Low-density ceramsite propping agent made from flint clay clinker and dolomite and preparation method of low-density ceramsite propping agent

A dolomite and low-density technology, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of large-scale and large-scale production of ceramsite proppants, unstable product performance, and mixing materials. Unevenness and other problems, to achieve the effect of reducing mining costs, reducing body density, and relieving operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

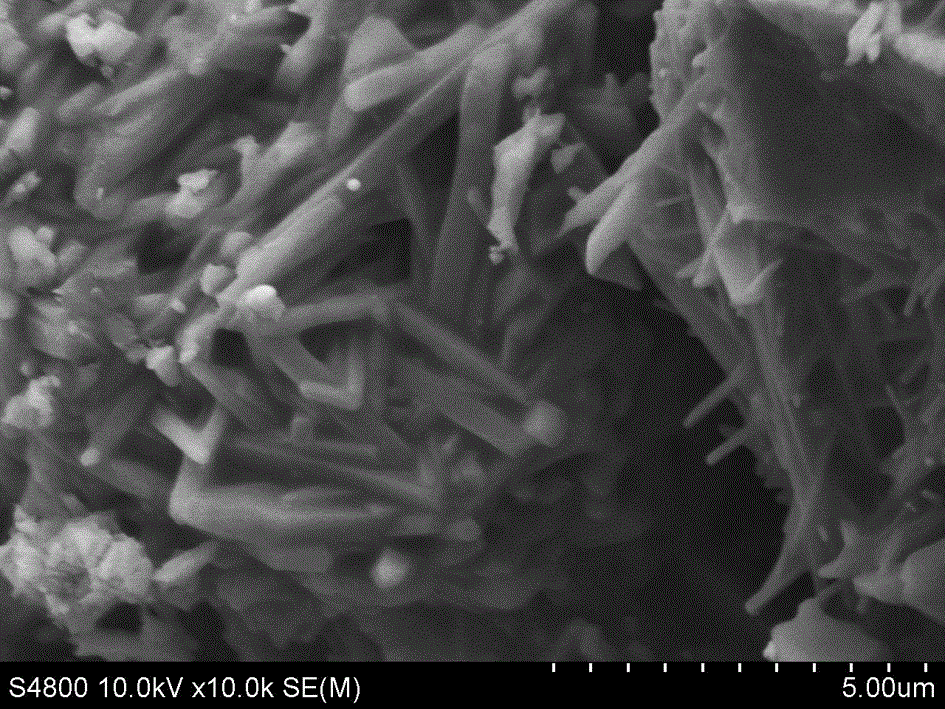

[0033] Such as figure 1 As shown, the low-density ceramsite proppant with burnt gem clinker and dolomite as raw materials, it includes burnt gem clinker and dolomite, the mass percentage of various raw materials is: burnt gem clinker 96%, dolomite 4% , the total amount of the burnt gem clinker and dolomite is 100%.

[0034] Further, the chemical composition of the burnt gem clinker is as follows by weight: Al 2 o 3 Content is 50%, SiO 2 The content is 32%, TiO 2 The content is 3%, Fe 2 o 3 The content is 1%, and the other content is 14%.

[0035] Further, the chemical composition of the dolomite is as follows by weight ratio: CaO content is 32%, MgO content is 22%, Fe 2 o 3 The content is 0.1%, SiO 2 The content is 1%, Al 2 o 3 The content is 0.05%, and the loss on ignition is 43.85%.

[0036] The method for preparing the above-mentioned low-density ceramsite proppant using burnt gem clinker and dolomite as raw materials is characterized in that it is carried out i...

Embodiment 2

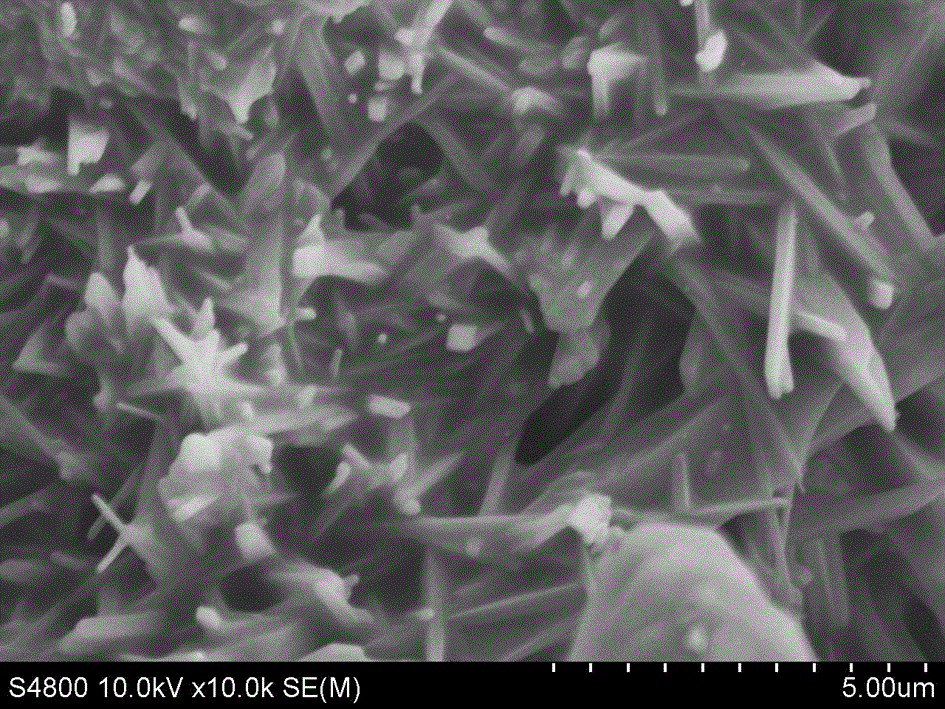

[0047] Such as figure 2 As shown, the low-density ceramsite proppant with burnt gem clinker and dolomite as raw materials, it includes burnt gem clinker and dolomite, the mass percentage of various raw materials is: burnt gem clinker 94%, dolomite 6% , the total amount of the burnt gem clinker and dolomite is 100%.

[0048] Further, the chemical composition of the burnt gem clinker is as follows by weight: Al 2 o 3 The content is 52%, SiO 2 The content is 31%, Fe 2 o 3 The content is 0.5%, TiO 2 The content is 3%, and the other content is 13.5%.

[0049] Further, the chemical composition of the dolomite is as follows by weight ratio: CaO content is 34%, MgO content is 23%, Fe 2 o 3 The content is 0.2%, SiO 2 The content is 0.8%, Al 2 o 3 The content is 0.08%, and the loss on ignition is 41.92%.

[0050] The method for preparing the above-mentioned low-density ceramsite proppant using burnt gem clinker and dolomite as raw materials is characterized in that it is ca...

Embodiment 3

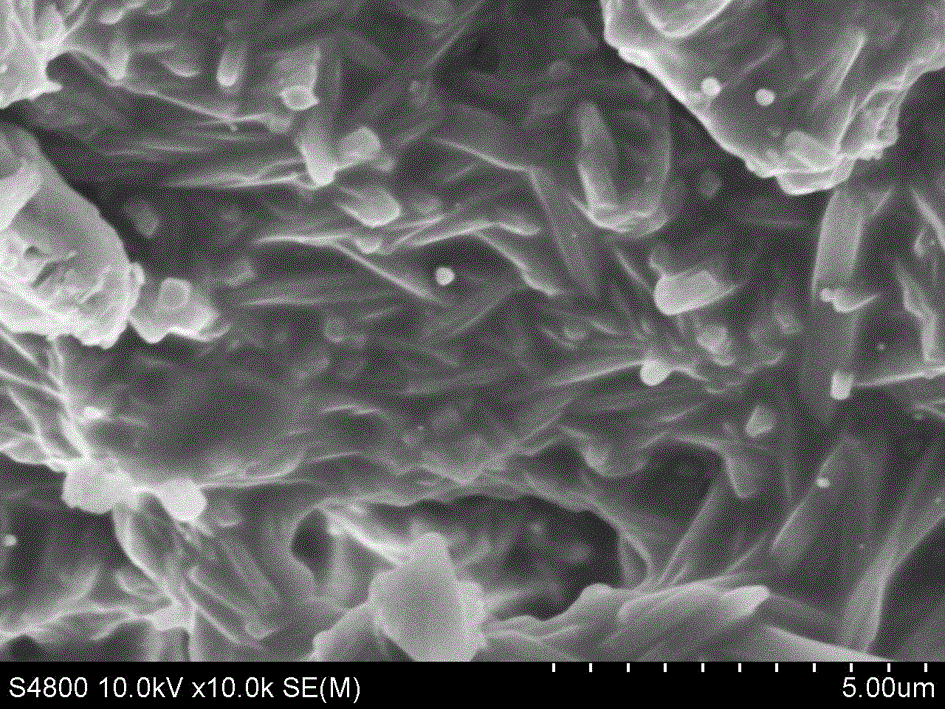

[0059] Such as image 3 As shown, the low-density ceramsite proppant with burnt gem clinker and dolomite as raw materials, it includes burnt gem clinker and dolomite, the mass percentage of various raw materials is: burnt gem clinker 90%, dolomite 10% , the total amount of the burnt gem clinker and dolomite is 100%.

[0060] Further, the chemical composition of the burnt gem clinker is as follows by weight: Al 2 o 3 The content is 54%, SiO 2 The content is 28%, Fe 2 o 3 Content is 1%, TiO 2 The content is 2.5%, and the other content is 14.5%.

[0061] Further, the chemical composition of the dolomite is as follows by weight ratio: CaO content is 35%, MgO content is 22%, Fe 2 o 3 The content is 0.2%, SiO 2 The content is 1.5%, Al 2 o 3 The content is 1%, and the loss on ignition is 41.3%.

[0062] The method for preparing the above-mentioned low-density ceramsite proppant using burnt gem clinker and dolomite as raw materials is characterized in that it is carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com