Off-line-type gas bag polishing tool finisher

An airbag polishing, off-line technology, used in manufacturing tools, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as troublesome operation and low efficiency of dressing devices, and achieve the effect of improving efficiency, enhancing rigidity and smooth swinging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

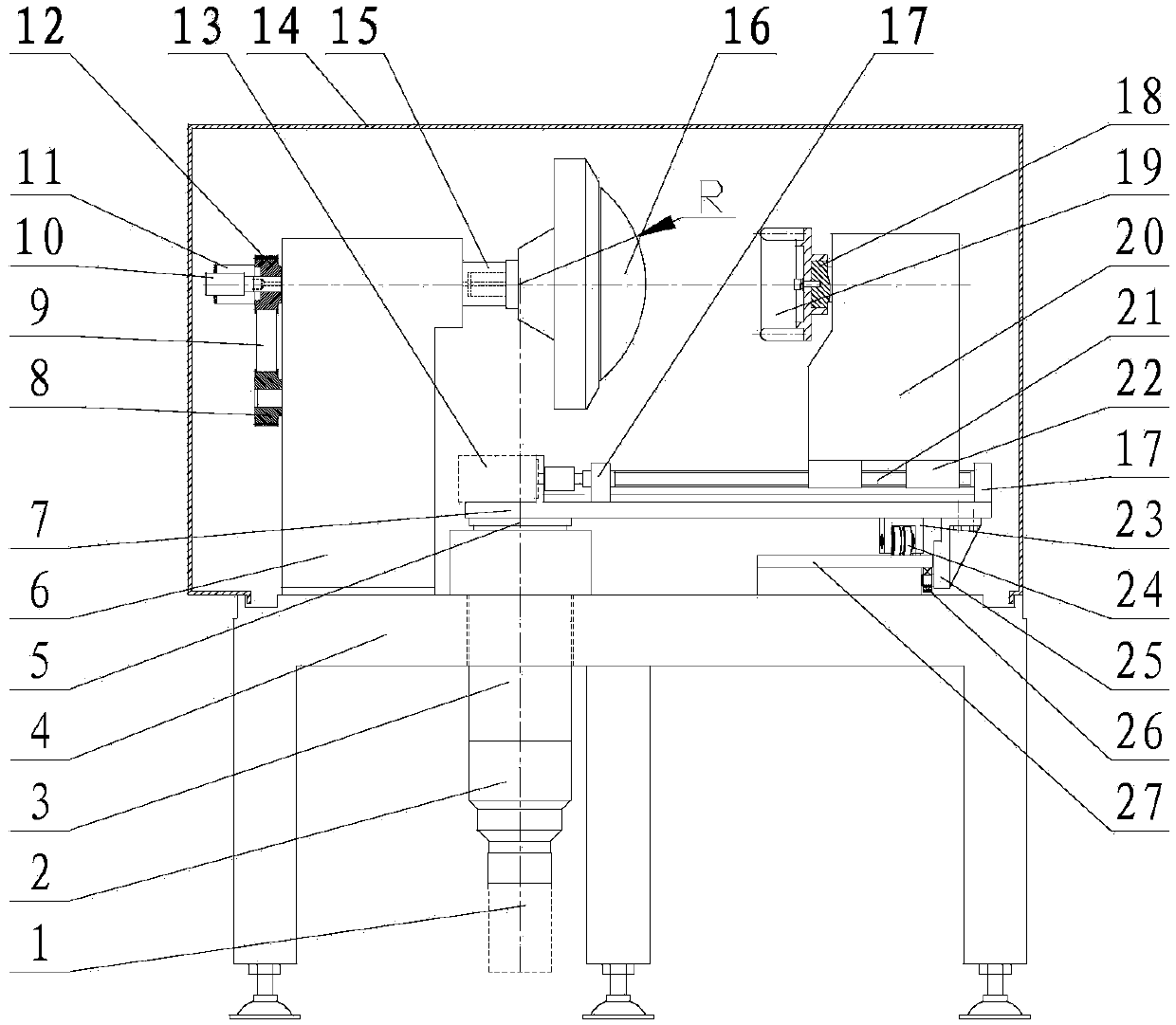

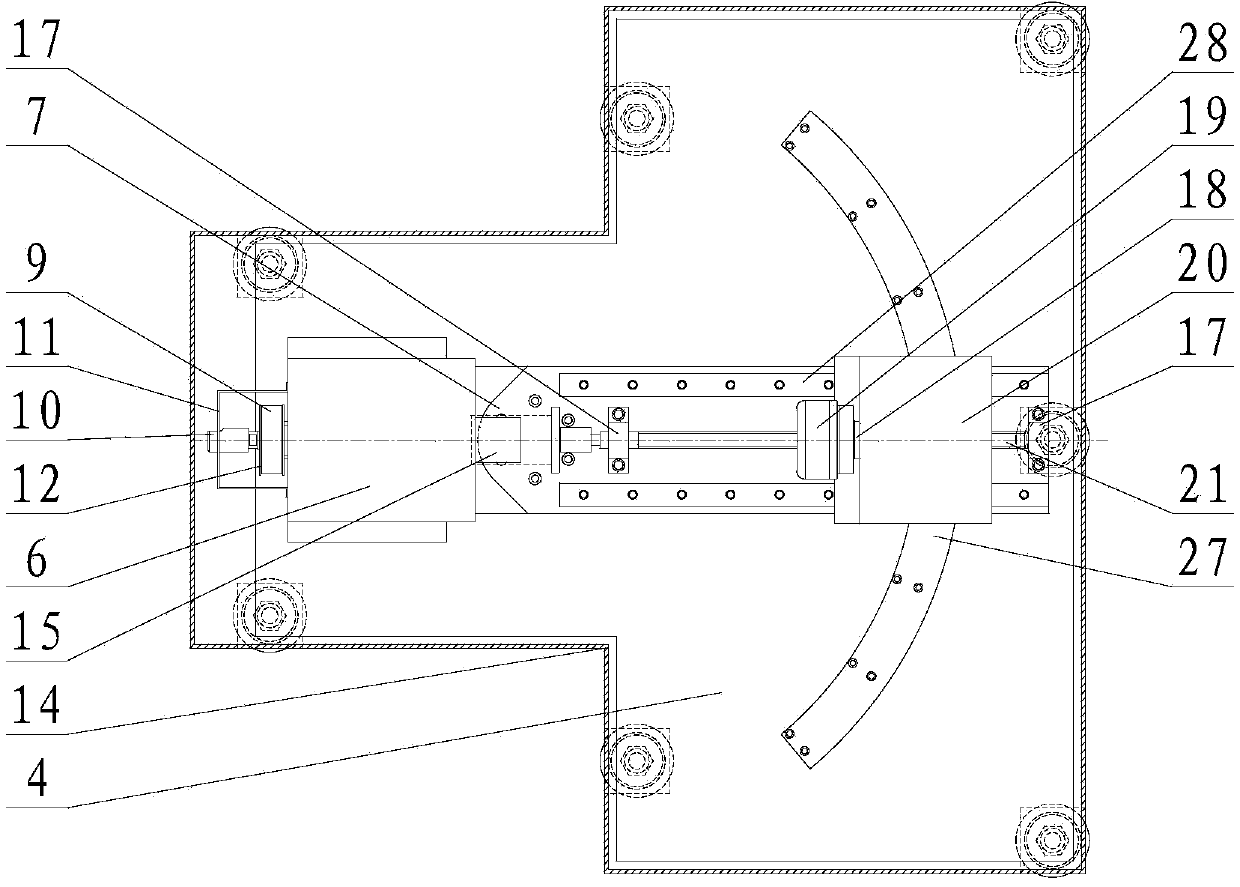

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

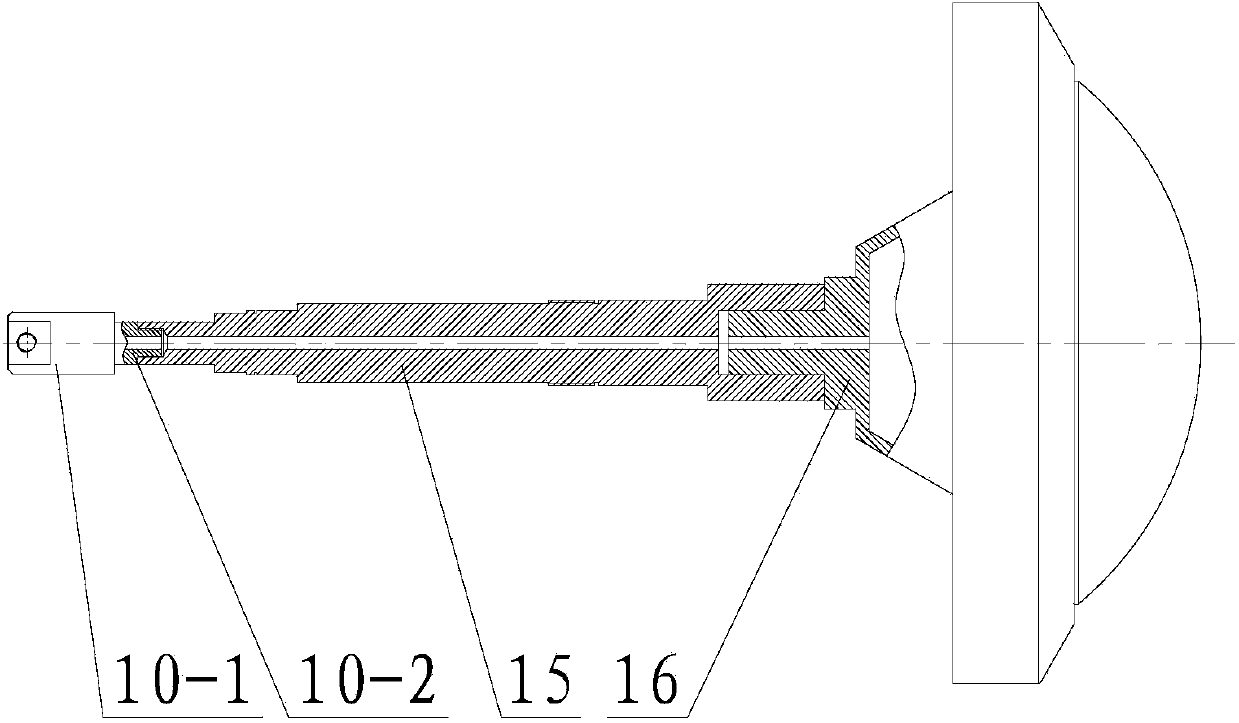

[0024] join figure 1 with 2 , the embodiment of the present invention is provided with swing motor 1, planetary reducer 2, swing spindle box 3, base 4, swing shaft 5, airbag spindle box 6, swing arm 7, driving wheel 8, belt 9, rotary joint 10, rotary joint Support 11, driven wheel 12, feed motor 13, protective cover 14, airbag main shaft 15, air bag tool 16, screw mandrel support 17, grinding wheel main shaft 18, dressing grinding wheel 19, grinding wheel main shaft box 20, screw mandrel 21, slide block 22, Swing arm support seat 23, support bearing 24, barb frame 25, barb bearing 26, circular arc guide rail 27, guide rail 28, air bag driving motor, grinding wheel driving motor.

[0025] Described dressing grinding wheel 19 is installed on the emery wheel main shaft 18, and emery wheel main shaft 18 is installed on the emery wheel headstock 20 and is driven to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com