Waste heat boiler system, rotary hearth furnace high temperature dusty flue gas treatment system and method

A flue gas treatment system and waste heat boiler technology, applied in the field of waste heat boiler systems, can solve the problems of complex flue gas composition, clogging of the flue gas treatment system, corrosion of equipment and flue alkali metals, etc., so as to improve the utilization rate of waste heat and the utilization of waste heat. effect, reduce the probability of clogging, improve the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

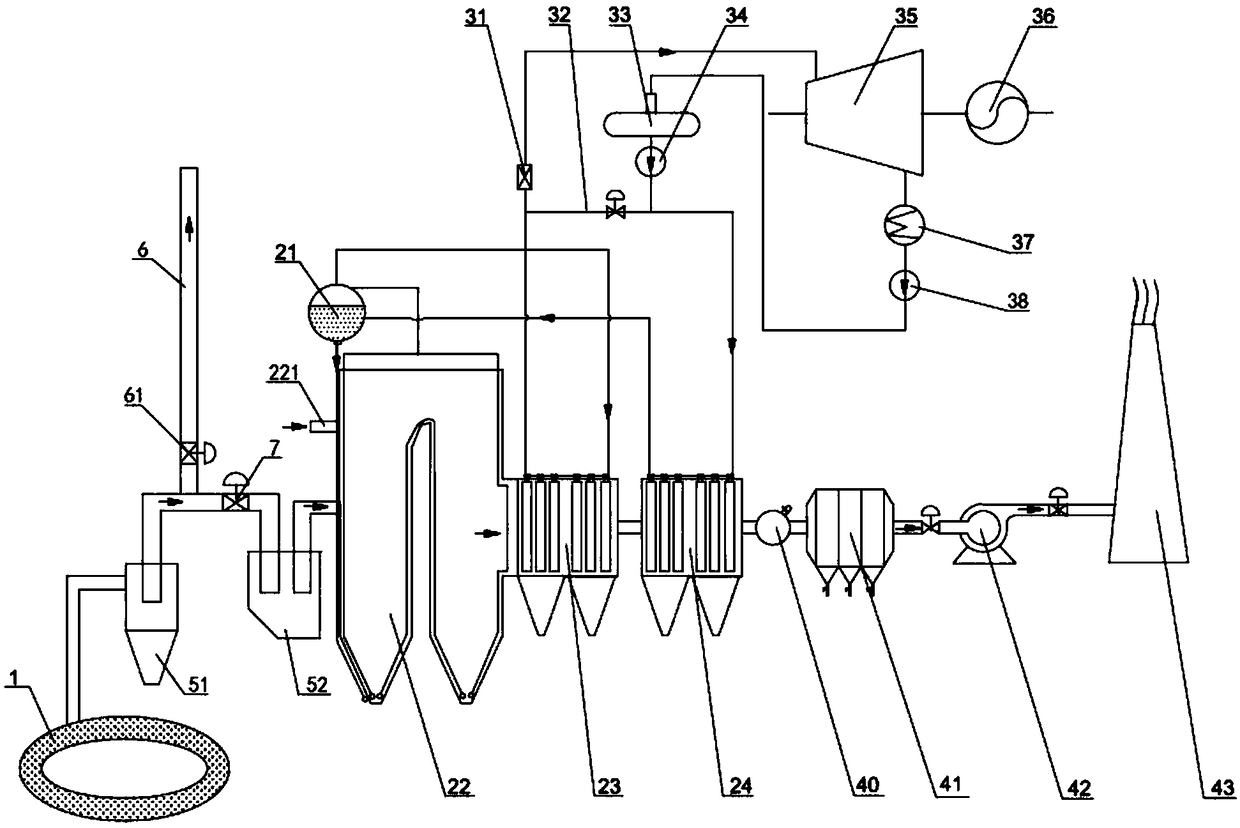

[0025] Such as figure 1 , the embodiment of the present invention provides a waste heat boiler system, including a settling furnace 22, a high-temperature heat exchange part 23, a low-temperature heat exchange part 24, and a steam drum 21. The heated wall of the settling furnace 22 is at least partially a water-cooled wall, and the The settling furnace 22 has an external flue gas inlet 221 for passing in external high-temperature flue gas to dilute the flue gas to be treated;

[0026] The steam drum 21 has a water inlet, a water outlet, an air inlet and an air outlet, the water outlet communicates with the heat exchange medium inlet of each of the water cooling walls, and the heat exchange between the air inlet and each of the water cooling walls The medium outlet is connected, the water inlet is connected with the heat exchange medium outlet of the low temperature heat exchange part 24 , and the air outlet is connected with the heat exchange medium inlet of the high temperatu...

Embodiment 2

[0038] Such as figure 1 , this embodiment relates to a rotary hearth furnace high-temperature dust-containing flue gas treatment system, which is equipped with a waste heat boiler system. The waste heat boiler system adopts the waste heat boiler system provided in the first embodiment above, and the specific structure will not be repeated here. The flue gas inlet of the settling furnace 22 communicates with the flue gas outlet of the rotary hearth furnace 1 through a high-temperature flue gas pipeline.

[0039] As one of the examples, such as figure 1 , the above-mentioned rotary hearth furnace high-temperature dust-laden flue gas treatment system also includes a pre-dust removal mechanism, and the rotary hearth furnace 1, the pre-dust removal mechanism and the settling furnace 22 are sequentially connected through a high-temperature flue gas pipeline. Wherein, the above-mentioned pre-dust removal mechanism preferably includes a water-cooled cyclone dust collector 51, and may...

Embodiment 3

[0054] The embodiment of the present invention relates to a method for treating flue gas from a rotary hearth furnace, which uses the high-temperature dust-laden flue gas treatment system of a rotary hearth furnace provided in the second embodiment above to treat the flue gas from a rotary hearth furnace. The specific structure of the system is as follows I won't repeat them here. The above method includes: when the flue gas from the rotary hearth furnace enters the downturn furnace 22 , the flue gas from the rotary hearth furnace is diluted by passing the external high temperature flue gas into the downturn furnace 22 . This method dilutes the flue gas of the rotary hearth furnace by introducing external high-temperature flue gas to reduce the dust concentration and the concentration of harmful components in the flue gas, which can prevent the sedimentation furnace 22, the high-temperature heat exchange part 23 and the low-temperature heat exchange part 24 from accumulating du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com