A laser annealing device and annealing method with energy compensation

A technology of laser annealing and energy compensation, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of affecting the overlay accuracy, large thermal deformation of silicon wafers, and long dwell time, avoiding pattern effects, dwell time and other problems. The effect of short residence time and reducing the effect of overlay accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

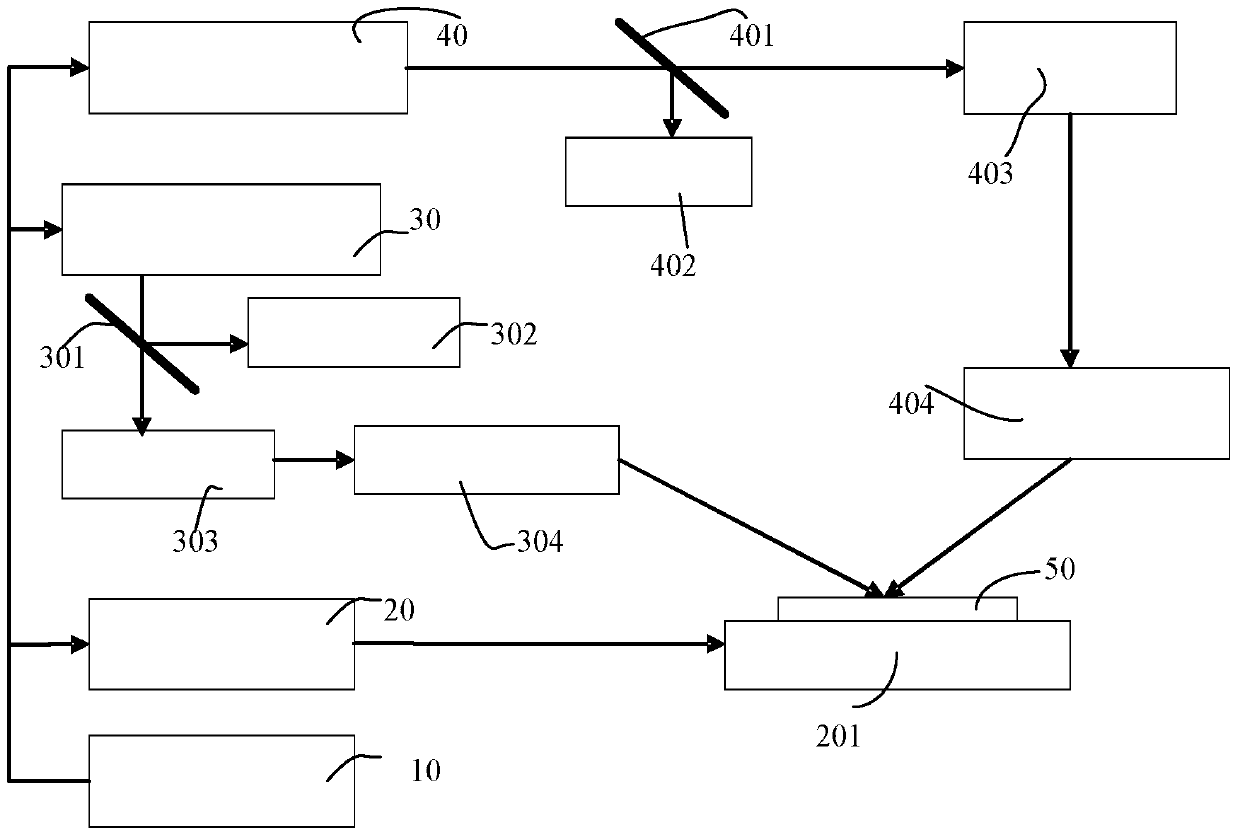

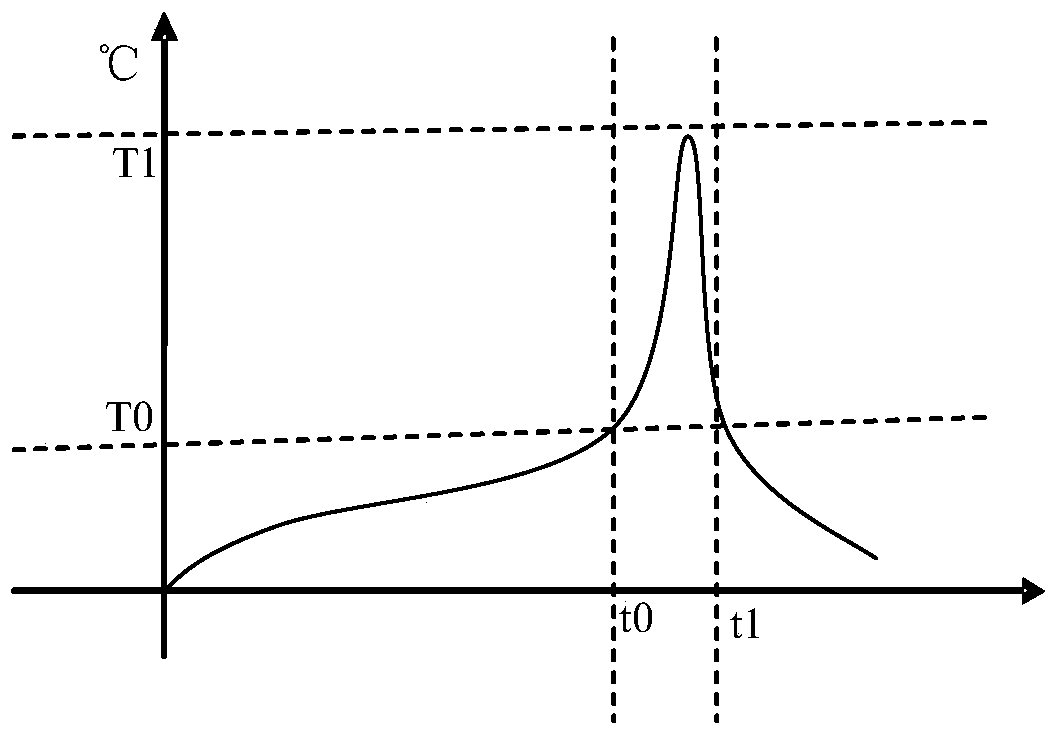

[0038] Please refer to figure 1 , a laser annealing device with energy compensation, comprising a loading table 201 for carrying a silicon wafer 50, driving the silicon wafer 50 for scanning annealing, and also including

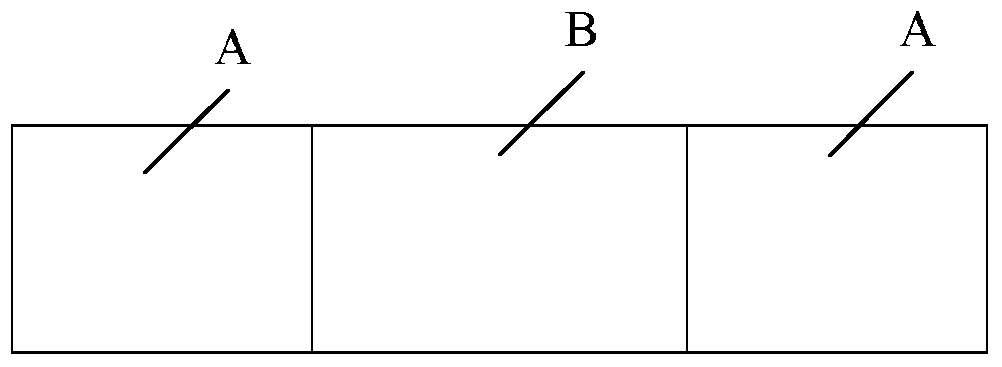

[0039] The infrared laser 303 is used to emit infrared laser. The infrared laser uses Brewster's angle to preheat the silicon wafer 50. The infrared laser can be a pulsed laser or a continuous laser.

[0040] An infrared optical system 304, configured to perform optical system shapin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com