A kind of powder forming device and forming method thereof

A molding device and powder technology, which is applied in the field of powder molding, can solve problems such as complex molding methods and long production cycles, and achieve the effects of simple processing procedures, rapid prototyping, and improved orientation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

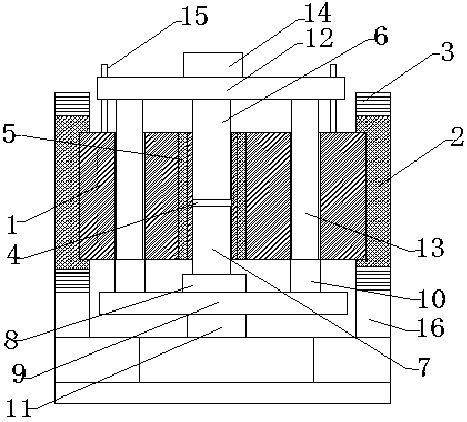

[0020] Such as figure 1 A powder molding device shown includes a molding die 1, and a pair of yokes 2 engaged on the outside of the molding die; and a coil 3 wound on the outside of the yoke; and a cavity 4 provided in the middle of the molding die; and The straight yoke 5 vertically embedded on the outside of the mold cavity; the upper mold 6 and the lower mold 7 movable embedded in the upper and lower sides of the mold cavity; and the vibration mechanism 8 installed in cooperation with the bottom of the lower mold; the vibration mechanism 8 Installed on the top plate 9; a hollow slide bar 10 is also installed on the top plate 9; the hollow slide bar 10 is movably fitted with the molding die 1; a lower hydraulic installation mechanism 11 is arranged below the top plate 9; the upper mold 6. A pressing plate 12 is installed on the top; stamping rods 13 are installed on both sides of the pressing plate 12;

[0021] The top of the molding die 1 is provided with a guide rod 15 ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com