Lead-acid battery automatic back cover powder filling system

A lead-acid battery, fully automatic technology, applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of human body hazards, flying lead powder, easy damage, etc., to facilitate maintenance, ensure life, and reduce noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

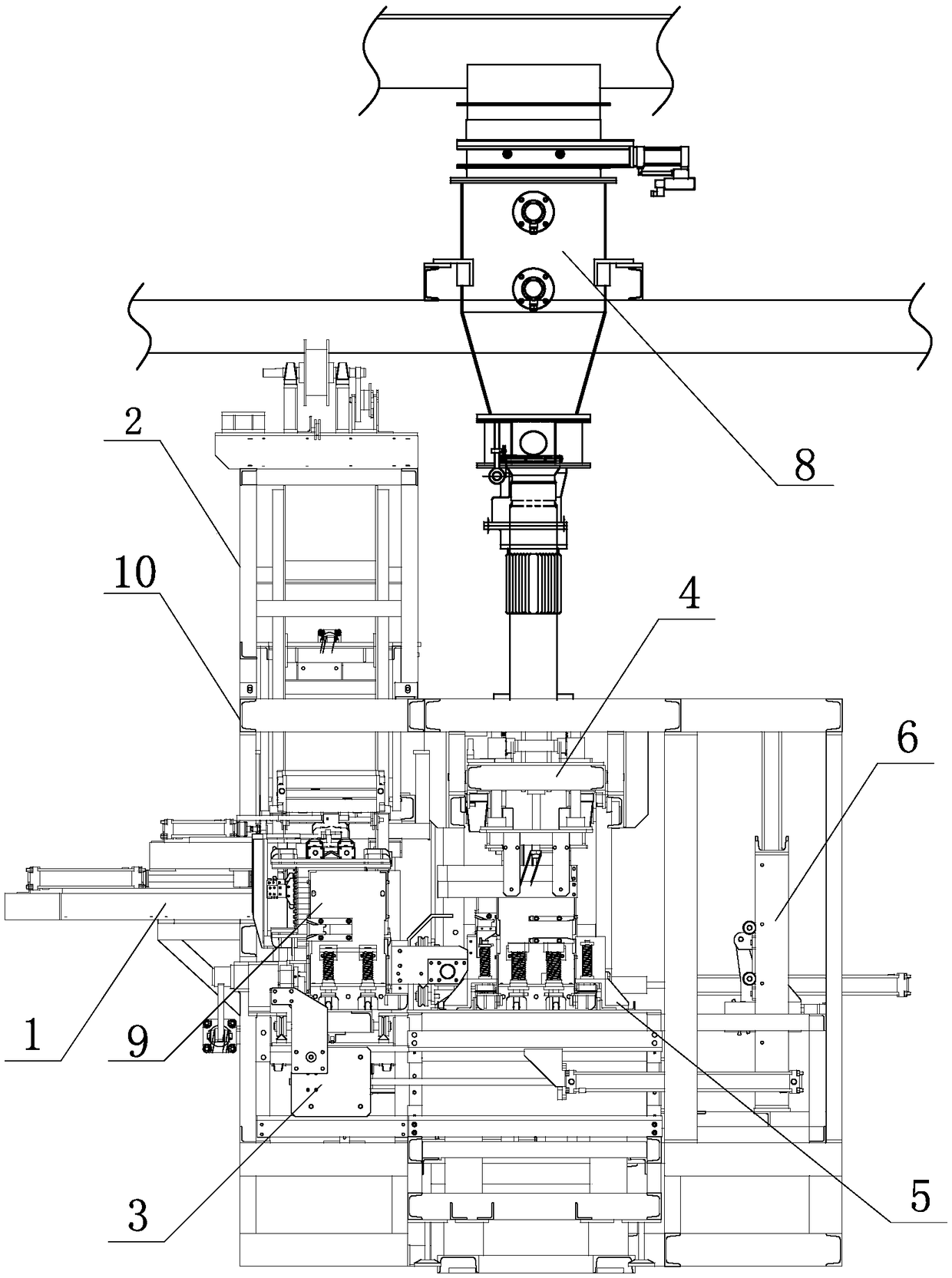

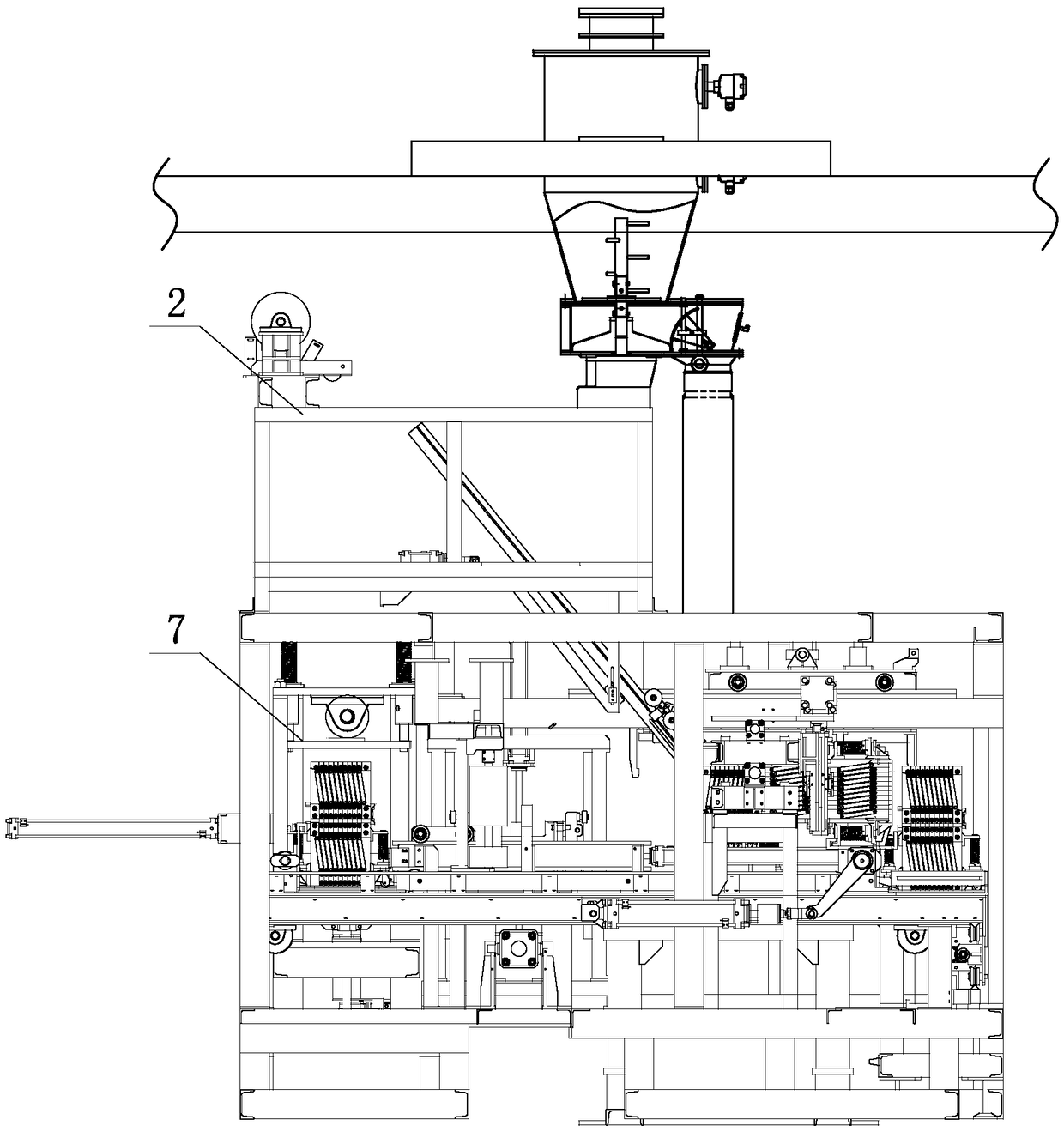

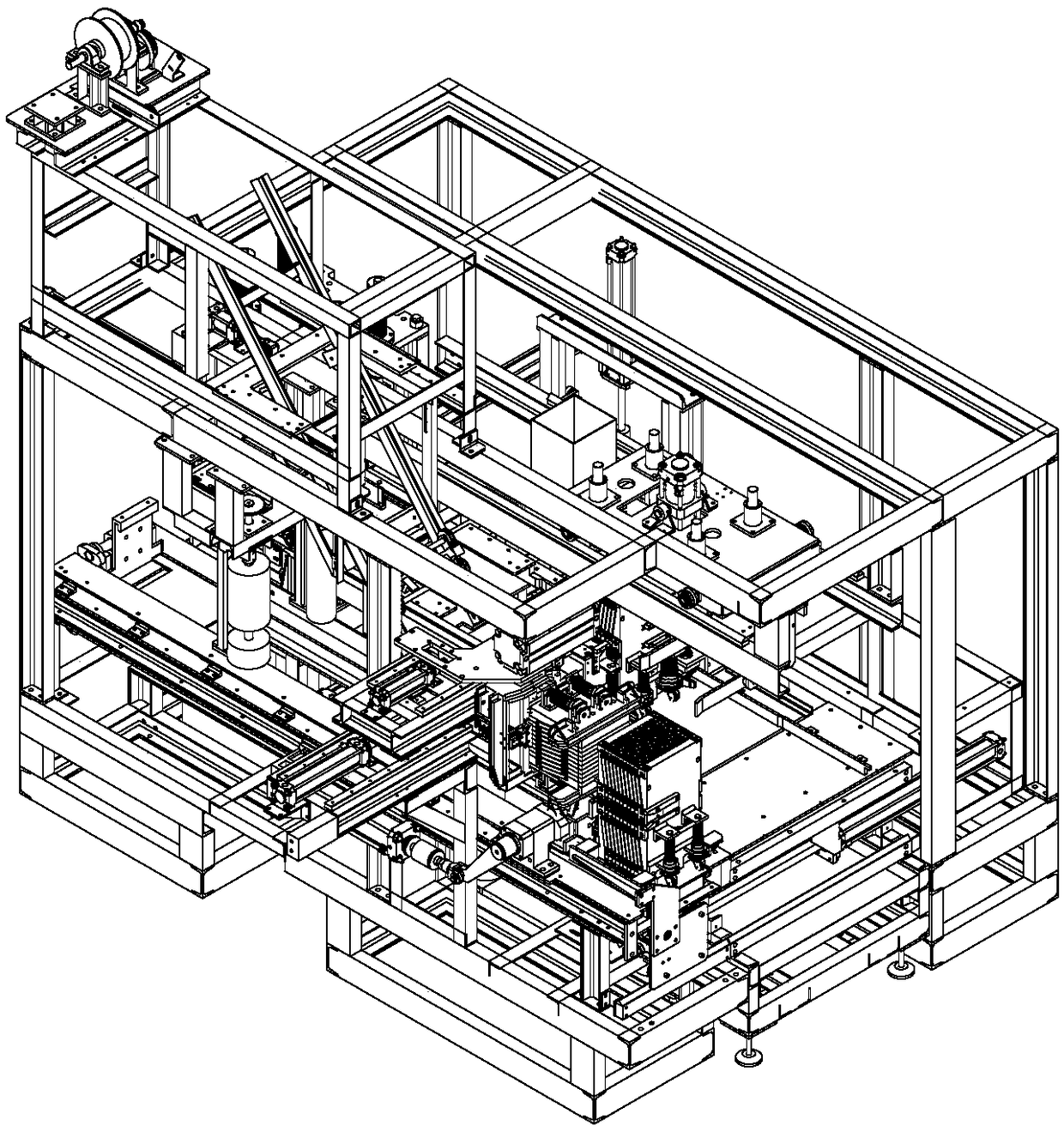

[0049] Such as Figure 1-Figure 3As shown, the lead-acid battery automatic back cover powder filling system includes a complete machine frame 10, which is provided with a tooling locking device 1, a tooling opening device 2, a mobile stand device 3, a tooling transfer device 4, and a vibration platform Device 5, turning powder brushing device 6, automatic bottom sealing device 7 and quantitative powder lowering device 8;

[0050] Such as Figure 4 , Figure 5 As shown, the tooling locking device 1 includes a mounting bracket 1-1, the mounting bracket 1-1 is provided with a lower mounting frame 1-2, and the lower mounting frame 1-2 is provided with a glideway and a first push cylinder 1-3, The upper mounting frame 1-4 is installed on the glide path, the piston rod of the first push cylinder 1-3 is connected to the upper mounting frame 1-4, and one end of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com