Automatic nut and gasket screwing device

A technology for screwing nuts and bolt washers, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor quality consistency and low efficiency, and achieve the effect of good quality consistency and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

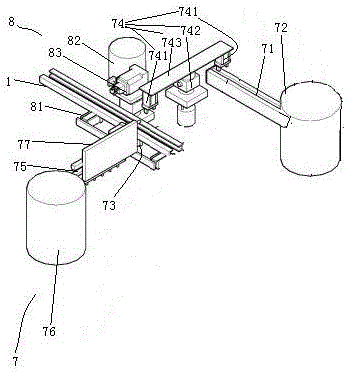

[0024] Embodiment one, see figure 1 , a device for automatically screwing nuts and washers, including a workpiece moving guide groove 1, a chassis 2, a bolt sleeve washer mechanism 7 and a nut assembly mechanism 8. The workpiece moving guide groove 1 is a linear structure. The workpiece moving guide groove 1 is inclined to be set with the mode that the right end is high and the left end is low. The underframe 2 is located below the workpiece moving guide groove 1 and is connected with the underframe 2 . Wear bolt sleeve washer mechanism 7 and nut assembly mechanism 8 and six are distributed successively from right to left.

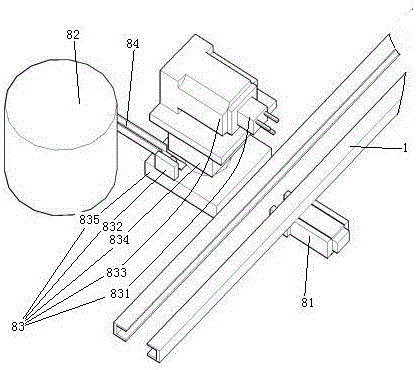

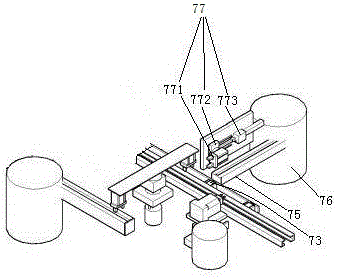

[0025] The bolt sleeve washer mechanism 7 includes a washer vibrating plate 72 provided with a washer queuing discharge trough 71, a bolt washer assembly position workpiece fixing mechanism 73, a washer transfer mechanism 74 one by one, a bolt vibrating plate 76 and a bolt queuing discharge chute 75 are provided with Bolt transfer mechanism 77 one by on...

Embodiment 2

[0036] Embodiment two, the difference with embodiment one is:

[0037] see Figure 4 , Underframe 2 is provided with vibration isolation seat 9. The vibration isolation seat 9 includes a vertical damping oil cylinder 91 and a shock absorbing spring 92 sleeved on the damping oil cylinder. The damping oil cylinder 91 includes a damping oil cylinder body 911 . The damping oil cylinder body 911 is connected with the bottom frame 2 together. A first piston 912 is disposed inside the damping oil cylinder body 911 . The first piston 912 is connected to the supporting seat 93 through the piston rod 913 . One end of the damping spring 92 is affixed together with the piston rod 913, and the other end is affixed together with the cylinder body 911 of the damping oil cylinder.

[0038] see Figure 5 , The second piston 914 and the separation plate 94 are also provided in the damping cylinder body 911 . The separating plate 94 and the damping oil cylinder body 911 are affixed togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com