A method for eliminating molybdenum dioxide dripping material

A molybdenum dioxide and molybdenum trioxide technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, etc., can solve the problems of affecting the quality of molybdenum powder products, reducing the rate of first-class products, increasing water vapor, etc., and achieving the elimination of molybdenum dioxide. The effect of dripping water, improving the first-grade product rate and reducing the oversize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

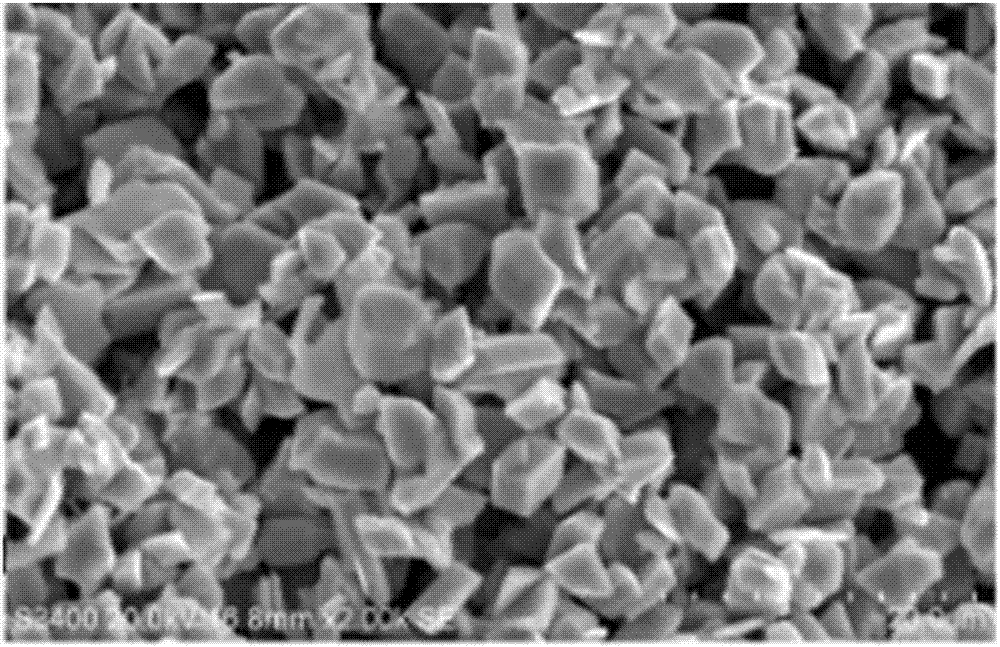

[0044] Select molybdenum trioxide (MoO 3 ) as the preparation raw material; the selected molybdenum trioxide (MoO 3 ) color is off-white, and the control index is: Fisher particle size is 9.2μm, bulk density is 1.52g / cm 3 , K content is 96ppm, other chemical components are uniform and qualified, and the morphology is relatively regular and non-agglomerated;

[0045] Choose molybdenum trioxide (MoO 3 ), first wrap the standpipe part of the hydrogen return pipeline with thermal insulation material, and the thickness of the thermal insulation material is 5cm; then fix it with a stainless steel screen, and fasten the edge of the screen with fine iron wire to facilitate the fixation; finally Then wrap a thin aluminum-plastic plate on the outside of the screen, and fix the interface of the aluminum-plastic plate with rivets; among them, the thermal insulation material is a high-aluminum ceramic fiber blanket produced by Shandong Luyang Co., Ltd., model LYGX-422; the stainless stee...

Embodiment 2

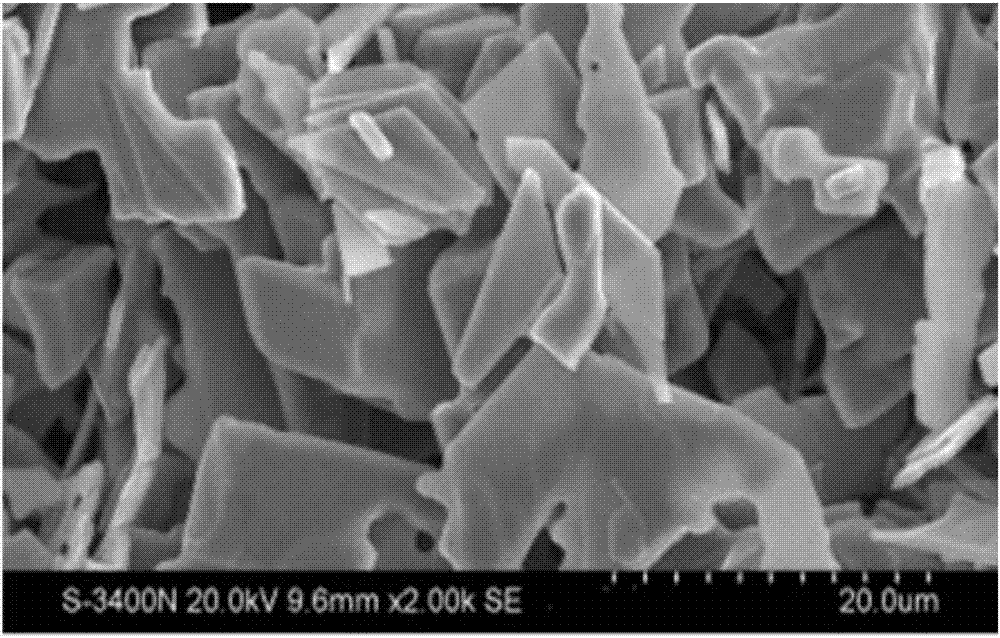

[0050] Select molybdenum trioxide (MoO 3 ) as the preparation raw material; the selected molybdenum trioxide (MoO 3 ) color is off-white, the control index is: Fibonacci particle size is 6μm, bulk density is 1.4g / cm 3 , K content is 92ppm, other chemical components are uniform and qualified, and the morphology is relatively regular and non-agglomerated;

[0051] Choose molybdenum trioxide (MoO 3 ), first use insulation material to wrap the standpipe of the hydrogen return pipeline, and the thickness of the insulation material is 4cm; then fix it with a stainless steel screen, and the edge of the screen should be fastened with fine iron wires to facilitate the fixation; finally; Then wrap a thin aluminum-plastic plate on the outside of the screen, and fix the interface of the aluminum-plastic plate with rivets; among them, the thermal insulation material is a high-aluminum ceramic fiber blanket produced by Shandong Luyang Co., Ltd., model LYGX-422; the stainless steel screen ...

Embodiment 3

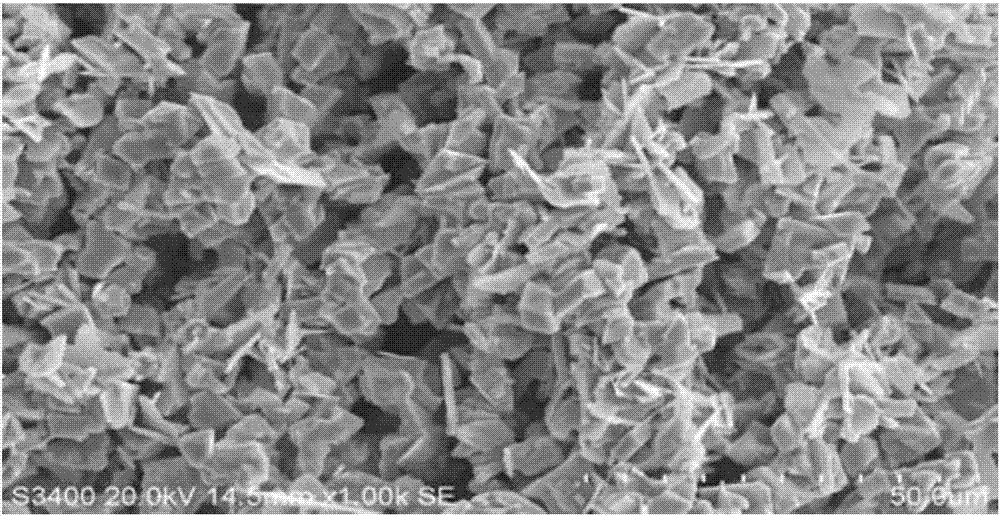

[0056] Select molybdenum trioxide (MoO 3 ) as the preparation raw material; the selected molybdenum trioxide (MoO 3 ) color is off-white, and the control index is: Fisher particle size is 15μm, bulk density is 1.6g / cm 3 , K content is 130ppm, other chemical components are uniform and qualified, and the morphology is relatively regular and non-agglomerated;

[0057] Choose molybdenum trioxide (MoO 3 ), first wrap the standpipe of the hydrogen return pipeline with thermal insulation material, and the thickness of the thermal insulation material is 6cm; then fix it with a stainless steel screen, and the edge of the screen should be fastened with fine iron wire, so as to be fixed firmly; finally Then wrap a thin aluminum-plastic plate on the outside of the screen, and fix the interface of the aluminum-plastic plate with rivets; among them, the thermal insulation material is a high-aluminum ceramic fiber blanket produced by Shandong Luyang Co., Ltd., model LYGX-422; the stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com