High-precision bar rolling mill

A high-precision, rolling mill technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems that cannot meet the product specification requirements, and achieve the effect of compact structure, easy disassembly and assembly, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

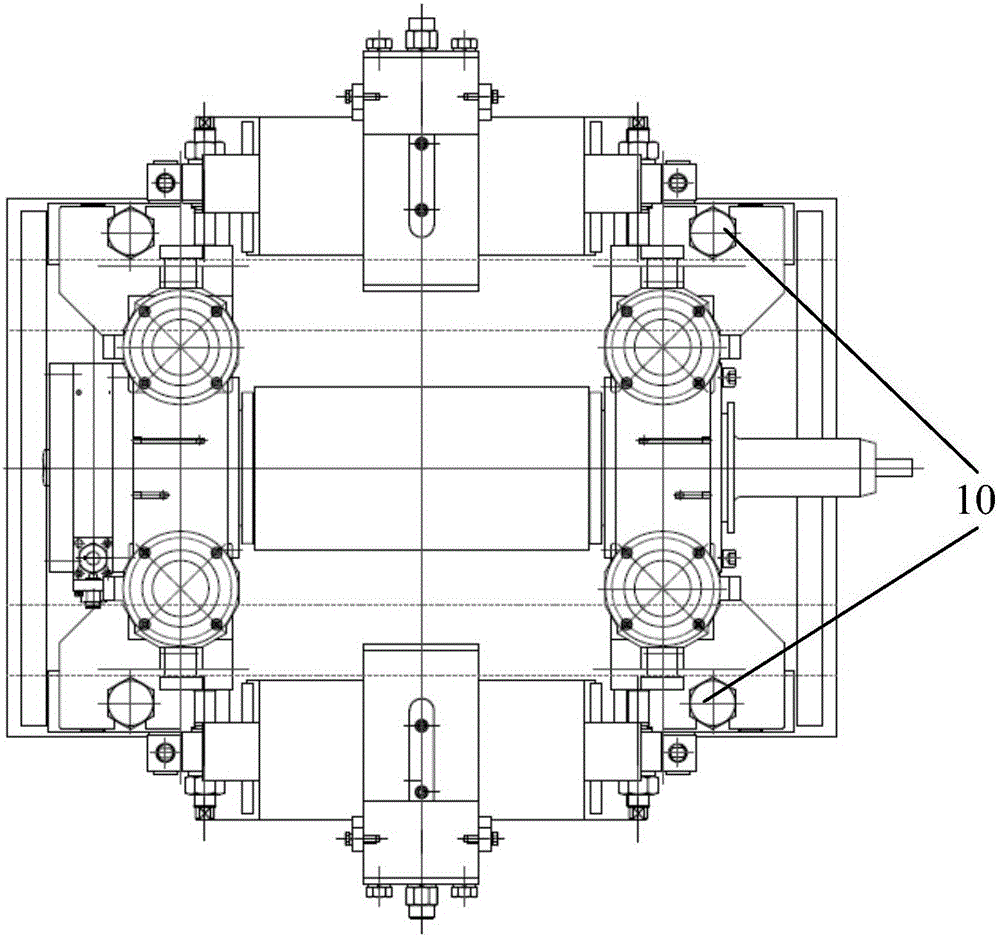

[0025] With reference to the accompanying drawings, the structural features and advantages of the present invention are described in detail as follows.

[0026] see Figure 2A , 2B And the schematic structural diagram of the general assembly drawing of the rolling mill of the present invention shown in 2C, the described high-precision rolling mill for bars includes a base 20, a roll system 30, and the roll system 30 is installed and fixed with the base through a support 32, for reference together Figure 3A , 3B and 3C. The column 21 of the rolling mill base 20 is provided with a conical hole 201 and four grooves 22, and an adjusting liner 202 is arranged in the groove 22; see Figure 4A , 4B And 4C, the four sides of the roller system support 32 are provided with a vertical boss structure 302, which matches with the four grooves 22 on the stand column 21 of the rolling mill base, as Figure 2B As shown, and adjust the position of the lining plate 202 by adjusting the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com