Method for automatically adjusting air door of ceramic kiln

A ceramic kiln and automatic adjustment technology, applied in the field of control, to achieve the effect of reducing labor intensity of workers, improving the quality of ceramic firing, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

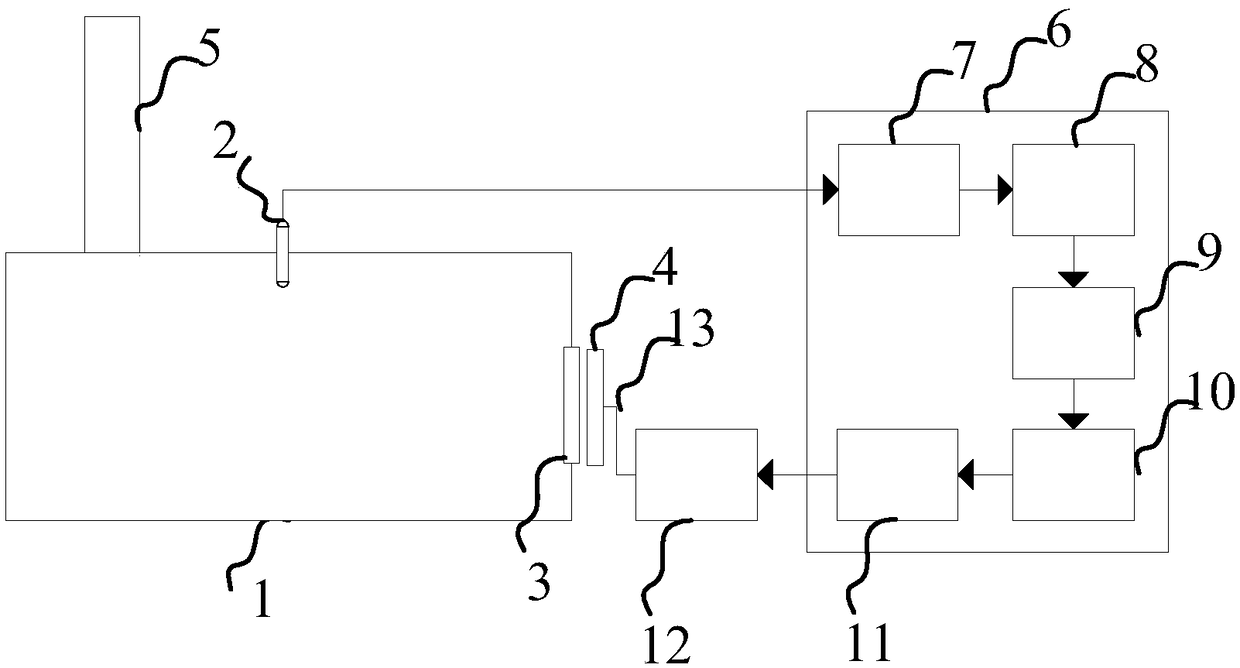

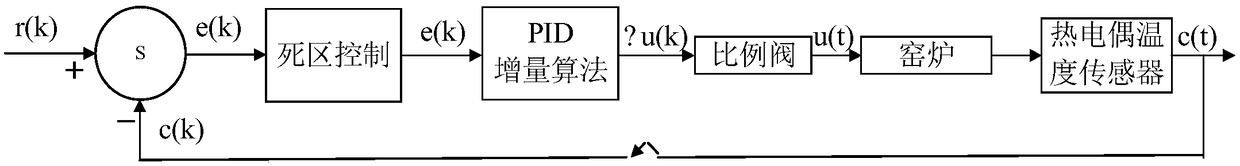

[0025] Such as figure 1 As shown, the porcelain kiln air door automatic adjustment system includes ceramic kiln 1, thermocouple temperature sensor 2, air door 3, air door baffle 4, flue 5, kiln controller 6, AD conversion module 7, temperature gauge 8, Control module 9 , switch value output module 10 , circuit drive module and relay 11 , electric push rod 12 and linkage device 13 .

[0026] Wherein, ceramic kiln 1 end is equipped with a damper 3, and damper 3 outlet is equipped with damper baffle 4, and damper baffle 4 can move up and down along guide rail, adjusts the opening degree of damper; Ceramic kiln 1 top is equipped with a flue, uses To remove the smoke in the furnace, adjust the oxidation atmosphere in the furnace together with the damper 3; a thermocouple temperature sensor 2 is also installed on the top of the ceramic kiln to obtain the real-time temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com