Waterproof construction method of roof of building

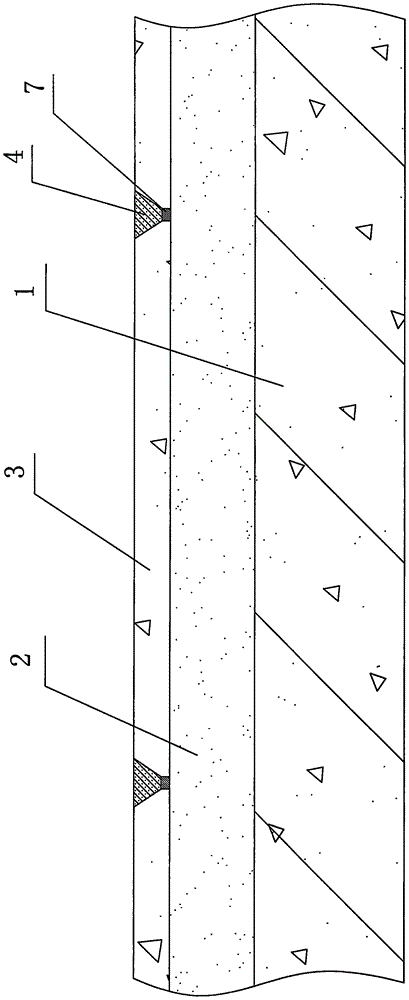

A construction method and building technology, which can be applied to building roofs, roof coverings, etc., can solve the problems of unstable concrete, failure of thermal insulation layer, easy access to coiled materials, etc., and achieve enhanced waterproof and leak-proof effect and anti-cracking performance. Good, avoid the effect of waterproof failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The specific production steps of silicone waterproofing agent are:

[0042] Step A, first add 850kg of cooling water at a temperature of 15 degrees Celsius to the reactor, and then quickly add CH to the reactor with a pump 3 SiCl 3 (ie: methyltrichlorosilane), CH 3 SiCl 3 React with water for 10 minutes, then stand for crystallization for 20 minutes, release the feed liquid, and filter to obtain the intermediate CH 3 Si(OH) 3 ;

[0043] Step B, weigh the intermediate CH produced in 150kg step A 3 Si(OH) 3 , Then add 800kg of water and 50kg of sodium hydroxide, heat for 10h, that is.

[0044] Reaction equation: CH 3 SiCl 3 +3H2O=CH 3 Si(OH) 3 +3HCl;

[0045] CH 3 Si(OH) 3 +3NaOH=CH 3 Si(ONa) 3 +3H 2 o

Embodiment 2

[0047] The preparation method of the silicone sand mixing solution is as follows: 1 kg of the silicone water repellent prepared in Example 1 is dissolved in 8 kg of water to prepare.

Embodiment 3

[0049] A kind of preparation method of cement mortar, its specific operation steps are:

[0050]Weigh 1kg of cement, 4kg of sand, and 0.5kg of organic silica sand mixing solution, mix and stir evenly to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com