Bolt locking assembly

A bolt and anti-loosening technology, applied in the direction of bolts, threaded fasteners, screws, etc., can solve the problems of fatigue strength and durability of mechanical structures, failure of protective measures on the surface of bushings, and difficulty in lining and dismantling. The loose structure is simple and reliable, preventing scratches and meeting the requirements of anti-loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

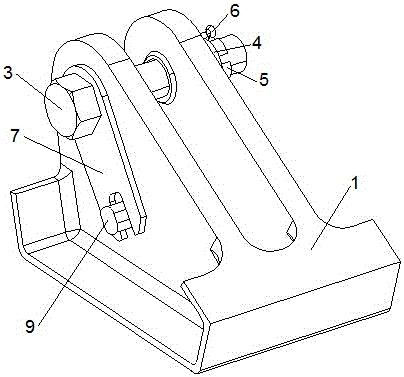

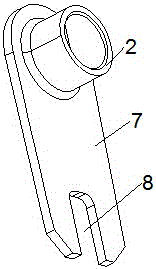

[0015] see Figure 1~Figure 2 A bolt anti-loosening assembly, including a joint 1, a bush 2, a bolt 3, a washer 4, a nut 5, a cotter pin 6, an ear piece 7, a notch 8 and a small boss 9; wherein, the bush 2 has ears There is a notch 8 on the lug 7 and the lug 7, and a small boss 9 is installed at the joint between the joint 1 and the notch 8 of the bushing 2. When installing, the notch 8 of the bushing 2 is stuck on both sides of the joint 1. At this time, the gap between the joint 1 and the bushing 2 can prevent the bushing 2 from rotating freely, the bolt 3 is inserted into the bushing 2 and passes through the joint 1, then the nut 5 is tightened, and the split pin 6 Insert the bolt 3, and take conventional anti-loosening measures, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com