Electrically controlled magnetic energy high-efficient motor

A technology of electric control and magnetic energy, which is applied in the field of high-efficiency electric motor structure with electric control and magnetic energy, can solve problems such as laborious, small driving force attraction, and low-efficiency driving methods, and achieve the goals of eliminating urban smog, improving motor efficiency, and increasing mileage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

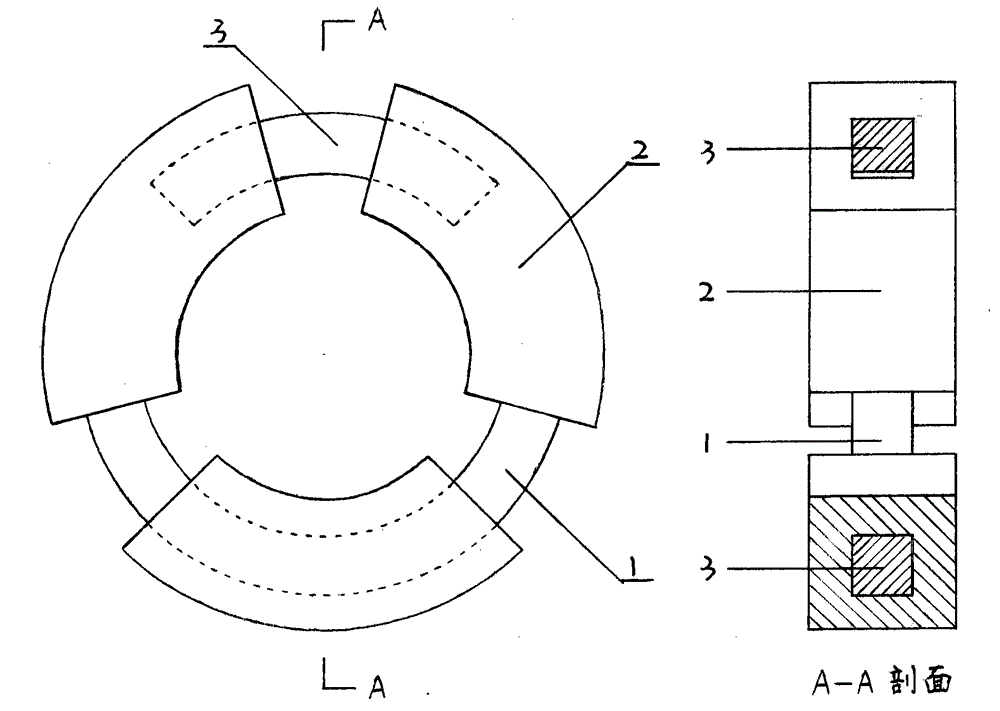

[0020] The electronically controlled magnetic energy high-efficiency motor involved in the present invention only discloses a basic structure and driving mode, and the specific structures of the electronically controlled magnetic energy efficient motor designed and manufactured using it are varied. This embodiment only provides a schematic diagram of its basic structure, and the specific structures are various, which do not constitute a limitation to the present invention.

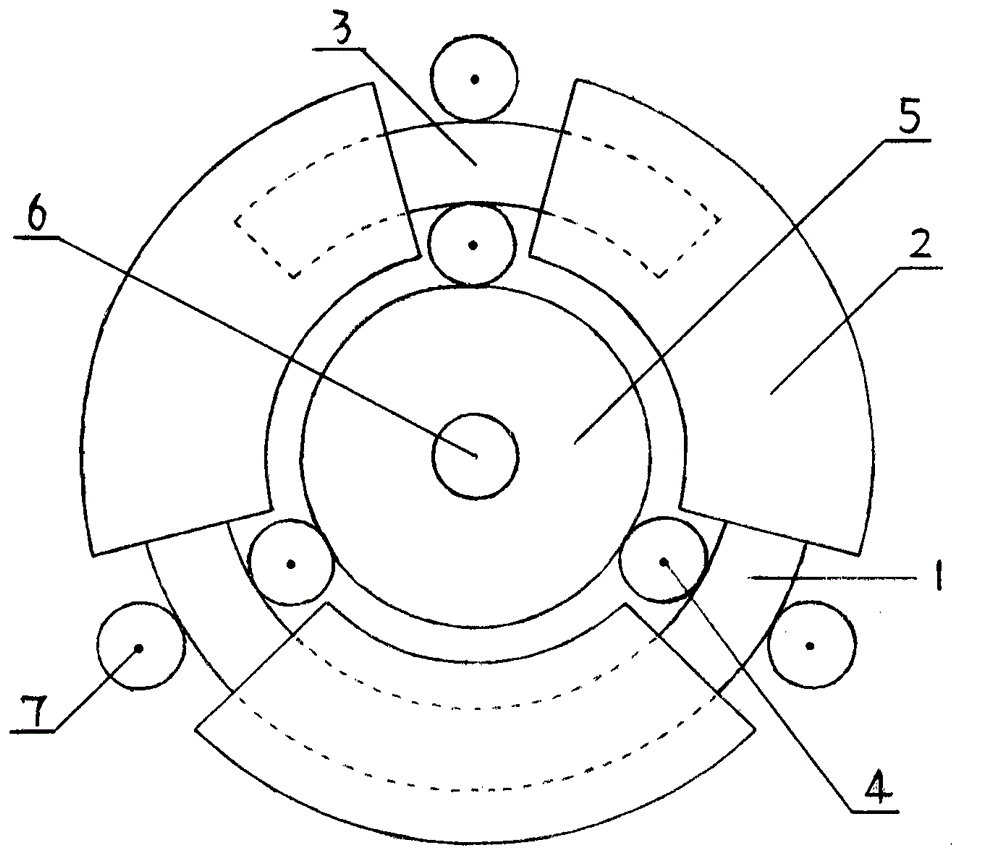

[0021] figure 2 Among them, a gear drive plate is installed on the inner ring surface of the annular rotor (1) (the figure is only for illustration, not realistic), the electromagnetic control coil (2) is fixed on the casing as the stator, and the shaft of the intermediate transmission wheel (4) and The output shaft (6) is fixed on the casing through bearings, and the three intermediate transmission wheels (4) also play the role of limiting the inner ring surface of the annular rotor (1), preventing it fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com