Tasteless tilmicosin particle and preparation method thereof

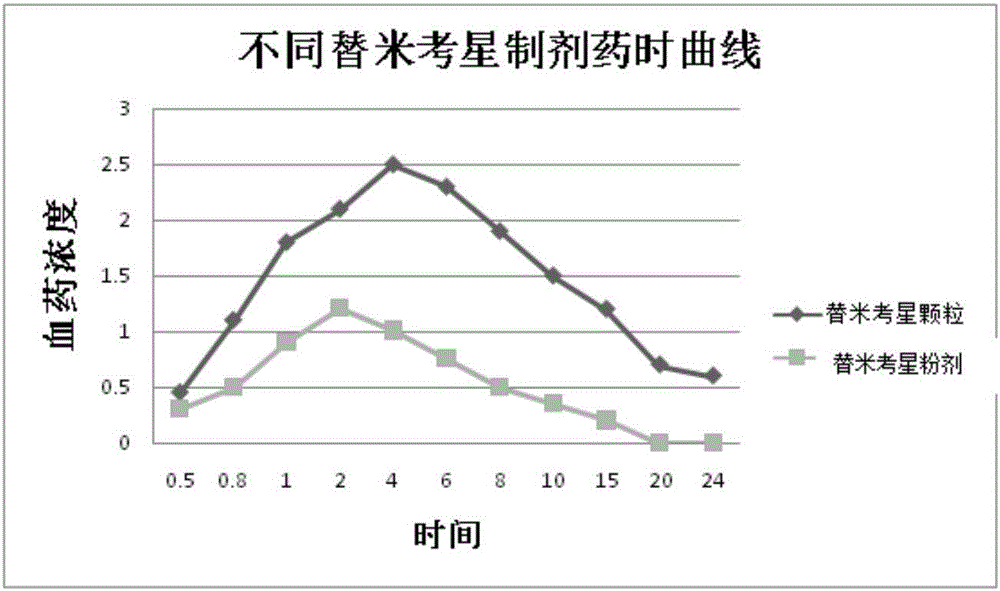

A technology of tilmicosin and granules, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve problems affecting palatability, vomiting, animal stimulation, etc., and achieve increased packaging Yield, the effect of prolonging the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A tilmicosin granule, every 100 granules contains 20 parts of tilmicosin, 30 parts of glyceryl stearate, 37 parts of magnesium stearate, 5 parts of sodium carboxymethyl starch, 6 parts of acrylic resin, twelve 2 parts sodium alkyl sulfate.

[0024] The preparation method of this tilmicosin particle, comprises the steps:

[0025] First weigh 20 parts of tilmicosin, add it into 30 parts of glyceryl stearate in a molten state at 80°C, and stir evenly. Add 37 parts of magnesium stearate and 5 parts of sodium carboxymethyl starch to the above mixture for granulation and spheronization. During the spheronization process, spray the second layer of enteric coating agent on the surface of the granules——6 parts of acrylic resin and A mixed solution of 2 parts of sodium lauryl sulfate is used to obtain approximately spherical particles with a particle diameter of 20-40 meshes, and then dried to obtain the final tilmicosin granule product.

Embodiment 2

[0027] A tilmicosin granule, every 100 granules contains 5 parts of tilmicosin, 5 parts of cetyl alcohol, 5 parts of stearyl alcohol, 65 parts of magnesium stearate, 10 parts of sodium carboxymethyl starch, 7 parts of acrylic resin Parts, 3 parts of sodium lauryl sulfate.

[0028] The preparation method of this tilmicosin particle, comprises the steps:

[0029] First weigh 5 parts of tilmicosin, add it into 5 parts of cetyl alcohol and 5 parts of stearyl alcohol in molten state at 65°C, and stir evenly. Add 65 parts of magnesium stearate and 10 parts of sodium carboxymethyl starch to the above mixture for granulation and spheronization. During the spheronization process, spray the second layer of enteric coating agent on the surface of the granules——7 parts of acrylic resin and 3 parts of sodium lauryl sulfate mixed solution to obtain approximately spherical particles with a particle diameter of 20 to 40 mesh, and then dry to obtain the final tilmicosin granule product.

Embodiment 3

[0031] A kind of tilmicosin granule, every 100 granules contains 10 parts of tilmicosin, 25 parts of glyceryl stearate, 49 parts of magnesium stearate, 8 parts of sodium carboxymethyl starch, 6 parts of acrylic resin, twelve 2 parts sodium alkyl sulfate.

[0032] The preparation method of this tilmicosin particle, comprises the steps:

[0033] First weigh 10 parts of tilmicosin, add it into 25 parts of glyceryl stearate in a molten state at 80°C, and stir evenly. Add 49 parts of magnesium stearate and 8 parts of sodium carboxymethyl starch to the above mixture for granulation and spheronization. During the spheronization process, spray the second layer of enteric coating agent on the surface of the granules——6 parts of acrylic resin and A mixed solution of 2 parts of sodium lauryl sulfate is used to obtain approximately spherical particles with a particle diameter of 20-40 meshes, and then dried to obtain the final tilmicosin granule product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com