Supporting system for a heating element

A support system and heating unit technology, which is applied to furnace heating elements, electrical components, circuits, etc., can solve problems such as plastic deformation of heating units, achieve the effects of reducing mechanical stress, reducing risks, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

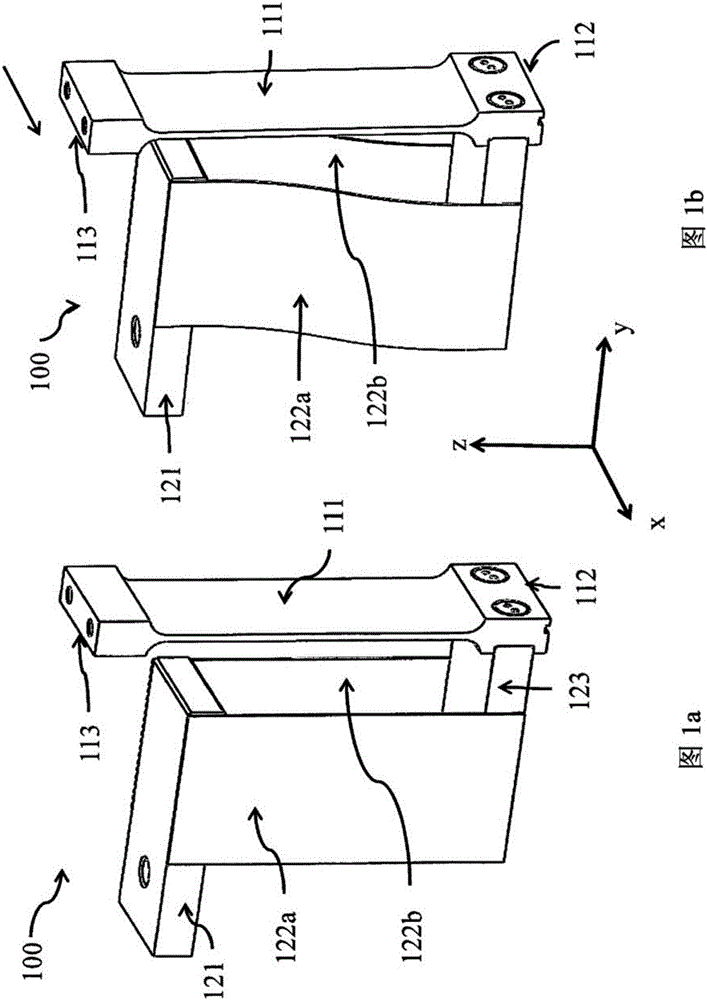

[0037] according to Figure 1a and Figure 1b The support system (100) of the embodiment in includes an elongated rigid support member (111) having a distal end (112) and a proximal end (113). On top of the rigid support member (111) is mounted a heating unit (not shown), the extension of which defines an extension plane. The main extension of the support member (111) extends in a height direction z which is perpendicular to the extension plane of the heating unit. The support system also comprises a base member (121) secured to a support plate (not shown), for example with screws or any other kind of mechanical fastener. A spring unit (122) is located between the support member (111) and the base member (121), and in this embodiment, the spring unit is implemented with at least two leaf springs (122a, 122b). The spring unit (122) is fixed to the distal end portion of the support member (111) by means of a rigid connection member (123) using screws, rivets, welding or other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com