Intelligent helmet and manufacturing method thereof

A technology of smart helmets and manufacturing methods, applied in the direction of helmets, helmet caps, hat products, etc., to achieve the effects of reducing product weight, avoiding detachment, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

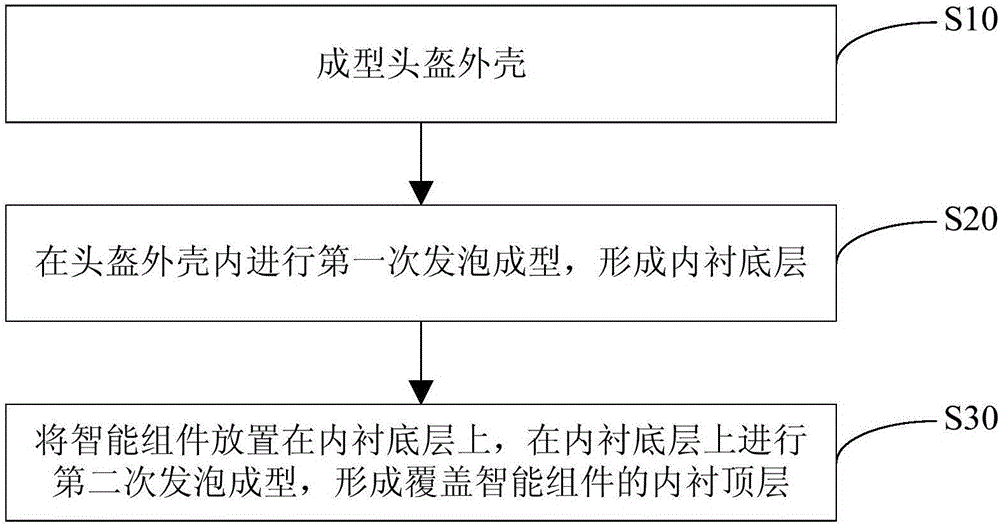

[0038] This embodiment provides a method for manufacturing a smart helmet, specifically as figure 1 As shown, the manufacturing method includes the following steps:

[0039] S10: Molded helmet shell.

[0040] That is, the PC sheet is molded into the helmet shell of the required shape by blistering, and the required helmet shell can also be selected by injection molding according to the needs. The specific methods of blistering or injection molding are all prior art, and the processing technology thereof will not be described in this embodiment.

[0041] S20: Carry out the first foam molding in the helmet shell to form the inner substrate layer.

[0042] Specifically, the helmet shell is put into a foaming mold adapted to its shape, and then foamed in the foaming mold to form an inner substrate layer located in the helmet shell. In this embodiment, the in-mold steam pressure of the above-mentioned foam molding is 0.8-1.5 standard atmospheric pressure, and the in-mold steam t...

Embodiment 2

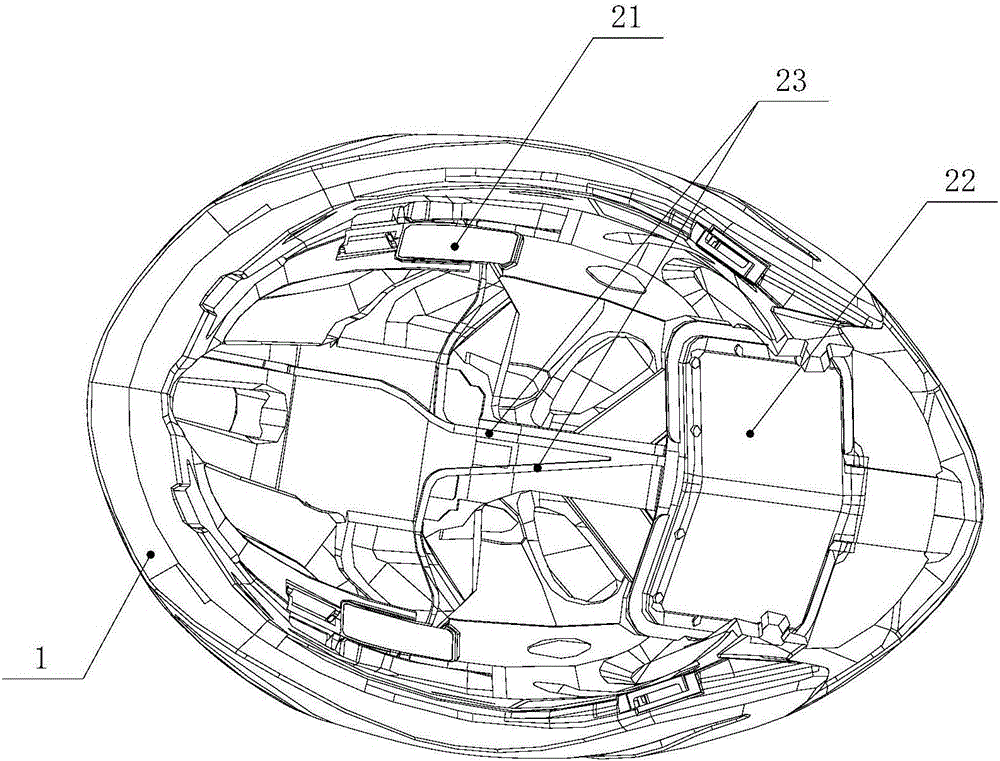

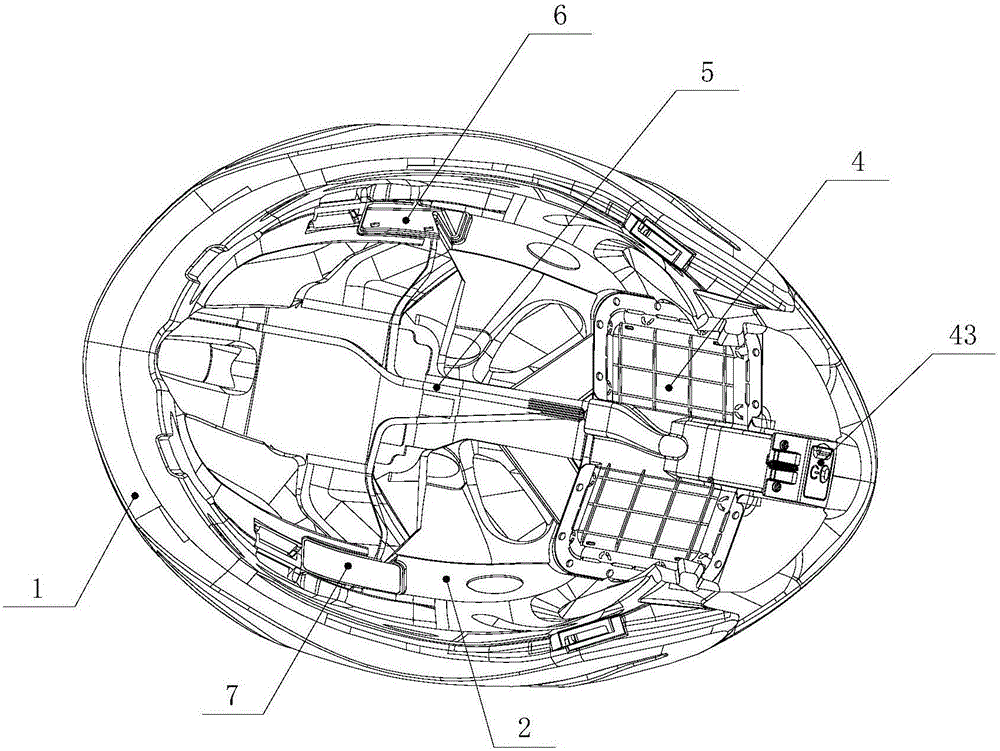

[0063] This embodiment provides a smart helmet, which is manufactured using the manufacturing method described in Embodiment 1, specifically, as Figure 2-4 As shown, it includes a helmet shell 1, an inner substrate layer 2 and an inner lining top layer 3 that are formed in the helmet outer shell 1 and arranged in sequence from the inside to the outside through foam molding, and the inner substrate layer 2 and the inner lining top layer 3 are integrally formed There are smart components. By integrally molding the smart components with the inner base layer 2 and the inner liner top layer 3, the user's comfort when using the smart helmet can be improved, and the use of the wire frame is eliminated, thereby reducing the manufacturing cost. In this embodiment, the inner substrate layer 2 and the inner lining top layer 3 are respectively molded through two times of foam molding. The specific molding process can refer to the manufacturing method of the smart helmet described in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com