Special machine tool for deburring three-way valve and four-way valve

A special machine tool and four-way valve technology, applied in the field of machine tools, can solve the problems of increased procedures, working hours, low efficiency, poor consistency, etc., and achieve the effects of reducing operation time, fast operation, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

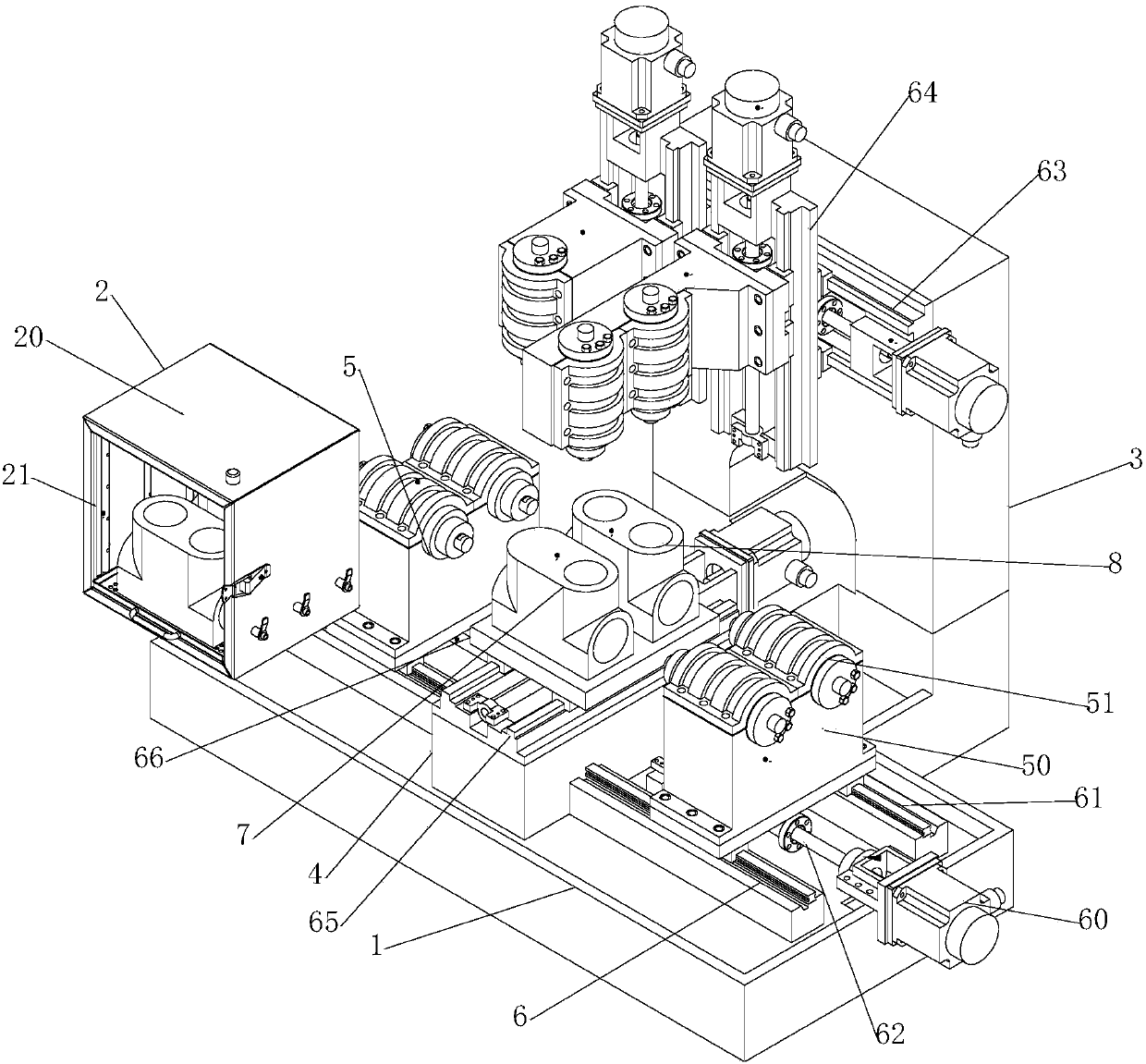

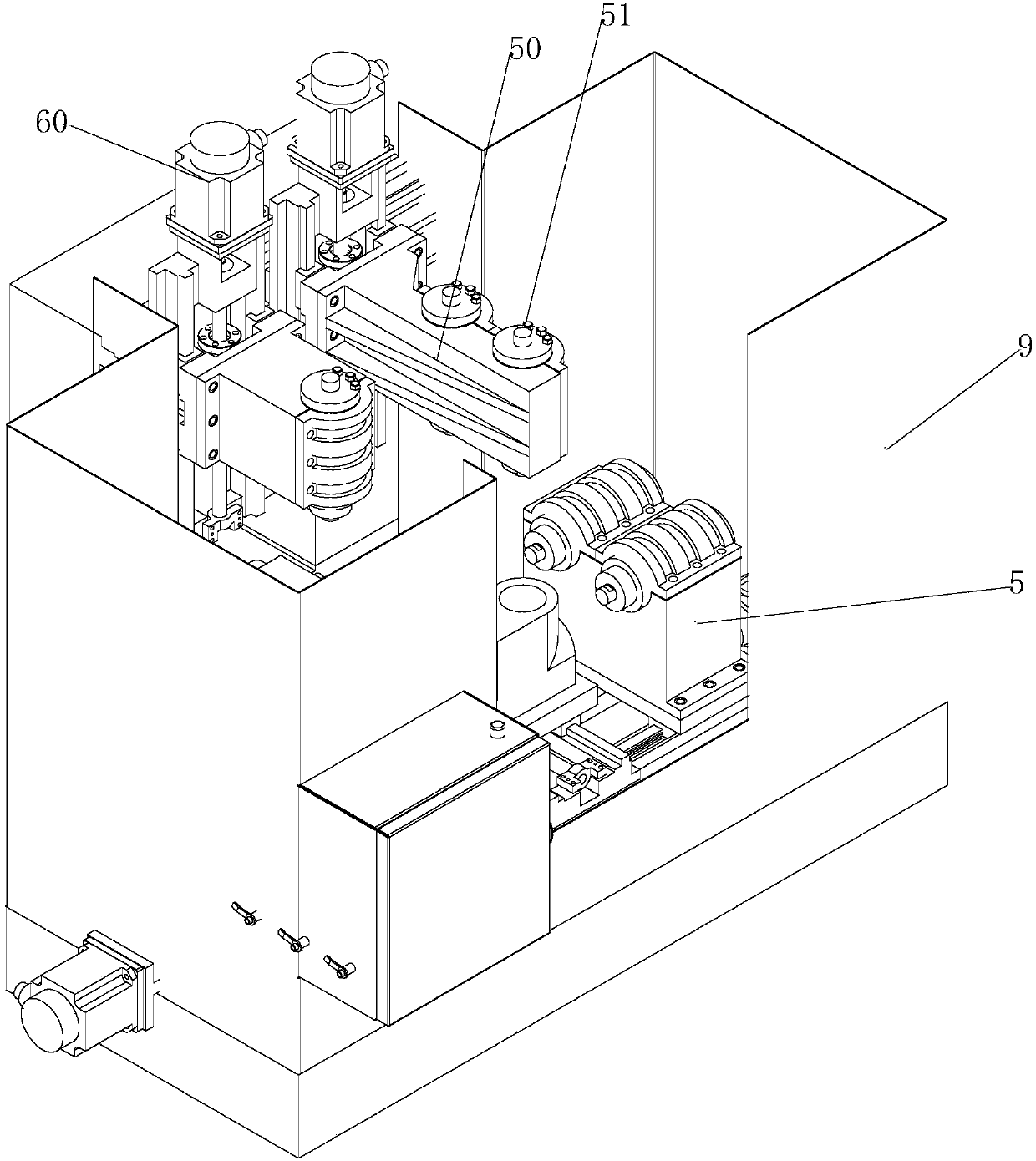

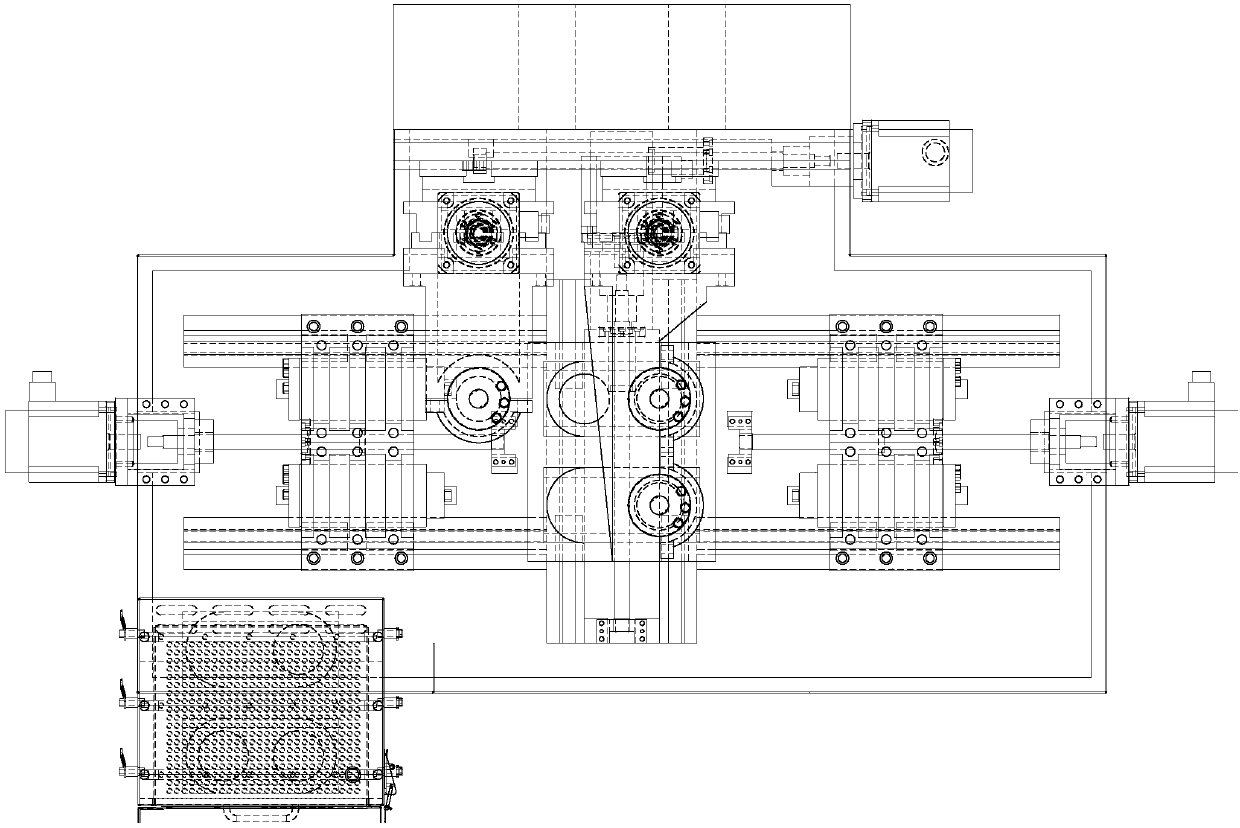

[0020] Please refer to the accompanying drawings, a special machine tool for deburring three-way valves and four-way valves, including a base 1, a flushing tank 2, a column 3, a processing table 4, a spindle box 5 and a ball screw horizontally arranged on the ground The track 6, the ball screw track 6 includes a motor 60, a linear track 61, and a screw 62. The screw 62 is connected to the motor 60 in transmission, parallel to the linear track 61 and rotatably installed between the linear tracks 61, and the column 3 is fixed on the base On one side, an X-direction ball screw track 63 is arranged laterally on the side of the column 3 close to the base, and two parallel Y-direction ball screw tracks 64 are slidably installed perpendicular to the X-direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com