Dispersed wind source directional air-blast electrostatic spraying machine

An electrostatic spraying and air blowing technology, which is applied in the device, application, animal husbandry, etc. of capturing or killing insects, can solve the problems of large distance difference, poor spray penetration, uneven application, etc., and achieve comprehensive spraying , The main body size is small, the effect of improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

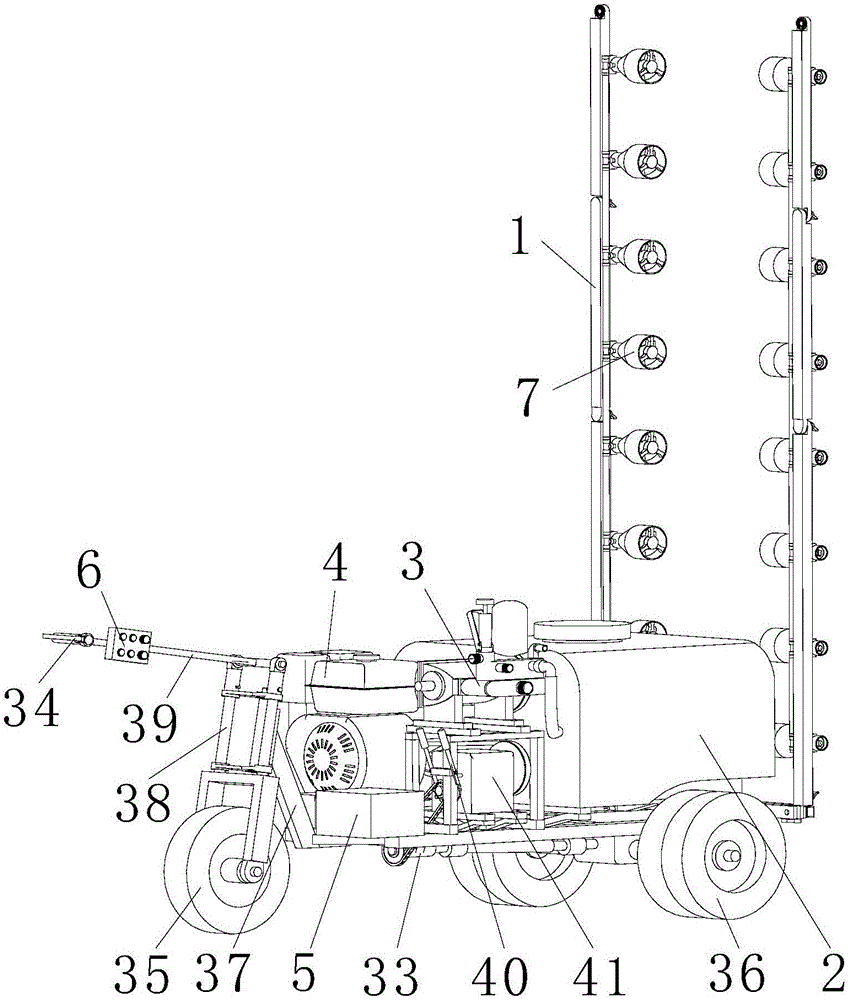

[0031] Such as figure 1 As shown, the present embodiment provides a decentralized wind source directional air-driven electrostatic sprayer, which includes a trolley, an adjustable boom frame 1, a medicine box 2, a liquid pump 3, a power system 4, and a power supply system 5 , an electric control system 6 and an air-driven electrostatic nozzle assembly 7, the adjustable spray boom frame 1, the medicine box 2, the liquid pump 3, the power system 4, the power supply system 5 and the electric control system 6 are all arranged on the trolley, There can be multiple wind-driven electrostatic spray head assemblies 7, and multiple wind-driven electrostatic spray head assemblies 7 are fixed on the adjustable spray boom frame 1.

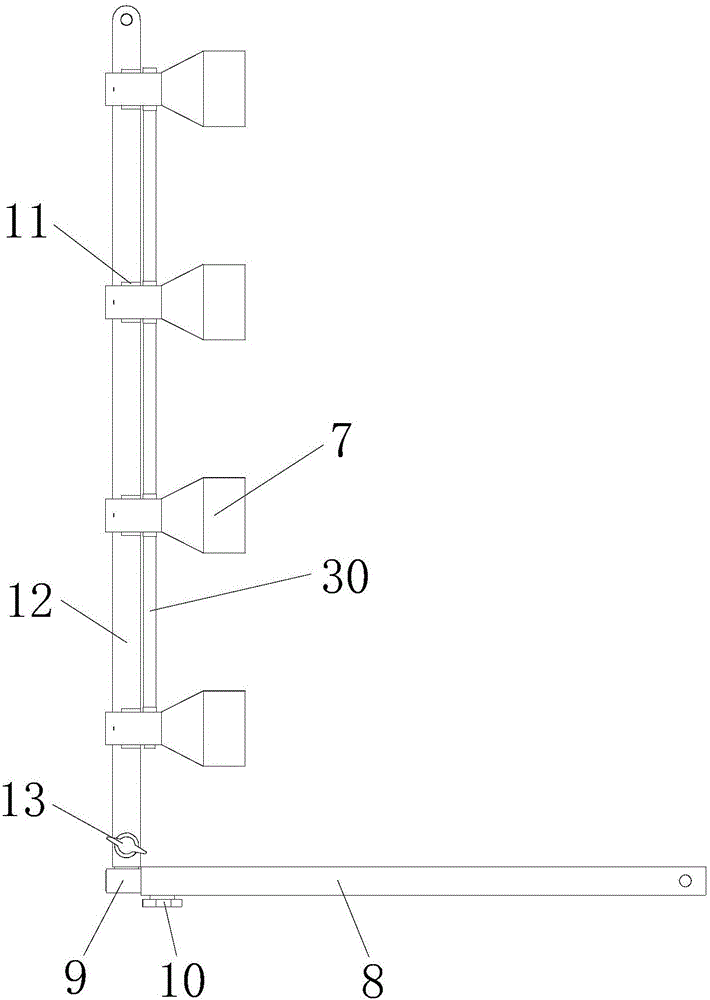

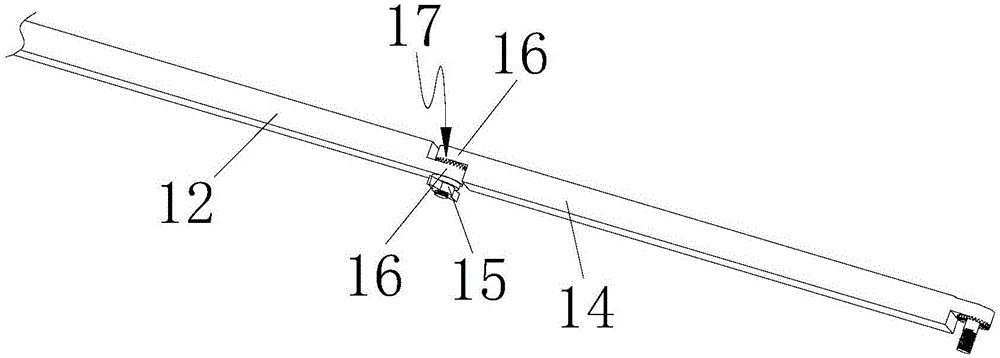

[0032] Such as figure 2 with image 3 As shown, the adjustable spray boom frame 1 includes a crossbar 8, two L-shaped poles 9 and two spray boom assemblies, and the two ends of the crossbar 8 are respectively sleeved on two One end of the L-shaped rod 9, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com