Five-degree-of-freedom outer rotor permanent magnet bias spherical magnetic bearing

A technology of permanent magnetic bias and external rotor, which is applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of not considering the axial control, difficulty in meeting the application occasions, reducing the control accuracy of the rotor, etc., and achieve power consumption Low, simple structure, and the effect of increasing the number of degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

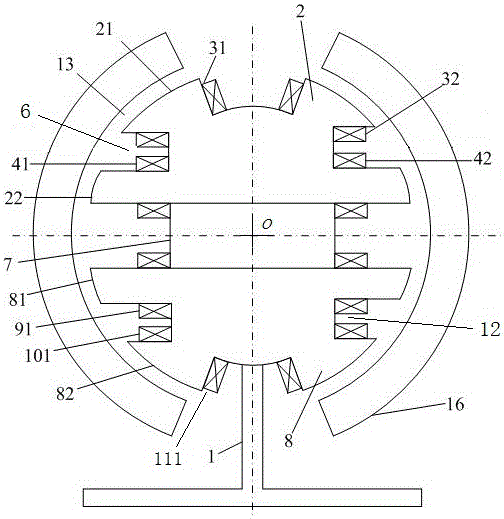

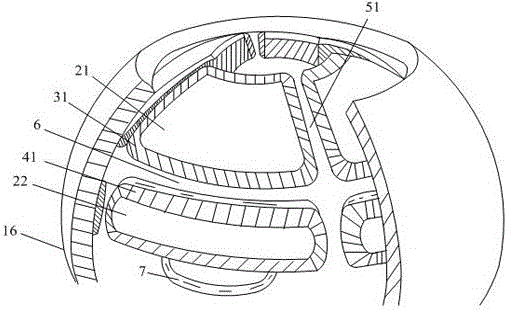

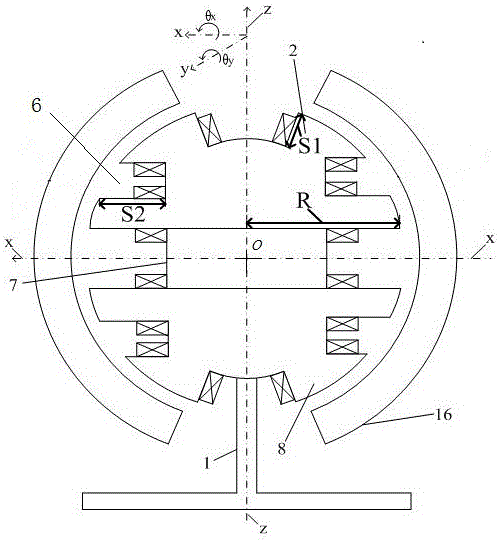

[0023] Such as figure 1 As shown, the present invention consists of a rotating shaft 1, two stators, a permanent magnet 7, a rotor 16 and control coils. The rotor 16 is spherical, and a permanent magnet 7 and two stators are located in the center of the rotor 16. The upper and lower parts of the rotor 16 each have an opening. The longitudinal shaft 1 extends into the rotor 16 from the lower opening of the rotor 16 and passes through a permanent magnet. 7 and the longitudinal through hole in the middle of the two stators, a permanent magnet 7 and the two stators are all empty sleeves on the rotating shaft 1. The central axes of the upper and lower openings on the rotor 16, the central axes of a permanent magnet 7 and the two stators coincide with the central axes of the rotating shaft 1, and all pass through the center of the rotor 16 o .

[0024] The two stators are respectively an upper stator 2 and a lower stator 8, both of which are hemispherical and have identical struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com