Vehicle ABS brake test bench capable of carrying out multiple tests

A technology of brake test and test bench, which is applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc. It can solve the problems of ABS performance testing, testing evaluation, and testing functions, etc., to achieve Simple operation, significant scientific research value, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

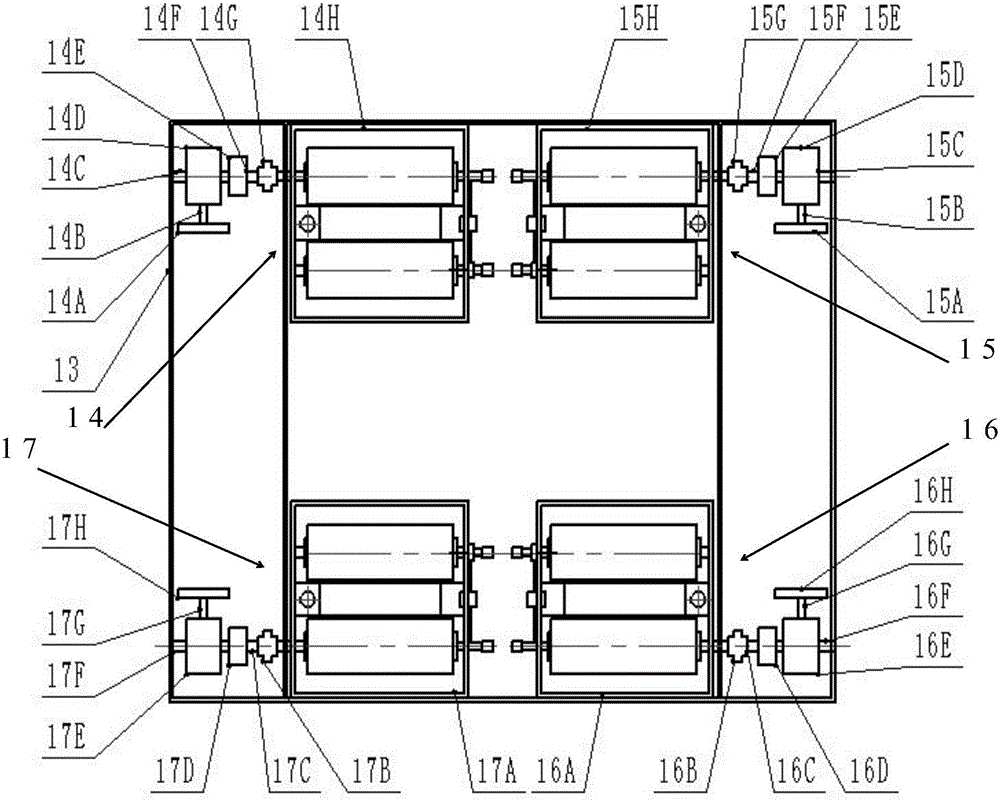

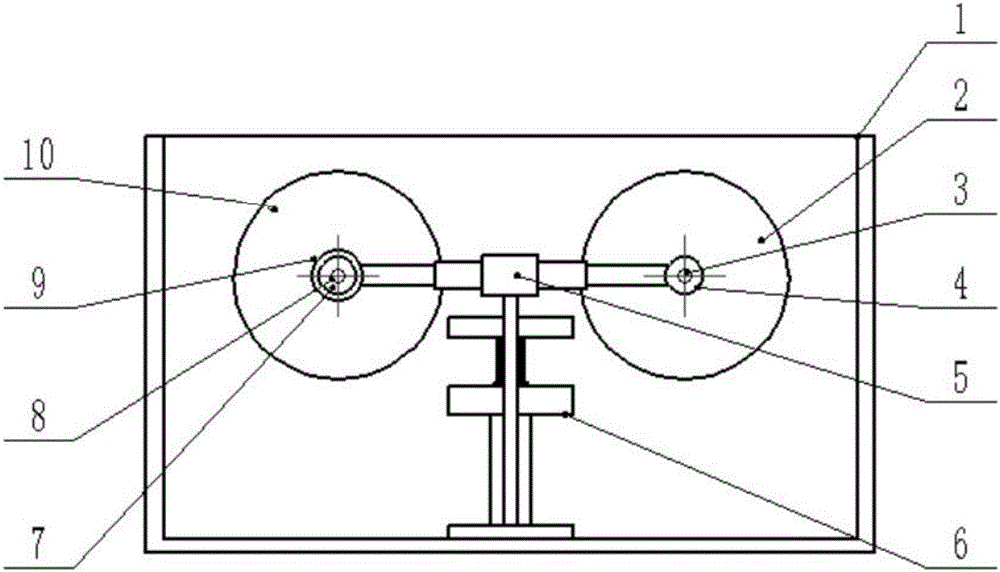

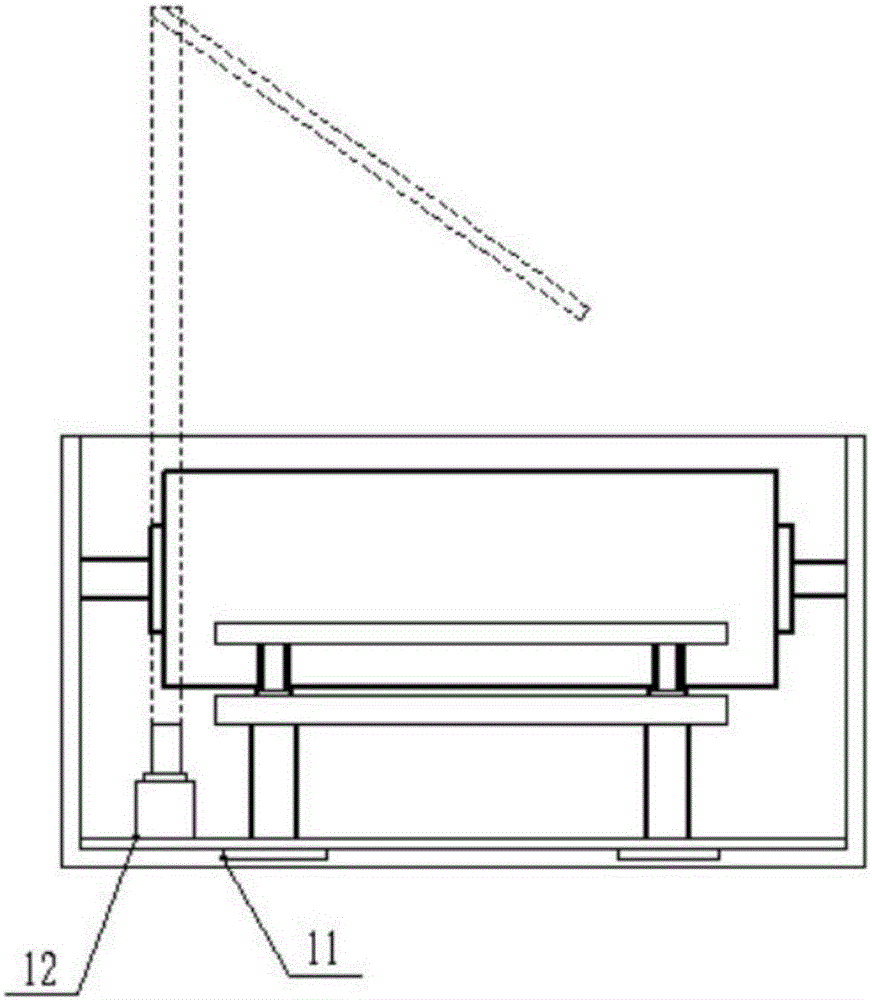

[0025] The invention provides a vehicle ABS test bench (abbreviated as test bench, see Figure 1-5 ). The test bench includes a frame platform 13, a front left wheel ABS brake test device assembly 14, a front right wheel ABS brake test device assembly 15, a rear right wheel ABS brake test device assembly 16, and a rear left wheel ABS brake test device assembly. Device assembly 17. The structure of the front left wheel ABS brake test device assembly 14, the front right wheel ABS brake test device assembly 15, the rear right wheel ABS brake test device assembly 16 and the rear left wheel ABS brake test device assembly 17 is exactly the same, The four are symmetrically installed on the four corners of the rack platform 13 with the central axis of the rack platform 13 as the center of symmetry.

[0026] The front left wheel ABS braking test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com