Extrusion process

An extrusion method and extrusion hole technology, applied in the field of extrusion, can solve the problems of restricting the applicability of products, and achieve the effects of good ultraviolet radiation protection, accurate crosslinking degree and crosslinking density, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

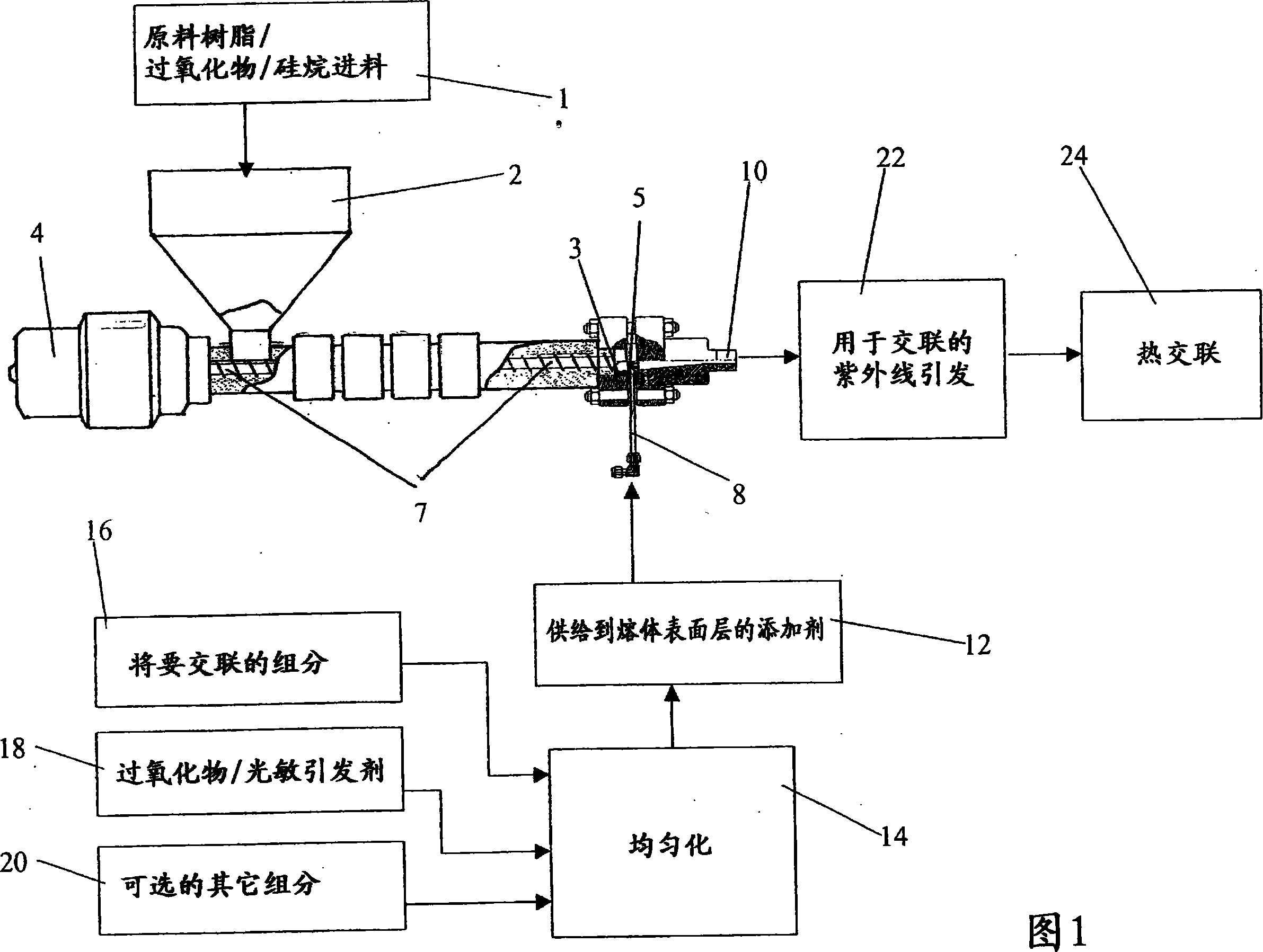

[0013] According to one embodiment of the present invention, a modified crosslinking additive or additives is applied to the surface of the thermoplasticized stream of extrudable resinous thermoplastic crosslinked material through an extrusion orifice prior to the actual extrusion step superior. In this case, the modified crosslinking additive is distributed over the resinous crosslinking material to form a surface layer with altered crosslinking properties relative to the rest of the resinous material to be extruded. Thus, the extruded article also includes a surface layer with altered crosslinking properties. This delivery of the modified cross-linking additive is accomplished using an introduction device. After the actual extrusion step, the cross-linking of the surface layer with altered cross-linking properties is initiated by means of an initiating device, and the cross-linking of the surface layer and the cross-linking of the rest of the extruded article continue using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com