Vacuum dyeing method for ultrathin sections of electron microscope

A technology of ultra-thin sectioning and staining, which is applied in the preparation of test samples, instruments, scanning probe technology, etc., to achieve the effect of clean slices, good staining effect and short staining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

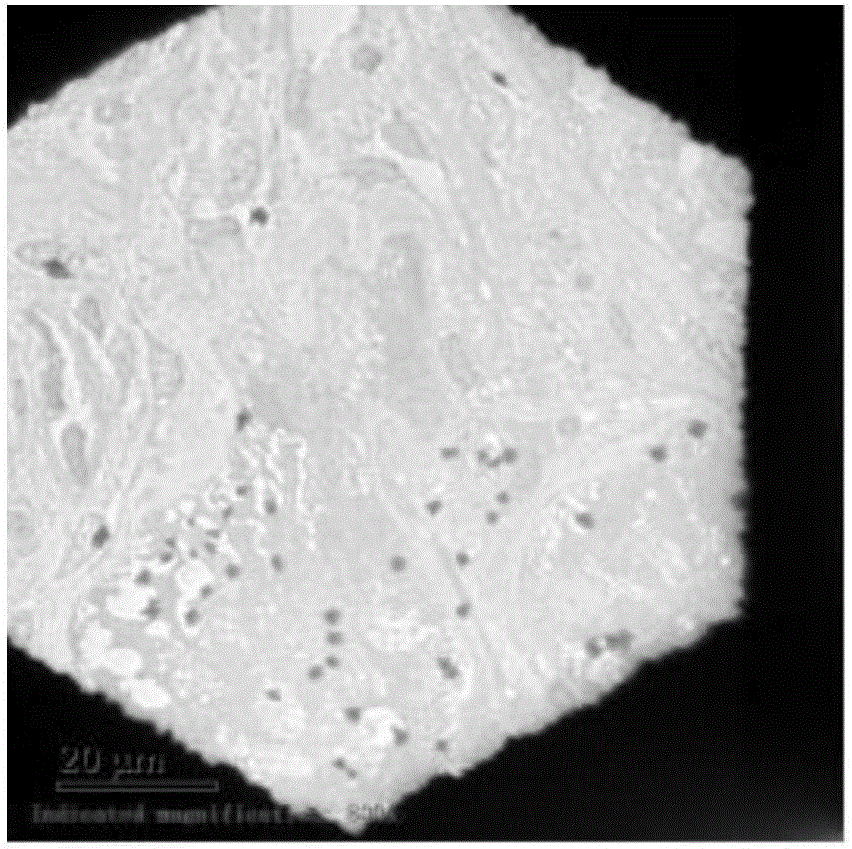

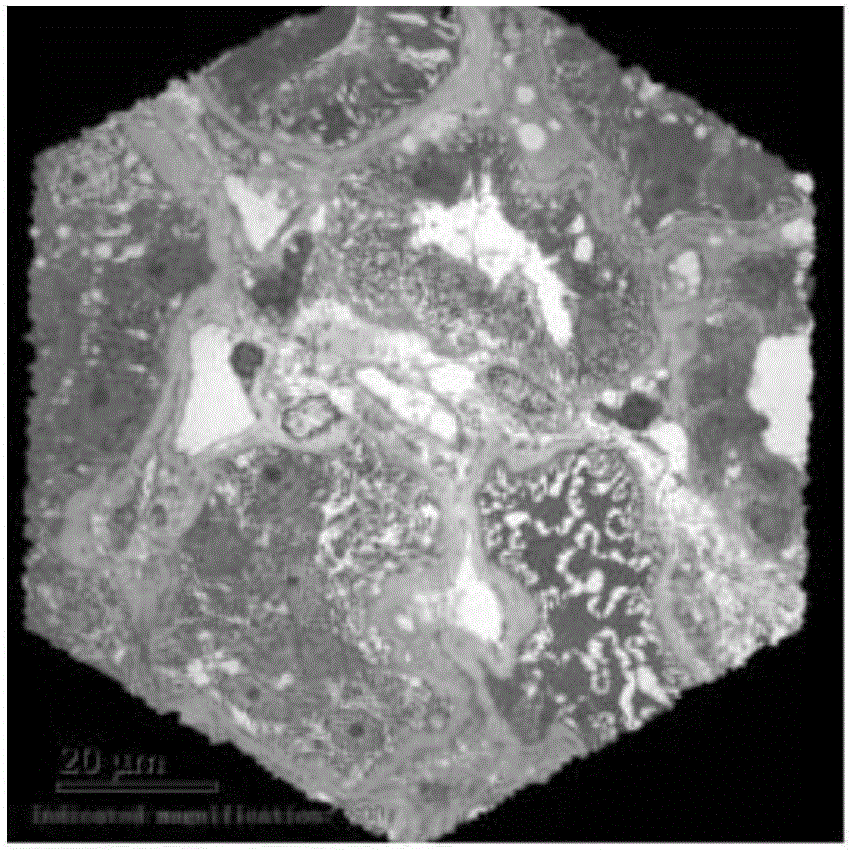

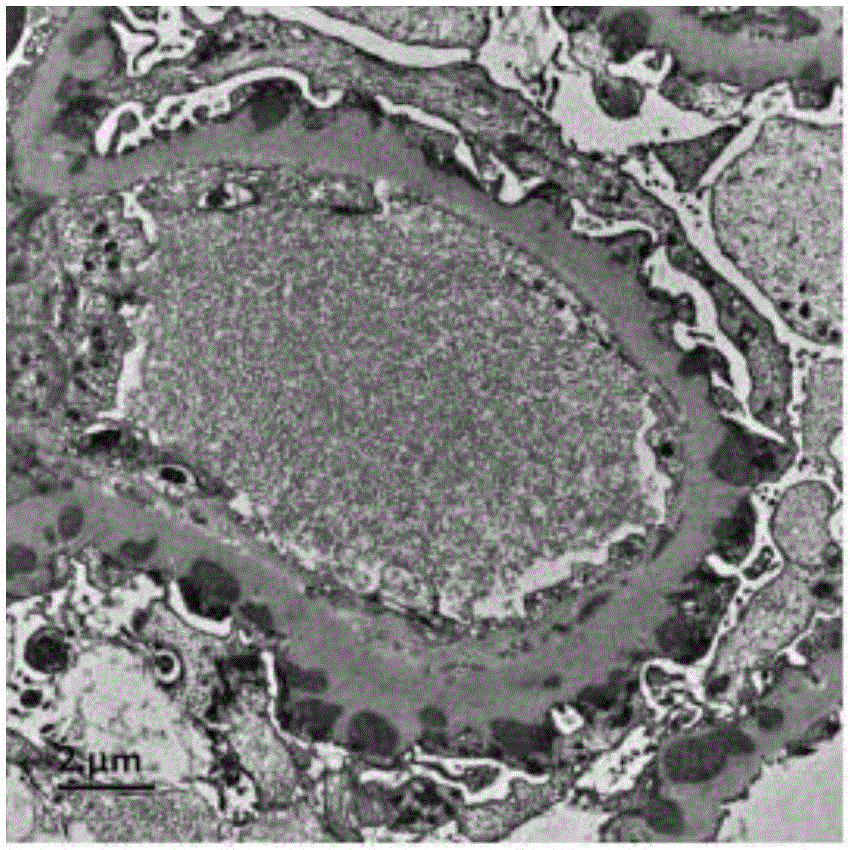

Image

Examples

Embodiment 1

[0032] Embodiment 1, a kind of vacuum staining method of electron microscope ultrathin section

[0033] S1 Load 80 pieces of the copper nets with slices on the dyed silica gel plate according to the serial number to get the stained plate;

[0034] S2 places the stained plate prepared in step S1 in a petri dish, and puts the petri dish in a vacuum preservation box, then absorbs the supernatant of the uranyl acetate solution, which is prepared by mixing 4 g of acetic acid The uranyl powder is dissolved in 100ml of methanol with a volume concentration of 68% and stirred and dissolved; centrifuged in a centrifuge at a speed of 6000r / min for 12min, and the supernatant is taken; the supernatant is added to the staining plate, covered and cultivated The lid of the dish is vacuumized, and the vacuum degree is 30.41kpa, and it is dyed for 30min under vacuum conditions;

[0035] S3 recover the uranyl acetate solution dyed in step S2, put the stained plate on the shelf, then rinse with ...

Embodiment 2

[0037] Embodiment 2, a kind of vacuum staining method of electron microscope ultrathin section

[0038] S1 Load 90 pieces of the copper nets with slices on the dyed silica gel plate according to the serial number to obtain the dyed plate;

[0039] S2 places the stained plate prepared in step S1 in a petri dish, and puts the petri dish in a vacuum preservation box, then absorbs the supernatant of the uranyl acetate solution, which is prepared by mixing 4 g of acetic acid The uranyl powder is dissolved in 100ml of methanol with a volume concentration of 68% and stirred and dissolved; centrifuged in a centrifuge with a speed of 6000r / min for 14min, and the supernatant is taken; the supernatant is added to the staining plate, covered and cultivated The lid of the dish is vacuumized, and the vacuum degree is 34.31kpa, and it is dyed for 30min under vacuum conditions;

[0040] S3 recover the uranyl acetate solution dyed in step S2, put the stained plate on the shelf, then rinse wit...

Embodiment 3

[0042] Embodiment 3, a kind of vacuum staining method of electron microscope ultrathin section

[0043] S1 Load 100 pieces of copper nets with slices on the dyed silica gel plate according to the serial number to get the dyed plate;

[0044] S2 places the stained plate prepared in step S1 in a petri dish, and puts the petri dish in a vacuum preservation box, then absorbs the supernatant of the uranyl acetate solution, which is prepared by mixing 4 g of acetic acid The uranyl powder is dissolved in 100ml of methanol with a volume concentration of 68% and stirred and dissolved; centrifuged in a centrifuge with a speed of 6000r / min for 16min, and the supernatant is taken; the supernatant is added to the staining plate, covered and cultivated Dish cover, carry out vacuum treatment, described vacuum degree is 39.21kpa, dyeing 30min under vacuum condition;

[0045] S3 recover the uranyl acetate solution dyed in step S2, put the dyed plate on the shelf, then rinse with double distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com