Refinement method for recovering butanol and octanol from butanol-octanol waste liquid through cracking reaction and hydrogenation reaction

A technology of hydrogenation reaction and refining method, applied in chemical instruments and methods, hydrogenation preparation, preparation of organic compounds, etc., can solve the problems of high energy consumption and low utilization rate of raw materials, so as to reduce separation cost, increase utilization value, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

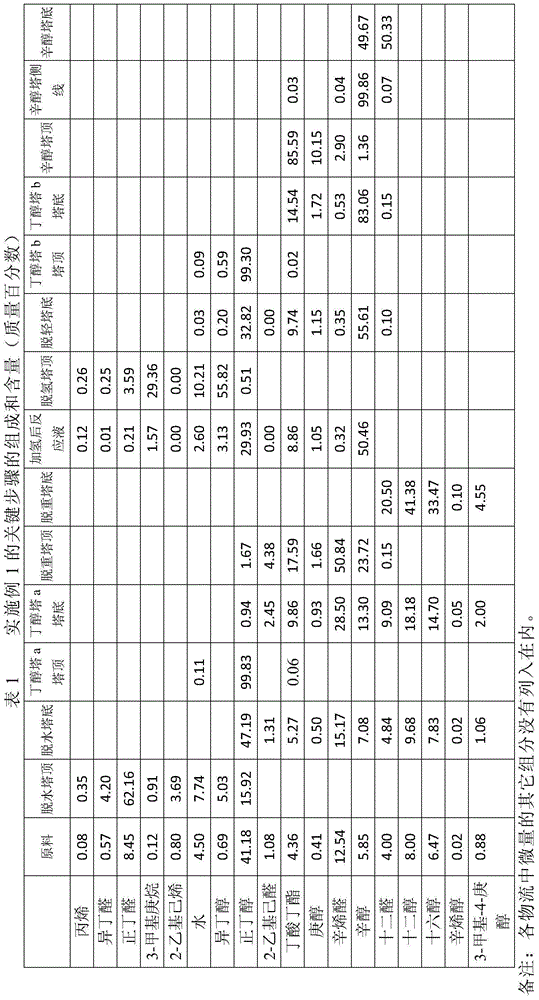

Embodiment 1

[0033] (1) Dehydration: The waste liquid of butanol and octanol enters the dehydration tower, and through the rectification process, water, hydrocarbons, isobutyraldehyde and n-butyraldehyde are distilled from the top of the dehydration tower, and the water phase is separated and discharged in the stratifier after being condensed, and the oil phase is discharged. Partial extraction, partial reflux, extracting the bottom stream from the bottom of the tower; the temperature at the top of the tower is 50°C, the pressure at the top of the tower is 0.12MPa, and the temperature of the bottom of the tower is 136°C;

[0034] (2) Separation of butanol a: the stream from the bottom of the dehydration tower enters the butanol tower a, and through the rectification process, the butanol product is extracted from the top of the butanol tower a, and the bottom stream is extracted from the bottom of the tower; the tower top temperature is 88°C, the pressure at the top of the tower is 0.03MPa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com