Aluminum profile corner adjustable in field joint

A technology for installing joints and aluminum profiles, which is applied in the field of aluminum profile corners, can solve the problems that the concave joints of color steel sandwich panels cannot match the convex joints of aluminum profile corners, etc., and achieve the effect of simple structure and firm rubber seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

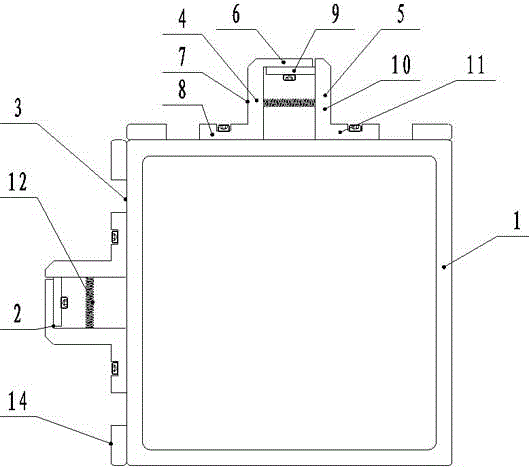

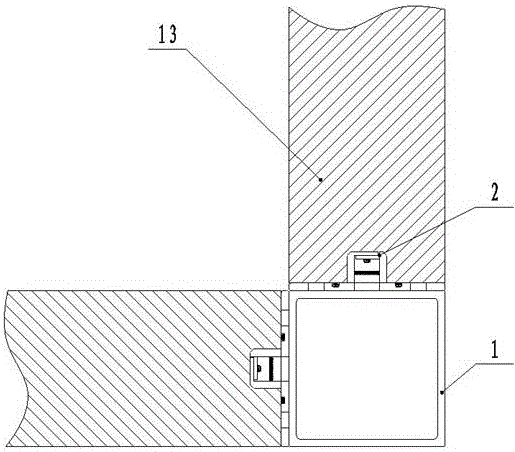

[0017] Such as Figure 1-2 As shown, the present invention has an aluminum profile corner with an adjustable installation joint, including a corner substrate frame 1 and an adjusting convex joint 2, and the adjusting convex joint 2 is arranged on two adjacent corner surfaces 3 of the corner substrate frame 1, so that The adjusting male joint 2 described above includes a first male joint frame plate 4 and a second male joint frame plate 5, and the first male joint frame plate 4 includes a first connecting horizontal plate 6, a first vertical plate 7 and a first The base plate 8 is installed, and the second male joint frame plate 5 includes a second connecting horizontal plate 9, a second vertical plate 10 and a second mounting base plate 11, and the first connecting horizontal plate 6 and the first connecting horizontal plate 6 on the first male joint frame plate 4 The second connecting horizontal plate 9 on the two-convex joint frame plate 5 overlaps and connects by bolts, the...

Embodiment 2

[0021] Such as Figure 1-2 As shown, the present invention can adjust the corner of the aluminum profile for installing joints. On the basis of Embodiment 1, a tension spring 12 is arranged between the first male joint frame plate 4 and the second male joint frame plate 5 . By providing a tension spring 12 between the first convex joint frame plate 4 and the second convex joint frame plate 5, after the concave interface of the color steel sandwich plate 13 and the aluminum profile corner convex joint are glued and window-sealed, The tension of the tension spring 12 can make the rubber seal more firm, and it is also conducive to the tight clamping of the concave interface of the color steel sandwich panel 13 and the corner convex joint of the aluminum profile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com