Pneumatic tire repairing device

A tire repair and pneumatic technology, applied in the direction of tires, other household appliances, household appliances, etc., can solve the problems of increased movement paths, wasted time in assembly, and the speed of tire repair fluid cannot be accelerated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

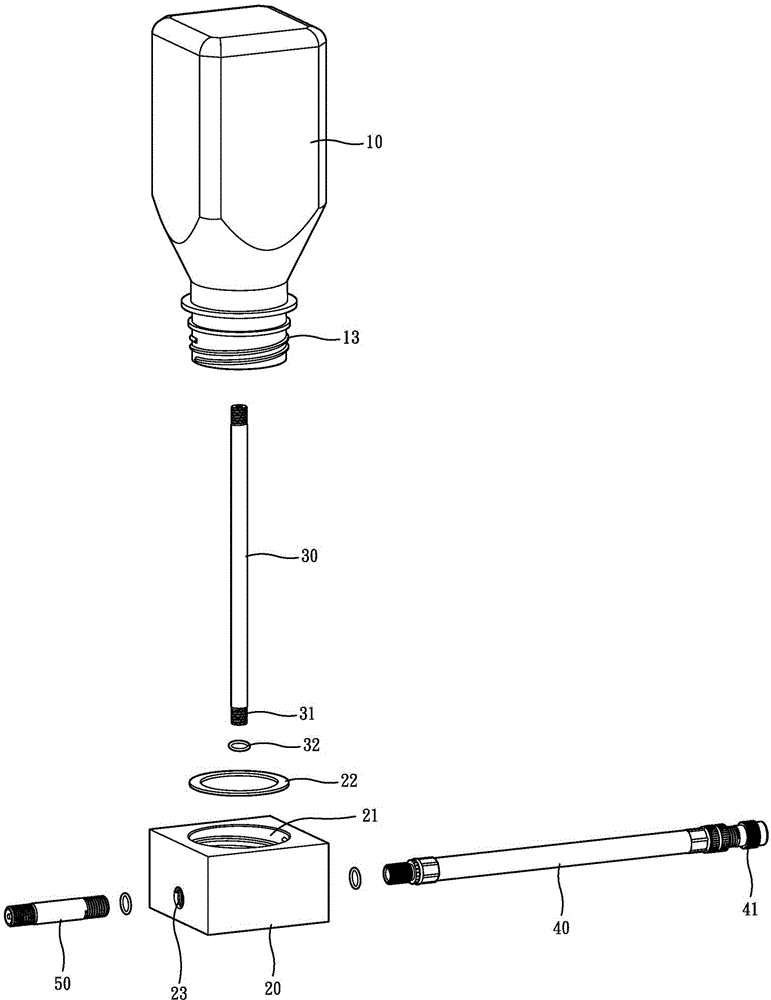

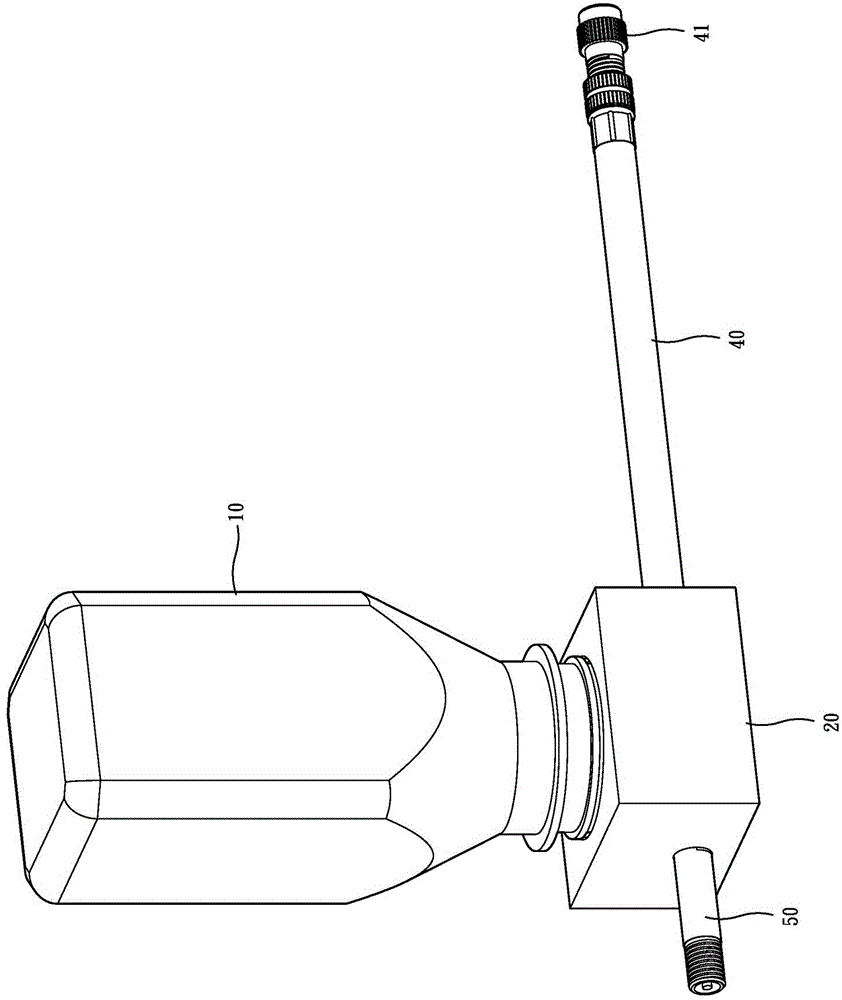

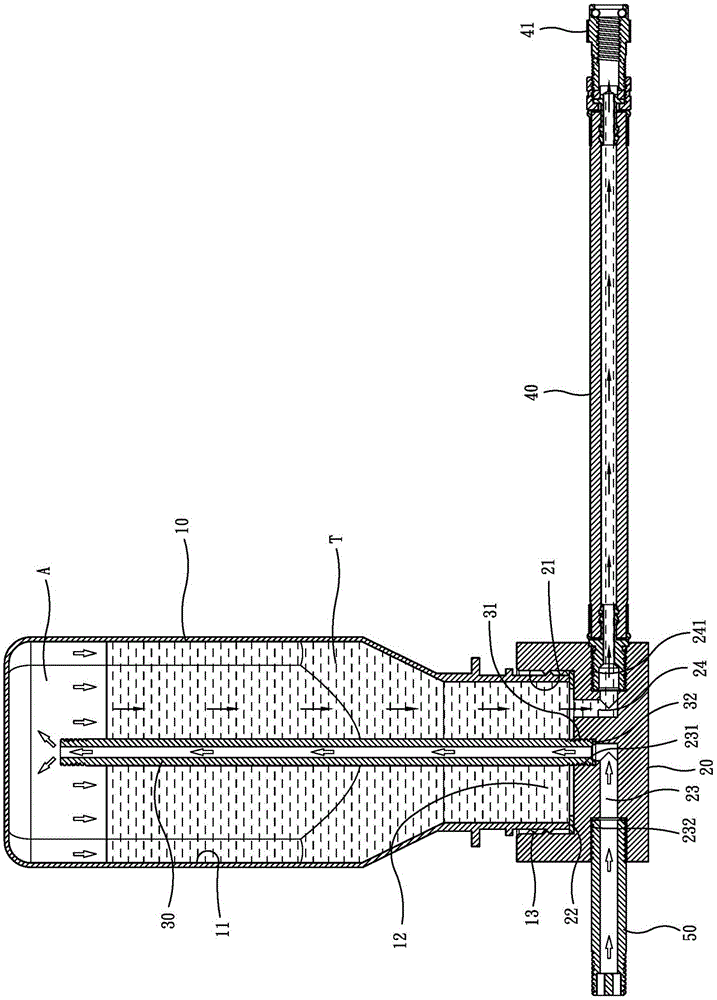

[0045] Please see Figure 1 to Figure 4 , the present invention includes a bottle body 10, a valve cover 20, an air guide tube 30, a throat pipe 40 and a pipe joint 50; wherein:

[0046] The bottle body 10 has a chamber 11 inside, and its bottom end has a bottle mouth 12 that communicates with the inside and outside of the chamber 11, and an external thread 13 is provided on the outer periphery of the bottle mouth 12;

[0047] The valve cover 20 has an internal screw hole 21 that can be assembled with the external thread 13, so that the valve cover 20 can be a detachable closed bottle mouth 12. In order to maintain the sealing effect, its bottle mouth 12 and the internal screw hole 21 are in contact A first seal ring 22 is installed at the connected part; the valve cover 20 is also provided with an air inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com