Mild liquid soap and preparation method thereof

A kind of hand sanitizer, mild technology, applied in the field of non-irritating mild hand sanitizer and its preparation, can solve the problems of high production cost, wrinkled fingers, human skin damage, etc., and achieve simple manufacturing process, strong cleaning ability, pH Moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

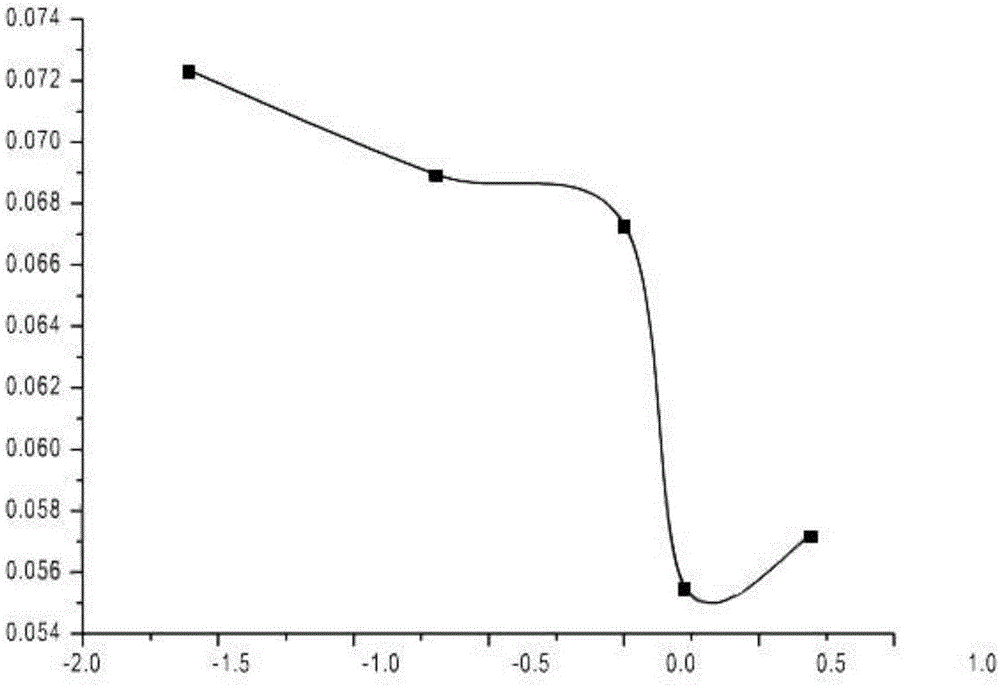

Image

Examples

Embodiment 1

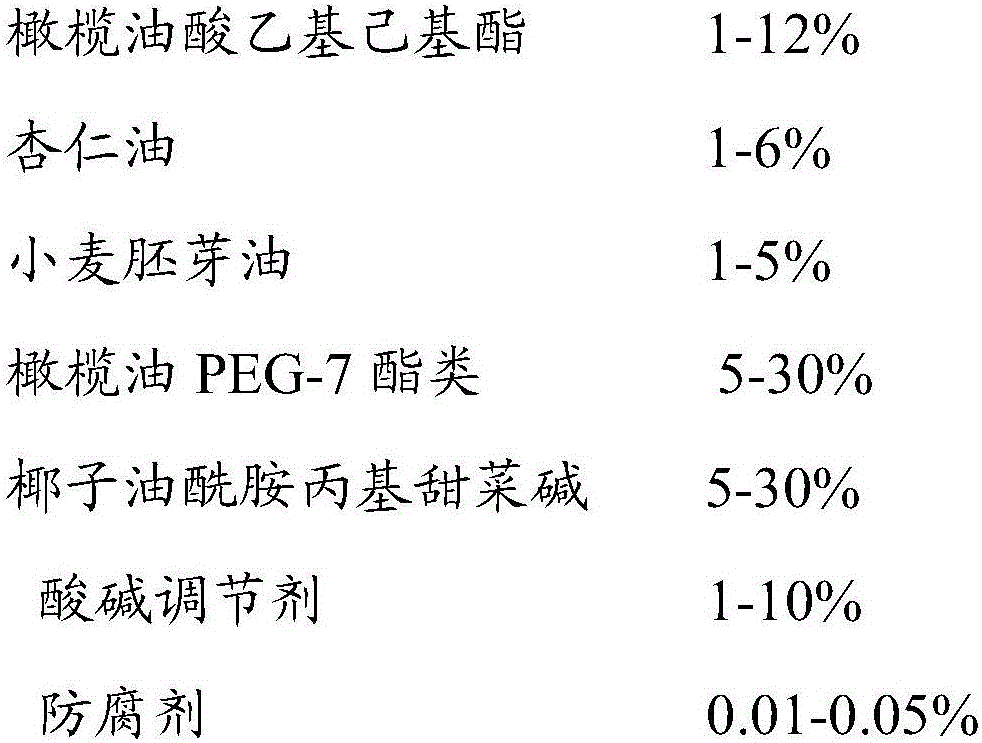

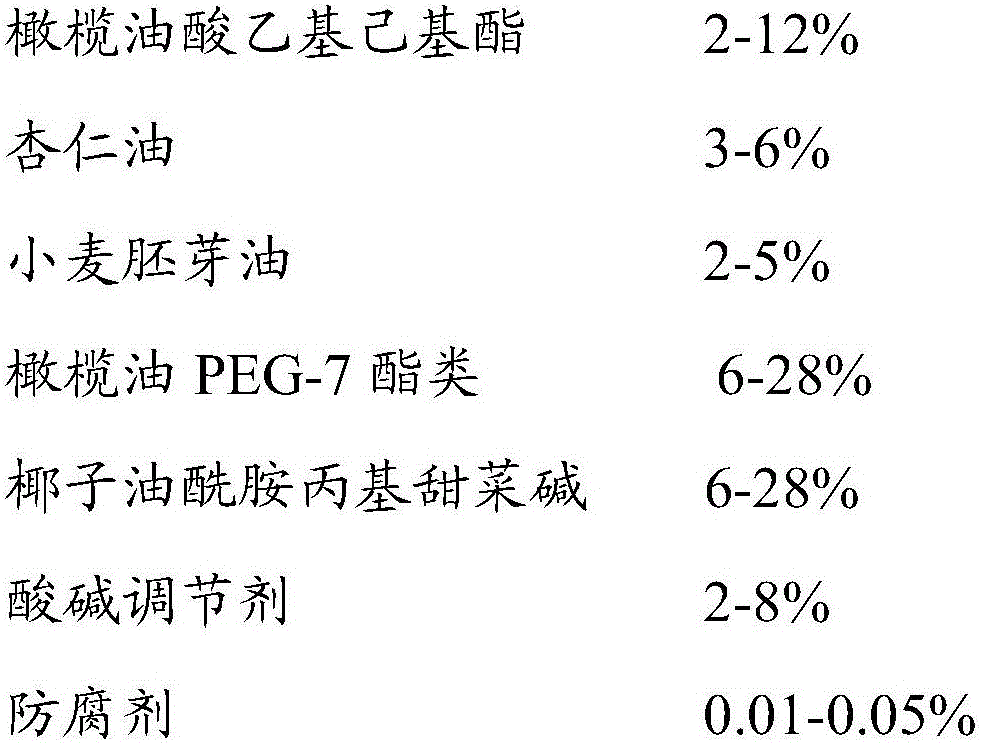

[0046] 1. Raw material ratio

[0047] serial number

raw material name

parts by weight

1

Ethylhexyl Olivate

3

2

2

3

Wheat germ oil

1

4

Olive Oil PEG-7 Esters

5

5

Cocoamidopropyl Betaine

5

6

Sodium citrate

0.5

7

0.5

8

0.01

9

Potassium sorbate

0.075

10

water

8.7915

[0048] 2. Preparation process

[0049]S11: At 80°C, mix ethylhexyl olive oil, almond oil, wheat germ oil, olive oil PEG-7 esters, and cocamidopropyl betaine evenly, and heat for 30 minutes to obtain emulsion A1;

[0050] S12: Add sodium citrate and citric acid into water at 80° C., mix evenly, and heat for 10 minutes to obtain emulsion B1.

[0051] S13: Mix the emulsion A1 and the emulsion B1, stir at a stirring speed of 300rpm for 15min, then cool down to 45°C, add sorbic acid and potassium sorbate, stir at a stirring speed of 200r...

Embodiment 2

[0060] 1. Raw material ratio

[0061]

[0062]

[0063] 2. Preparation process

[0064] S21: At 85°C, ethylhexyl olive oil, dodecyl olive oil, hydrogenated olive oil, olive oil PEG-7 esters, ceteareth-6 olive oil Ester, sorbitan olivate, and PEG-4 olivate base were mixed evenly, and heated for 30 minutes to obtain emulsion A2;

[0065] S22: Add sodium sulfate, sodium chloride, citric acid, and sodium citrate into water at 85° C., mix evenly, and heat for 5 minutes to obtain emulsion B2.

[0066] S23: Mix the emulsion A2 and the emulsion B2, stir at a stirring speed of 350rpm for 10min, then cool down to 45°C and add methylisothiazolinone, DMDM hydantoin, phenoxyethanol, ethylhexyl Glycerin, stirred at a stirring speed of 250rpm for 8min to obtain mild hand sanitizer.

[0067] The production process of this embodiment is basically the same as that of Example 1, and the sensory indicators, physical and chemical indicators, and hygienic indicators of the obtained produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com