A kind of preparation method of micro-textured three-layer composite lubricating film

A lubricating film, microtexturing technology, applied in coatings, devices for coating liquids on surfaces, pretreatment surfaces, etc., can solve the problems of limited application, bonding strength, spreading degree and wear resistance of ionic liquid nano ultra-thin films. It can achieve the effect of simple preparation process, good application prospects, and improved tribological properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

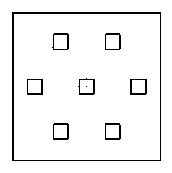

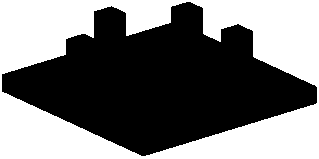

[0030] Example 1: The preparation of the micro-textured three-layer composite lubricating film of the square column regular hexagonal array is carried out in accordance with the following steps:

[0031] (1) Using inductively coupled plasma etching technology, the micro-textured regular morphology of square column regular hexagonal arrays with various geometric parameters is obtained on single crystal silicon wafers;

[0032](2) Dissociate the micro-textured single crystal silicon wafer into a size of 10mm×10mm, ultrasonically clean it in acetone, absolute ethanol and deionized water for 10min, and dry it with dry nitrogen. Then put it into the Piranha solution freshly prepared by 98% sulfuric acid and 30% hydrogen peroxide at a volume ratio of 7:3, keep it at 90°C for 30 minutes, rinse it repeatedly with deionized water, and blow it dry with nitrogen to obtain a micro-textured surface hydroxylation Monocrystalline silicon wafer;

[0033] (3) Dissolve (3-aminopropyl)trimethox...

Embodiment 2

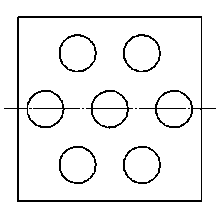

[0036] Embodiment 2: The preparation of the micro-textured three-layer composite lubricating film with the regular hexagonal array micro-texture of the pits is carried out according to the following steps:

[0037] (1) Using inductively coupled plasma etching technology, the micro-textured regular morphology of regular hexagonal arrays of pits with various geometric parameters is obtained on single crystal silicon wafers;

[0038] (2) Dissociate the micro-textured single crystal silicon wafer into a size of 10mm×10mm, ultrasonically clean it in acetone, absolute ethanol and deionized water for 10min, and dry it with dry nitrogen. Then put it into the Piranha solution freshly prepared by 98% sulfuric acid and 30% hydrogen peroxide at a volume ratio of 7:3, keep it at 90°C for 30 minutes, rinse it repeatedly with deionized water, and blow it dry with nitrogen to obtain a micro-textured surface hydroxylation Monocrystalline silicon wafer;

[0039] (3) Dissolve (3-aminopropyl)tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com