Novel firewood-coal-electricity integrated high-temperature equipment for ceramic firing

A high-temperature equipment, firewood and coal technology, applied in the direction of lighting and heating equipment, furnace type, charge control, etc., can solve the problems of increased yield, difficulty of firing, and reduction of personnel workload, so as to improve firing quality and temperature accuracy controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below in conjunction with specific embodiments.

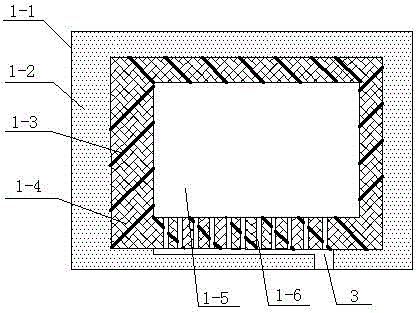

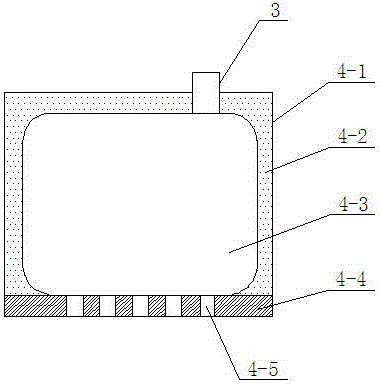

[0017] Such as Figure 1 to 4 As shown, a new type of diesel-coal-electric integrated high-temperature equipment for firing ceramics includes an electronically controlled high-temperature furnace 1, a diesel-coal combustion furnace 4, an ash pool 6 and a base 7. The surface of the electronically controlled high temperature furnace 1 is provided with an electric controller 2, and the lower bottom surface of the electronically controlled high temperature furnace 1 is provided with a number of legs 5 and fixed on the base 7 by the legs 5. The electronically controlled high temperature furnace 1 and the firewood coal combustion furnace 4 is connected through the flue gas channel 3, the electric-controlled high-temperature furnace 1 is located above the wood-coal combustion furnace 4, the electric-controlled high-temperature furnace 1 is used to provide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com