Guide ejecting pressing type plate cutting device

A cutting device, a technology for plates, applied in metal processing, removal of smoke and dust, cleaning methods and utensils, etc., can solve problems such as plate tearing and plate cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0031] In the present invention, in the absence of a contrary statement, the orientation words included in the term, such as "upper, lower, inner, outer, top, bottom", etc., only represent the orientation of the term in the normal use state, or for the purpose of A common term understood by those skilled in the art, and should not be considered as a limitation of the term.

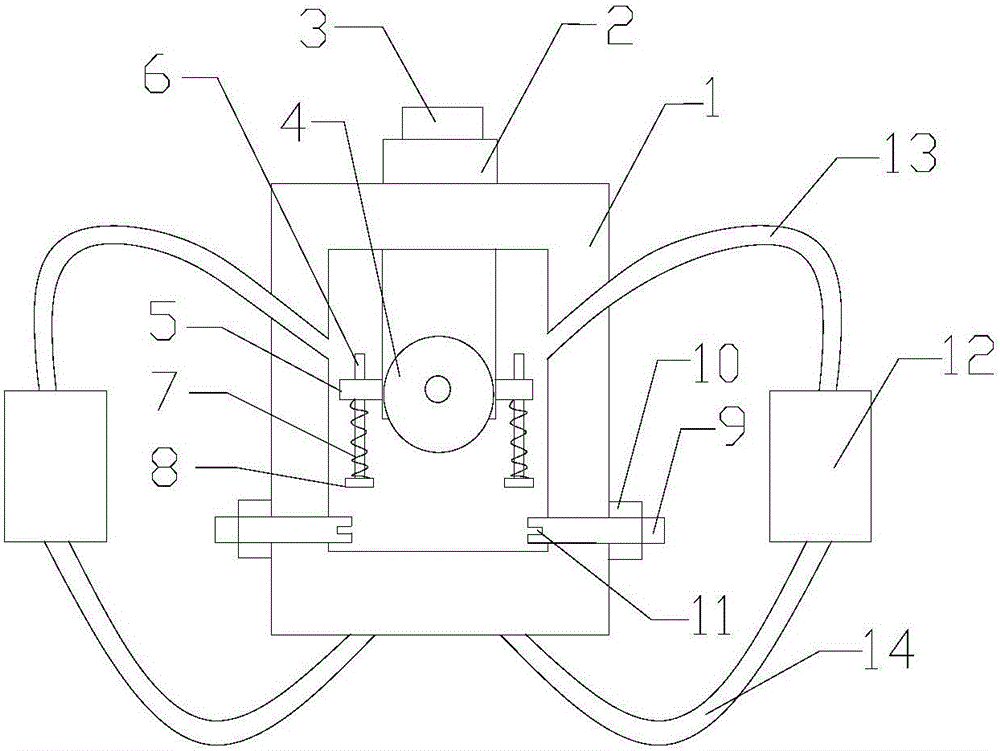

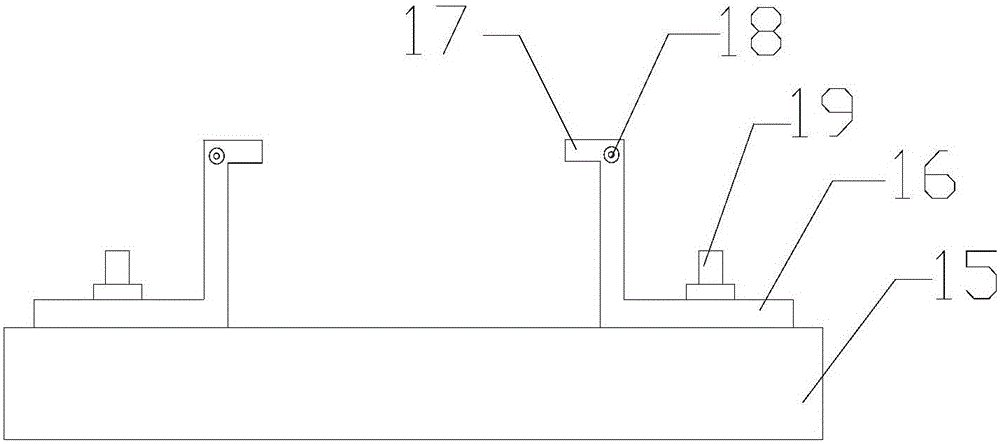

[0032] The invention provides a guiding and pressing plate cutting device, such as figure 1 As shown, it includes a main body 1, a cutting cavity is formed in the main body 1 along the conveying direction of the plate, the bottom of the cutting cavity is formed with a cutting groove downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com