Method for preparing multi-channel hollow fiber nano-filtration membranes

A multi-channel, nanofiltration membrane technology, applied in the field of membrane separation, can solve the problems of industrial scale application limitations, low toughness and strength of hollow fiber nanofiltration membranes, and achieve continuous large-scale production, high strength, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

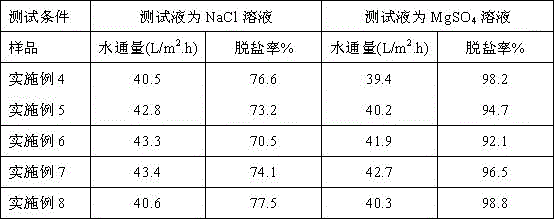

Examples

Embodiment 1

[0015] Add polyethersulfone, dimethylacetamide, and polyethylene glycol into the reactor at a mass ratio of 15%:40%:45% and stir for 24 hours to form a uniform and stable casting solution. After vacuum degassing for 12 hours, drive at 0.1MPa It is sprayed out through a multi-channel hollow fiber mold under pressure, the flow rate of the core liquid water is 10ml / min, and the air gap is 0cm, soaked in the water of the external coagulation bath for 24 hours, and dried at 50°C after taking it out.

Embodiment 2

[0017] Add polyethersulfone, dimethylacetamide, and polyethylene glycol into the reactor at a mass ratio of 15%:40%:45% and stir for 24 hours to form a uniform and stable casting solution. After vacuum degassing for 12 hours, drive at 0.1MPa It is sprayed out through a multi-channel hollow fiber mold under pressure, the flow rate of the core liquid water is 10ml / min, and the air gap is 5cm, soaked in the water of the external coagulation bath for 24 hours, and dried at 50°C after taking it out.

Embodiment 3

[0019] Add polyethersulfone, dimethylacetamide, and polyethylene glycol into the reactor at a mass ratio of 15%:40%:45% and stir for 24 hours to form a uniform and stable casting solution. After vacuum degassing for 12 hours, drive at 0.1MPa It is sprayed out through a multi-channel hollow fiber mold under pressure, the flow rate of the core liquid water is 10ml / min, and the air gap is 10cm, soaked in the water of the external coagulation bath for 24 hours, and dried at 50°C after taking it out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com