Multilayer testing sampling valve

A technology of sampling valve and sampling cavity, which is applied in the direction of wellbore/well valve device, wellbore/well parts, earthwork drilling and mining, etc., can solve the problems that stratum sampling and multi-layer testing cannot be realized at the same time, and achieve convenient construction measures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

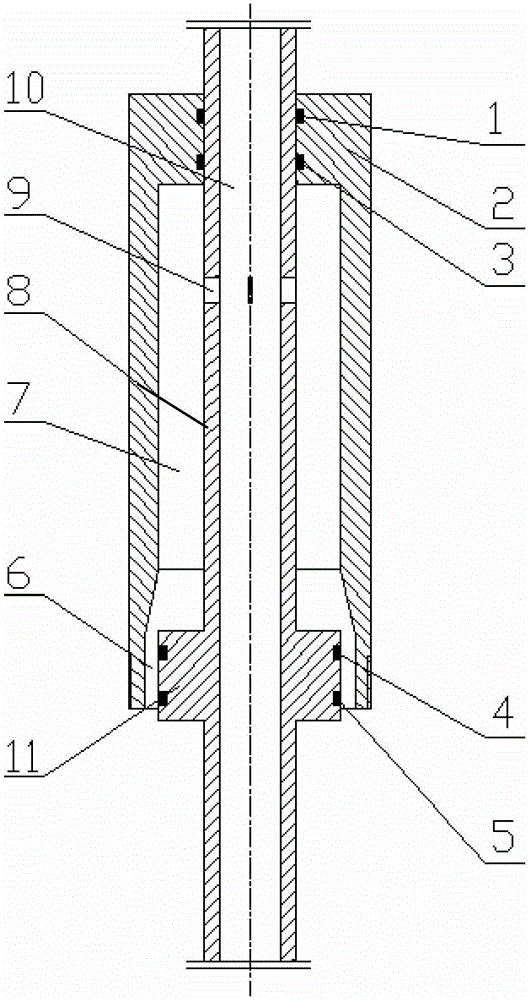

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

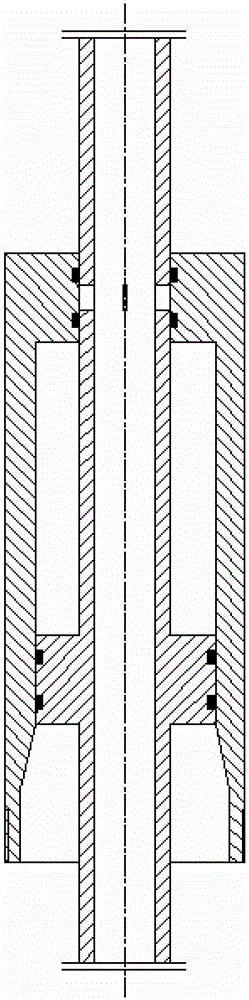

[0010] Such as figure 1 , 2 As shown, the multi-layer test sampling valve of the present invention includes a mandrel 8 and a housing 2, the housing 2 is cylindrical, and the passage of the bell mouth section 6 is formed in the lower section of the housing 2 inner cavity, and the housing 2 The top is provided with a through hole matching the outer diameter of the mandrel 8, the mandrel 8 with the main fluid channel 10 passes through the through hole, and two "o"-shaped sealing rings 1, 3 are embedded in the inner wall of the through hole, when the mandrel 8 plays a sealing role when moving up and down in the through hole, and forms a ring 11 on the outer wall of the lower half of the mandrel 8 that matches the inner cavity of the housing 2, and the outer peripheral surface of the convex ring 11 is embedded with two "o ” type sealing rings 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com