Molded product manufacturing method and finished molded product

A manufacturing method and product technology, applied in the field of manufacturing methods and finished products of molded products, can solve the problems of lowering the sense of value of goods, difficulty in increasing the thickness, and poor visual perception, and achieve the effect of increasing the sense of value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

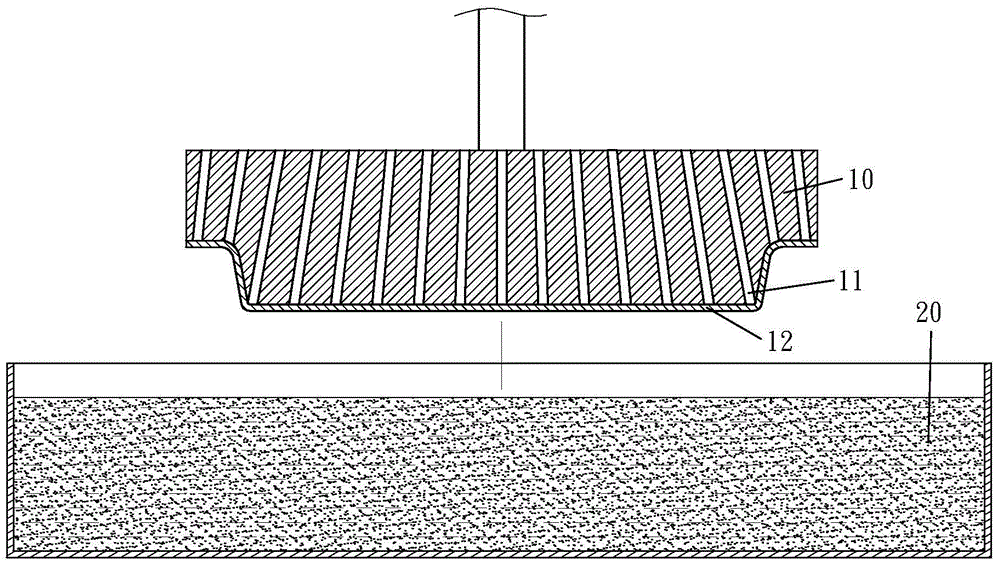

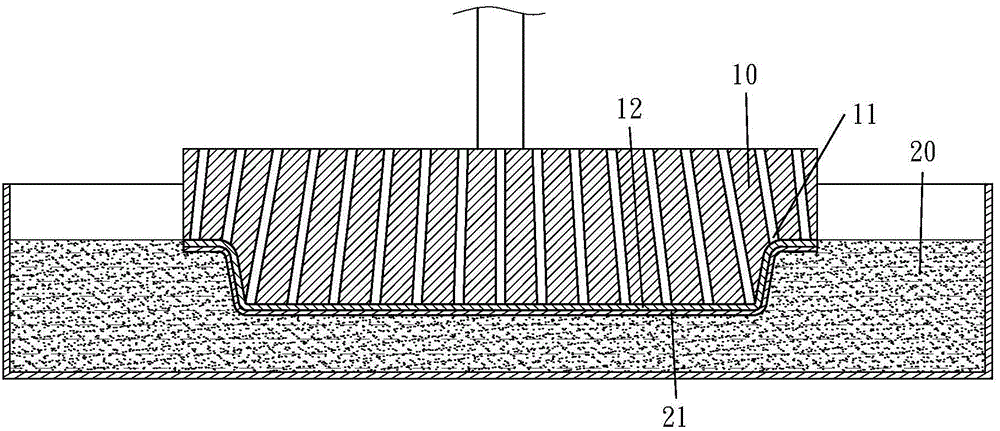

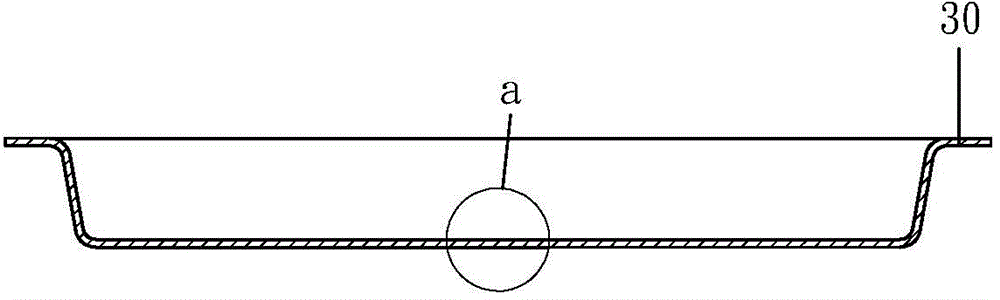

[0053] see Figure 5 As shown, the present invention enters the pulp box 20 simultaneously by an upper slurry suction mold 40 and a lower slurry suction mold 50 (it can be the same slurry box or different slurry boxes, and is not limited), and the vacuum suction effect passes through the upper suction cavity. Most of the pulp suction holes 41, 51 on the slurry mold 40 and the lower slurry suction mold 50 absorb the slurry simultaneously, so that an upper slurry layer 22 is formed and attached to the outer surface of the fine metal mesh 42 on the surface of the upper slurry suction mold 40, and at the same time Form the slurry layer 23 attached to the outer surface of the fine metal mesh 52 on the surface of the lower slurry suction mold 50, wherein the fine metal mesh 42 provided on the upper slurry suction mold 40 and the fine metal mesh 42 provided on the lower slurry suction mold 50 The metal mesh 52 has part of the shape and the same position, and some of the shape and pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com