Tapered roller bearing, method for producing the tapered roller bearing and method for securely mounting the tapered roller bearing

A technology for tapered roller bearings and rolling bearings, which is applied in the direction of roller bearings, shaft installation, bearing assembly, etc., and can solve the problem of dirt entering the inside of the bearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

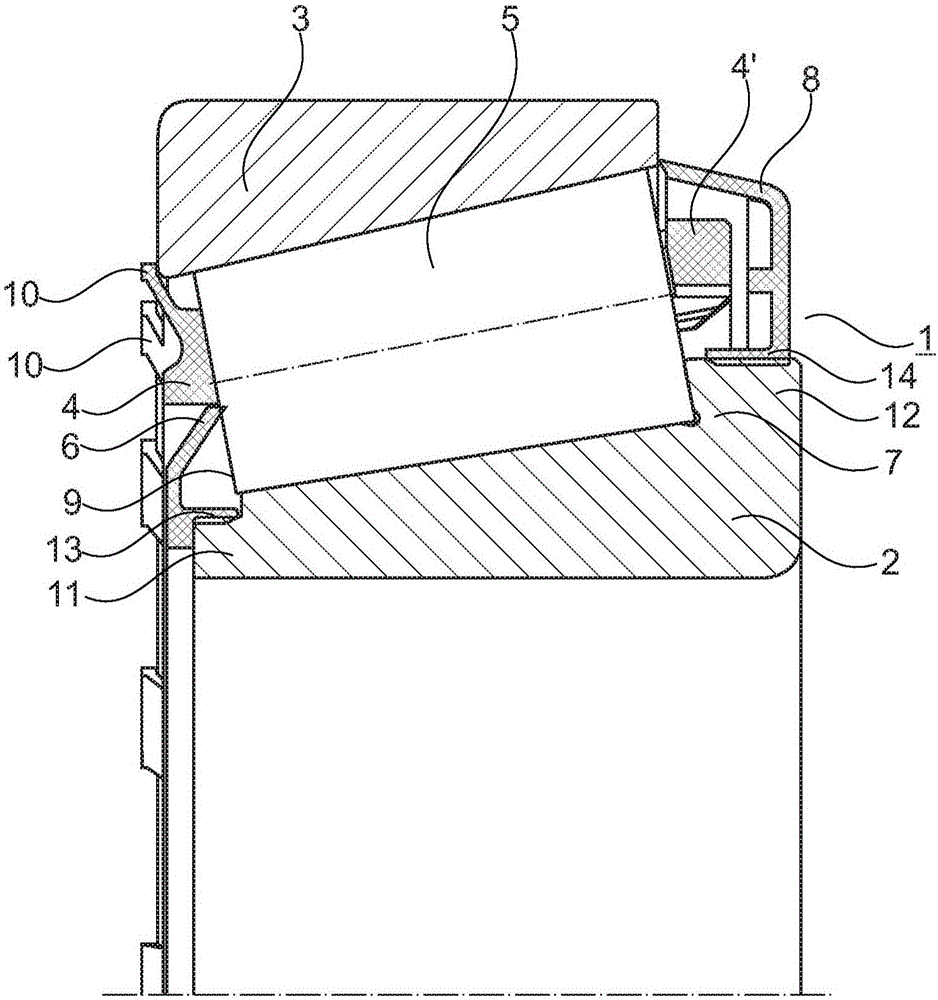

[0042] figure 1 A schematic section through a tapered roller bearing according to the invention is shown.

[0043] The tapered roller bearing 1 has an inner ring 2 , an outer ring 3 and a rolling bearing cage 4 with a number of rolling elements, of which only one rolling element 5 is shown. All rolling elements 5 are configured as tapered rollers. They are rotatably arranged between the inner ring 2 and the outer ring 3 .

[0044] Furthermore, a support mechanism 6 is provided. The support means 6 are designed to press the rolling bodies 5 in the direction of the support edge 7 of the inner ring 2 .

[0045] Furthermore, the rolling bearing cage 4 has a holding mechanism 10 for holding the outer ring 3 .

[0046] The support means 6 extends approximately annularly along the first region 11 of the inner ring 2 . The support means 6 has a section 13 which is connected to the first region 11 of the inner ring 2 . The connection of the support means 6 to the inner ring 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com