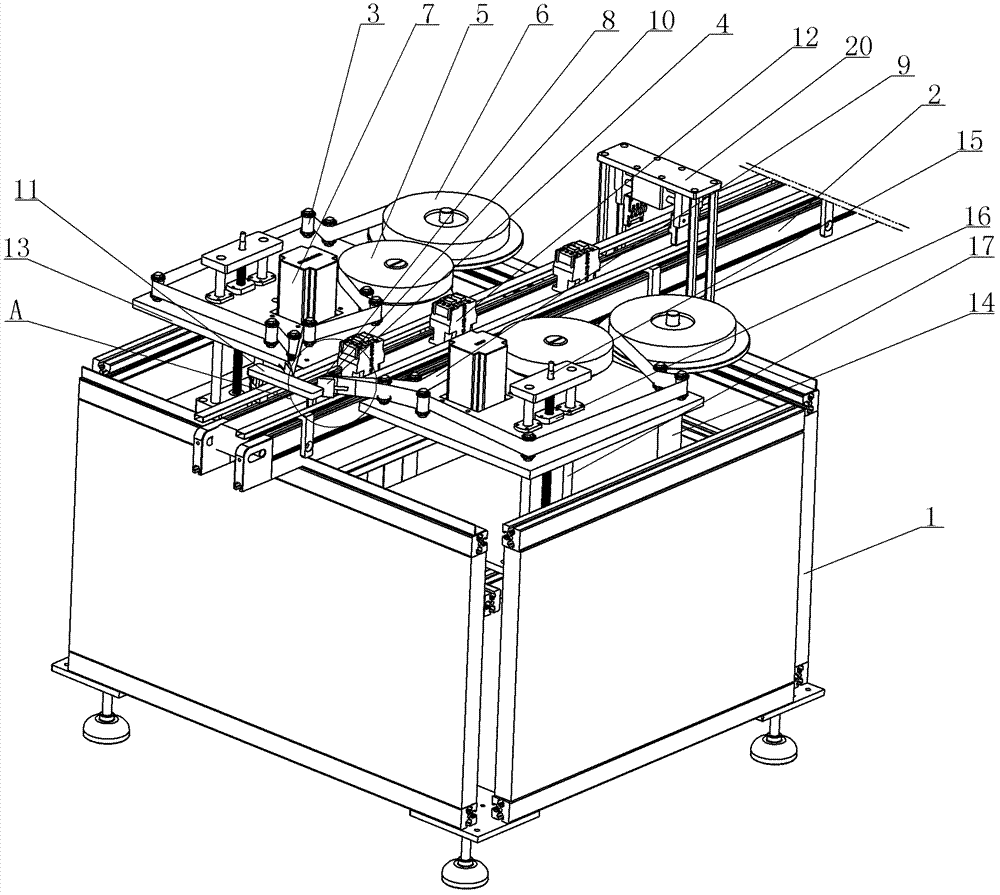

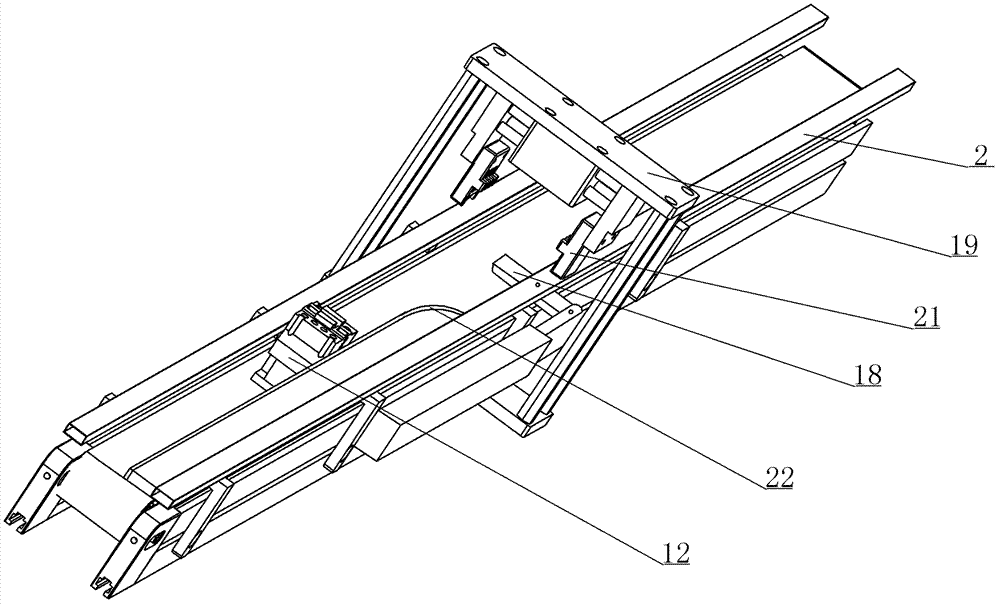

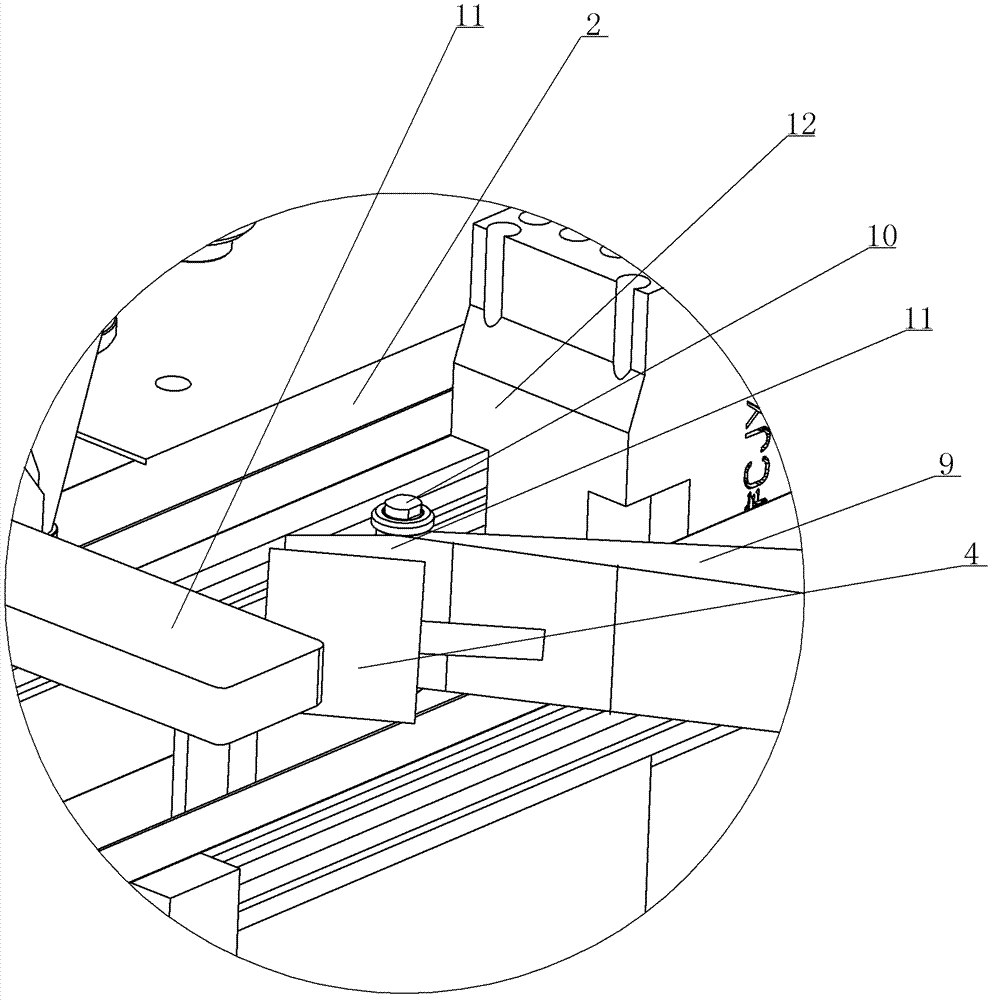

[0017] Depend on figure 1 combine figure 2 , image 3 As shown, an automatic labeling device for an AC contactor includes a frame 1 and a belt conveyor 2, the belt conveyor 2 passes through the frame 1, and at least one side of the belt conveyor 2 is equipped with a base belt retractable device, a guide wheel 3 and The pressing device 4, the base tape retracting device is composed of a take-up roller 5, a storage roller 6 and a stepping motor 7, the storage roller 6 is driven by the stepping motor 7, and the storage roller 6 is on the plate Roll the base tape 9 pasted with the label 8, and the label 8 is continuously pasted on the smooth surface of the base tape 9 by self-adhesive, and a label separation wheel 10 is provided on the conveying path frame of the belt conveyor 2, and one end of the base tape 9 passes through the guide wheel 3, the label The separation wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com