Negative pressure cleaning system for the cooler of the vacuum system of the auxiliary extruder of the film production line

A vacuum system and negative pressure cleaning technology, applied in the field of negative pressure cleaning system, can solve the problems of too many human resources for machine repair, affecting production efficiency, increasing downtime, etc., to reduce manual cleaning labor, increase cooling work area, and improve cooling. efficacy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

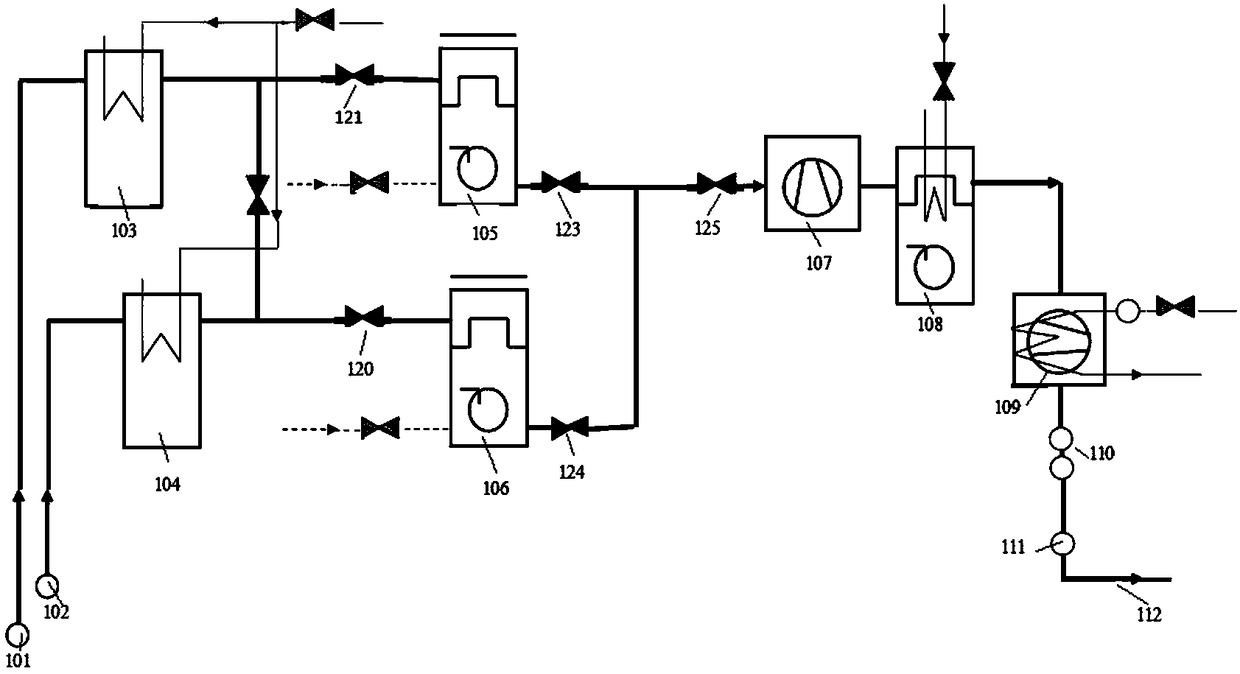

[0022] refer to figure 1 The working principle diagram of the vacuum system of the existing PET film auxiliary extruder is shown, and the working process is as follows: at a working temperature of 270°C, ethylene terephthalate is volatilized from the melted material, and small molecules and water The mixed gas with steam as the main component is cooled by vacuum cover 1 101 and vacuum cover 2 102 through the active heat preservation connecting pipes that are electrically heated to 160°C, and then enters cooler 1 103 and cooler 2 104 for cooling. The active insulation connecting pipe heated to 120°C and the solenoid valve 121 and solenoid valve 120 respectively enter the filter one 105 and the second filter 106, the cross-sectional area of the filter channel increases suddenly, the flow velocity slows down, and the filter has no heat preservation measures. The mixed gas is naturally cooled, and the temperature drops further, the small molecules in the mixed gas condense into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com