Bag type dust collector

A bag filter and bag technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of bag breakage, high vibration and noise, and poor sealing of the bag filter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

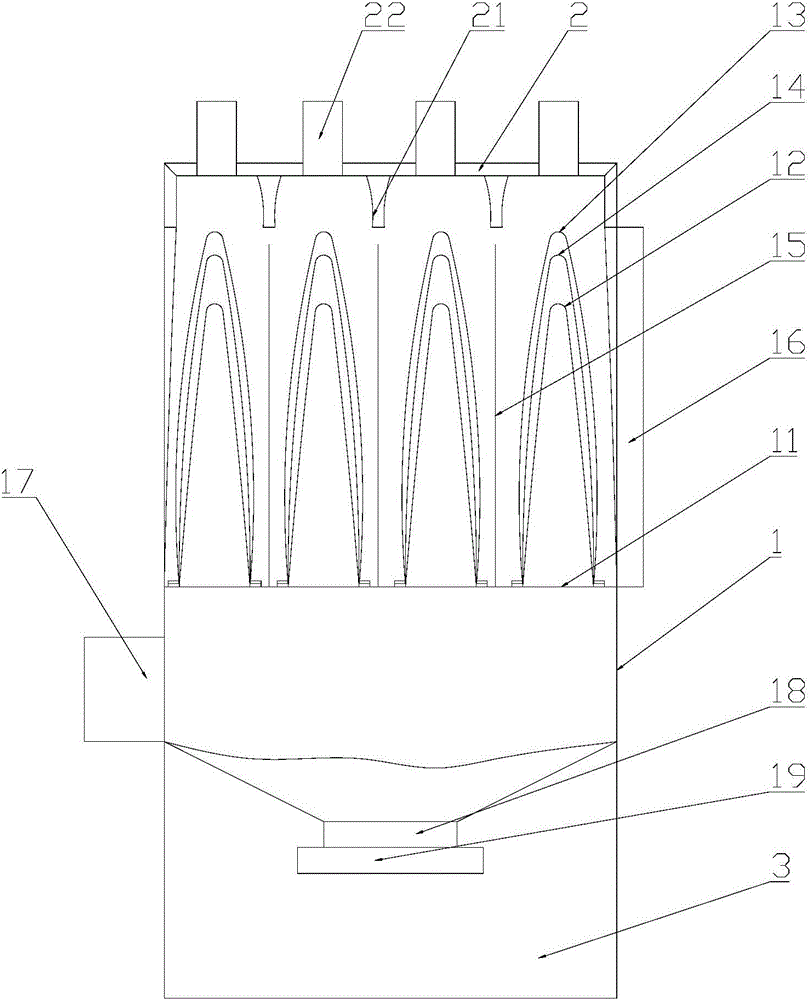

[0027] like figure 1 As shown, a bag filter includes a chassis 1, a cover body 2 and a frame 3, the chassis 1 is arranged on the frame 3, the cover body 2 is arranged on the chassis 1, and the middle part of the chassis 1 is provided with a positioning groove, and the positioning groove A filter partition 11 is provided inside, and a through hole is provided on the filter partition 11, and a first metal mesh 12 corresponding to the through hole and whose radius gradually decreases from bottom to top is provided on the filter partition 11. The net 12 is provided with a second metal net 13, and a cloth bag 14 is arranged between the first metal net 12 and the second metal net 13, so that the dust-removing surface of the cloth bag 14 faces the ground, and the dust on the cloth bag 14 is subjected to gravity and accumulates in the cleaning area. On the ash port 18, the amount of dust accumulated on the cloth bag 14 is reduced, and the cloth bag 14 is set between the first metal me...

Embodiment 2

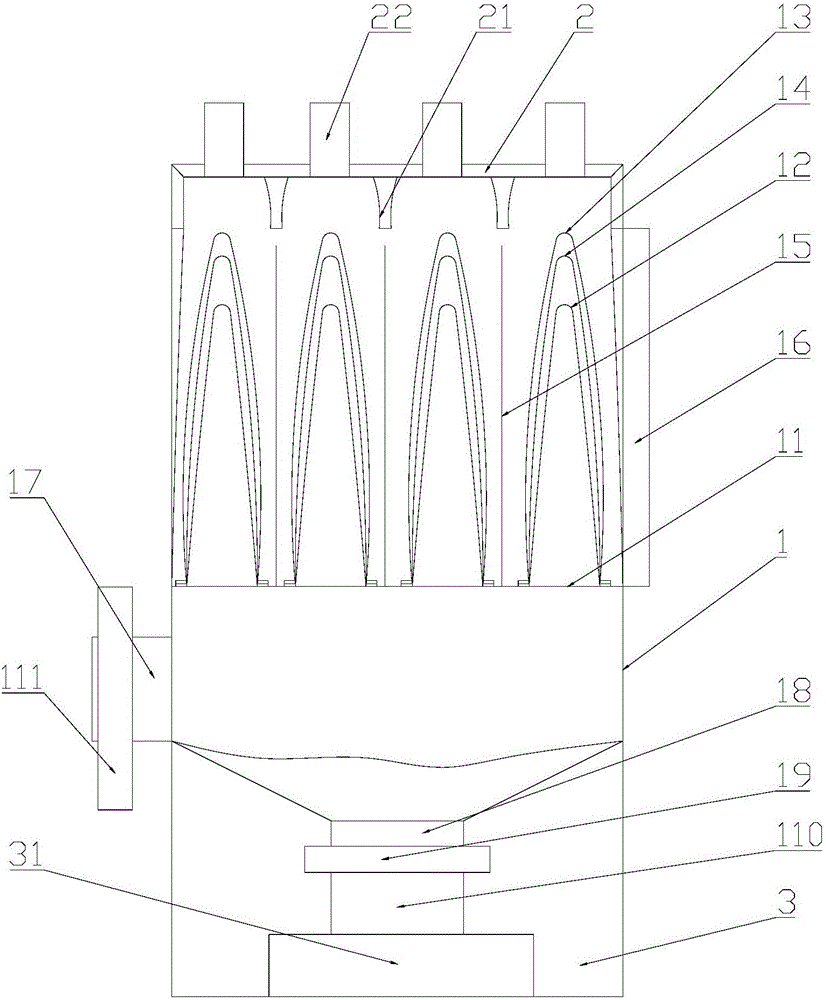

[0038] like figure 2 As shown, a bag dust collector, compared with Embodiment 1, differs in that the lower part of the electric valve 19 is connected with a dust basket 110, and the frame 3 is provided with an exhaust device corresponding to the dust basket 110 31. There is a manual sealing valve 111 on the intake pipe 17. When cleaning the dust inside the bag filter, the manual sealing valve 111 seals the intake pipe 17, opens the electric valve 19 and the exhaust device 31, and collects the dust in the dust basket 110 Among them, while reducing the labor intensity of the workers, the part of the dust accumulated in the cloth bag 14 is also cleaned, and the rest are the same as in Embodiment 1, and are not particularly limited here, and all belong to the protection scope of the present invention. Its production process is also the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com