A surface modification treatment method for an automobile inner cylinder

A surface modification and treatment method technology, applied in the field of quenching, can solve the problems of insufficient durable wear resistance, unfavorable machining, long treatment cycle, etc., and achieve the effect of reducing wave, reducing high temperature time, and short treatment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

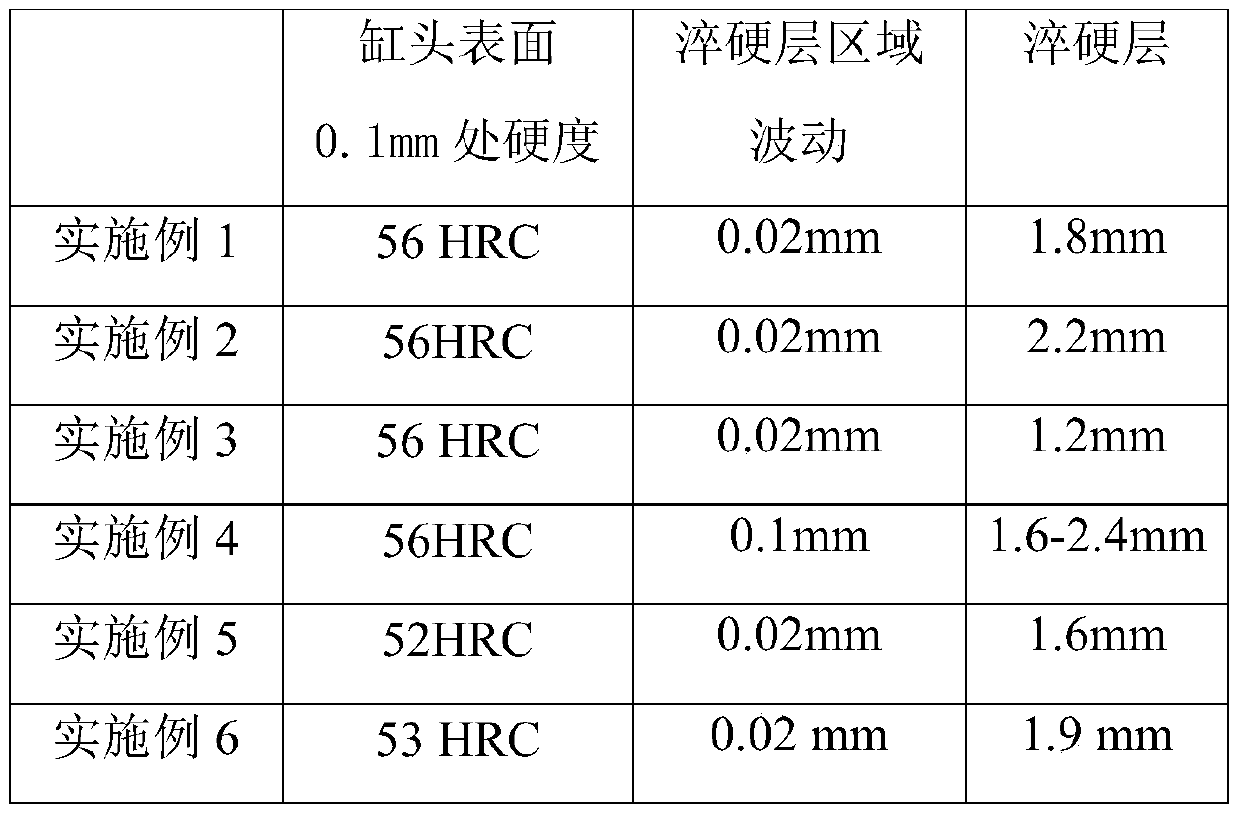

Examples

Embodiment 1

[0022] The frequency of the high-frequency quenching equipment of this embodiment is 250KHz, the anode voltage is 8.1KV±0.1, the anode current is 5.25A±0.25, the grid current is 0.725A±0.025, the downward moving speed is 300mm / min, and the workpiece rotation speed It is 444 revolutions / min.

[0023] The technological process of the surface modification treatment method of the automobile inner cylinder of the present invention includes: centering—opening cooling water—heating—water spray cooling, and the heating and water spray cooling are performed continuously.

[0024] Before quenching, place the workpiece on the upper and lower thimbles of the high-frequency quenching equipment; then select the induction coil that matches the workpiece, and then center a test rod with the same inner diameter as the induction coil so that the workpiece is positioned on the induction coil In the middle of the center, the defects of naked eye alignment can be reduced, and the workpiece can be ...

Embodiment 2

[0027] The frequency of the high-frequency quenching equipment of this embodiment is 250KHz, the anode voltage is 8.1KV±0.1, the anode current is 5.25A±0.25, the grid current is 0.725A±0.025, the downward moving speed is 280mm / min, and the workpiece rotation speed It is 440 rev / min.

[0028] The technological process of the surface modification treatment method of the automobile inner cylinder of the present invention includes: centering—opening cooling water—heating—water spray cooling, and the heating and water spray cooling are performed continuously.

[0029] Before quenching, place the workpiece on the upper and lower thimbles of the high-frequency quenching equipment; then select the induction coil that matches the workpiece, and then center a test rod with the same inner diameter as the induction coil so that the workpiece is positioned on the induction coil In the middle of the center, the defects of naked eye alignment can be reduced, and the workpiece can be prevente...

Embodiment 3

[0032] The frequency of the high-frequency quenching equipment of this embodiment is 250KHz, the anode voltage is 8.1KV±0.1, the anode current is 5.25A±0.25, the grid current is 0.725A±0.025, the downward moving speed is 320mm / min, and the workpiece rotation speed 450 rpm.

[0033] The technological process of the surface modification treatment method of the automobile inner cylinder of the present invention includes: centering—opening cooling water—heating—water spray cooling, and the heating and water spray cooling are performed continuously.

[0034] Before quenching, place the workpiece on the upper and lower thimbles of the high-frequency quenching equipment; then select the induction coil that matches the workpiece, and then center a test rod with the same inner diameter as the induction coil so that the workpiece is positioned on the induction coil In the middle of the center, the defects of naked eye alignment can be reduced, and the workpiece can be prevented from shi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com