A rough and fine composite CNC machining center machine tool

A technology of machining centers and machine tools, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing equipment investment, low speed, time-consuming, etc., and achieve the effect of great practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

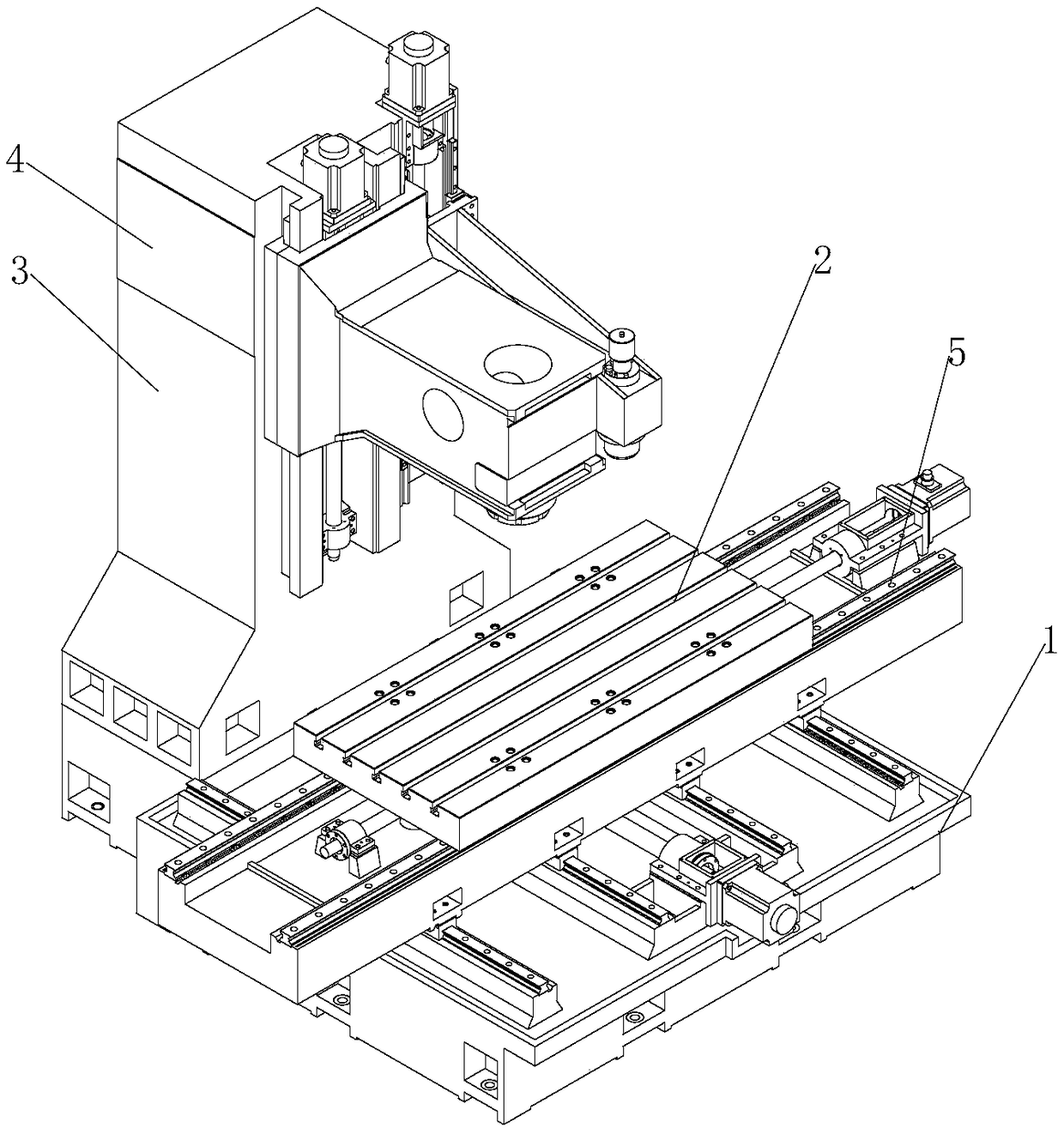

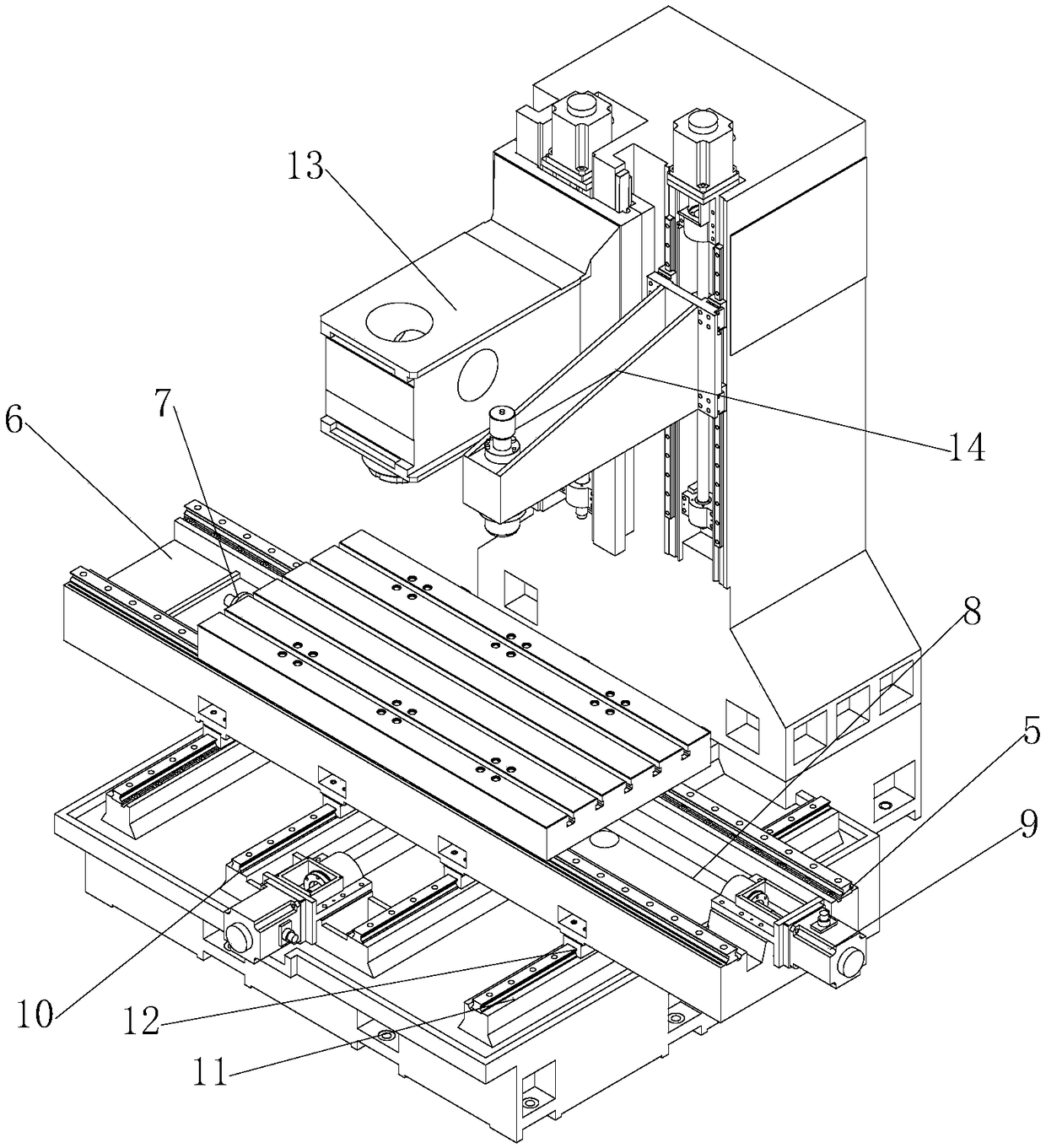

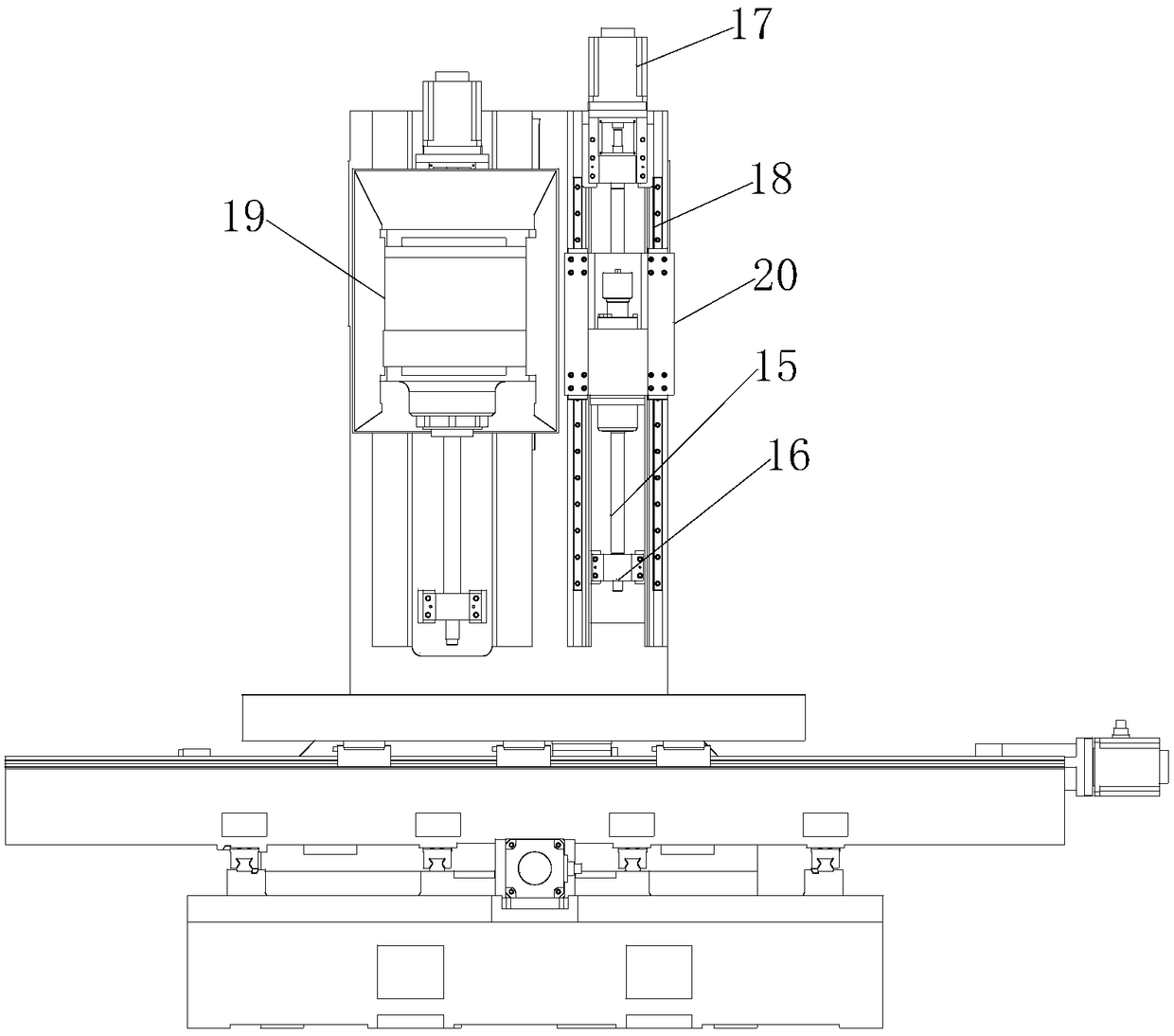

[0020] As shown in the accompanying drawings, a rough-fine composite CNC machining center machine tool includes a base 1, a mobile device installed on the base 1, a workbench 2 movably installed on the mobile device, a column 3 installed on the back of the base 1, and a The thick and thin double-head composite structure on the column 3, the power device and the automatic tool changer 4 installed on the column 3, in order to improve the stability of the device, increase the length and width of the bottom surface of the base 1, and increase the length of the bottom surface of the column 3 with width.

[0021] The mobile device includes a horizontally installed linear track 5 and a vertically installed linear track 5. The linear track 5 includes a sadd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com